A kind of silicone resin-based laser protective coating and preparation method thereof

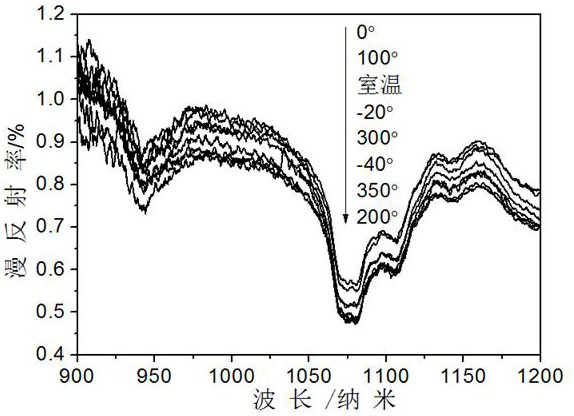

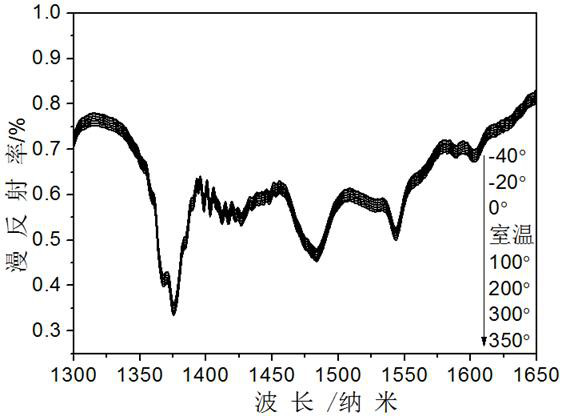

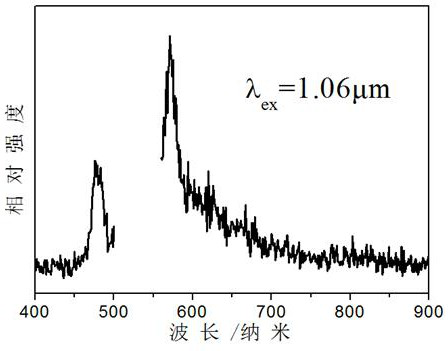

A laser protection and organic silicon technology, applied in coatings and other directions, can solve the problems of less research on laser protection materials and few high temperature resistant laser protection coating materials, etc., to enhance the laser protection ability and improve the absorption of light. , the effect of increasing the carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A silicone resin-based laser protection coating, the substrate of the coating is a high temperature resistant self-drying silicone resin, and the filler is (Sm 0.895 Er 0.005 mn 0.1 )BO 3 , the mass ratio of filler to matrix is 0.75, filler (Sm 0.895 Er 0.005 mn 0.1 )BO 3 Prepared by citric acid-nitrate sol-gel combustion synthesis method, comprising the following steps:

[0037] (1) Weigh 19.917gSm(NO 3 ) 3 ·6H 2 O, 0.111gEr(NO 3 ) 3 ·5H 2 O, 1.257gMn(NO 3 ) 2 4H 2 O, 3.096g boric acid and 21.041g citric acid are placed in the beaker, add distilled water and stir to form a transparent sol;

[0038] (2) Seal the beaker and heat it on a constant temperature magnetic stirrer at 60°C while stirring and refluxing for 0.5h;

[0039] (3) Unseal the seal and continue to stir while heating on a constant temperature magnetic stirrer at 80°C to evaporate the water continuously until a transparent gel is formed;

[0040] (4) Place the beaker containing the trans...

Embodiment 2

[0048] A silicone resin-based laser protection coating, the substrate of the coating is a high temperature resistant self-drying silicone resin, and the filler is (Sm 0.85 Er 0.01 mn 0.14 )BO 3 , the mass ratio of filler to matrix is 0.8, filler (Sm 0.85 Er 0.01 mn 0.14 )BO 3 Prepared by citric acid-nitrate sol-gel combustion synthesis method, comprising the following steps:

[0049] (1) Weigh 20.296gSm(NO 3 ) 3 ·6H 2 O, 0.113gEr(NO 3 ) 3 ·5H 2 O, 1.281gMn(NO 3 ) 2 4H 2 0, 3.154g boric acid and 30.018g citric acid are placed in the beaker, add distilled water and stir to form a transparent sol;

[0050] (2) Seal the beaker and heat it on a constant temperature magnetic stirrer at 70°C while stirring and refluxing for 1 hour;

[0051] (3) Unseal the seal and continue to stir while heating on a constant temperature magnetic stirrer at 75°C to evaporate the water continuously until a transparent gel is formed;

[0052] (4) Place the beaker containing the transp...

Embodiment 3

[0060] A silicone resin-based laser protection coating, the substrate of the coating is a high temperature resistant self-drying silicone resin, and the filler is (Sm 0.815 Er 0.015 mn 0.17 )BO 3 , the mass ratio of filler to matrix is 0.9, filler (Sm 0.815 Er 0.015 mn 0.17 )BO 3 Prepared by citric acid-nitrate sol-gel combustion synthesis method, comprising the following steps:

[0061] (1) Weigh 20.588gSm(NO 3 ) 3 ·6H 2 O, 0.115gEr(NO 3 ) 3 ·5H 2 O, 1.299gMn(NO 3 ) 2 4H 2 0, 3.200g boric acid and 39.150g citric acid are placed in a beaker, add distilled water and stir to form a transparent sol;

[0062] (2) Seal the beaker and heat it on a constant temperature magnetic stirrer at 75°C while stirring and refluxing for 1.5 hours;

[0063] (3) Unseal the seal and continue to stir while heating on a constant temperature magnetic stirrer at 70°C to evaporate the water continuously until a transparent gel is formed;

[0064] (4) Put the beaker containing the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com