Cylindrical hollow drilling tool

A technology for drilling tools and cylinders, which is applied to the field of hollow drilling tools for forming cylinders at one time, can solve the problems that the connection gap affects the appearance, the shape does not meet the requirements, and the processing time is long, so as to achieve light and flexible use and low air pollution. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

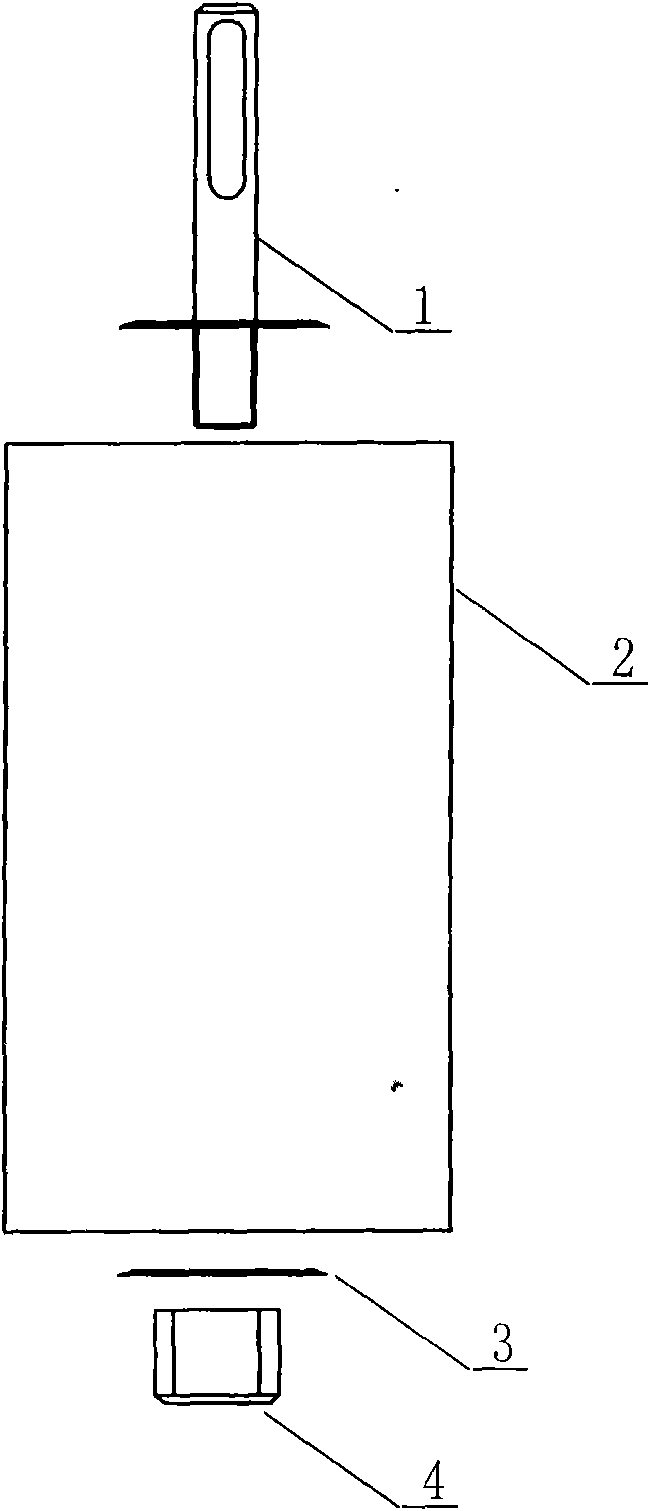

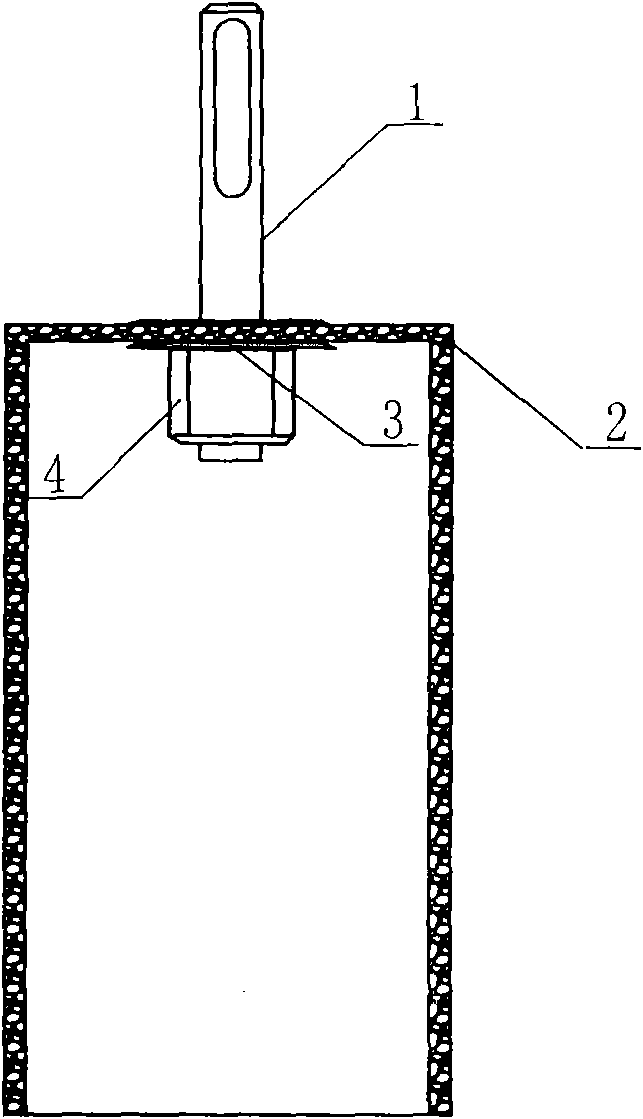

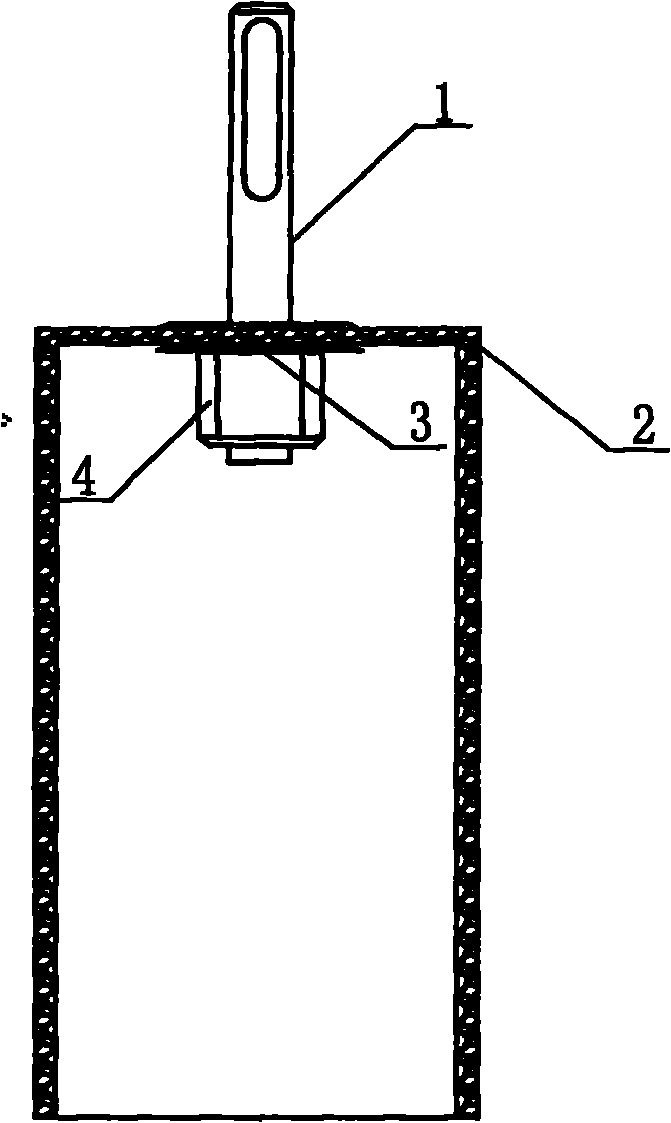

[0012] Such as figure 1 , figure 2 The cylindrical hollow drilling tool shown in includes drill shank 1, drill body 2, lower gasket 3, and tightening screw 4. When the radius R of the pipe to be processed on the construction site is 50mm, the radius size R of the cutting surface of the drill body 2 is also selected to be 50mm , the height H of the drill body 2 cylinder is selected to be 150mm, the tail of the drill shank 1 passes through the mounting surface of the drill body 2, the lower gasket 3 is inserted into the lower part of the drill shank 1 inside the drill body 2, and the tightening screw 4 Tighten it and fix it into a cylindrical hollow drilling tool. The head of drill shank 1 adopts the common clamping structure of existing drill bits, so that it can be used with hand-held or bench-top drilling tools. Through the high-speed rotation of hand-held or bench-top drilling tools, the drill The body 2 rotates the chip pipe at high speed, and can form the required circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com