Polyethylene glycol-copolyester segmented copolymer material capable of preventing adhesion, a preparation method and application thereof

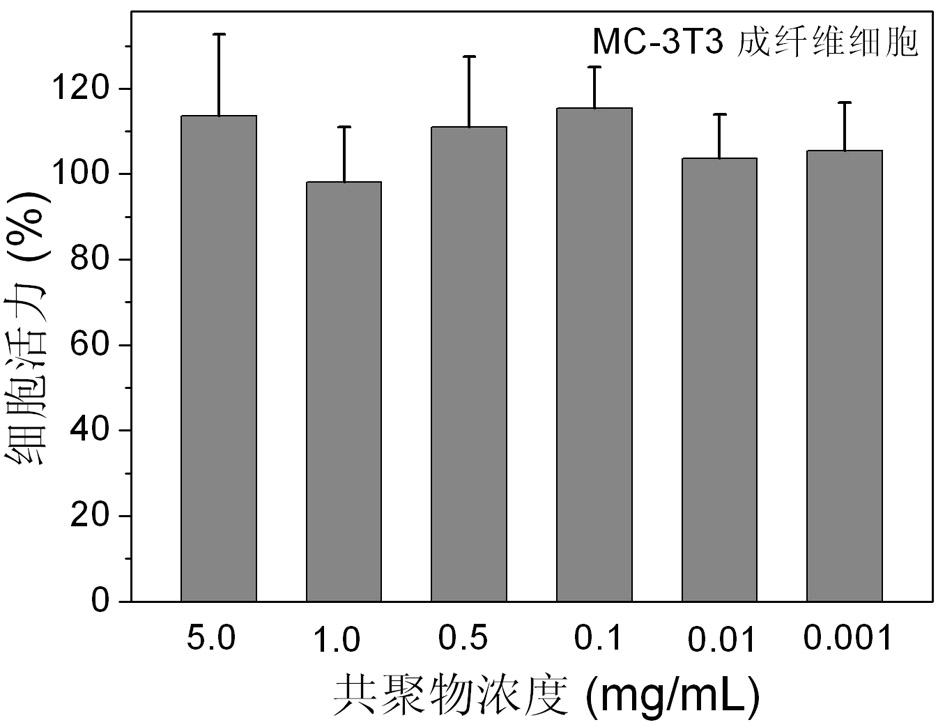

A polyethylene glycol and block polymer technology, applied in medical science, surgery, etc., can solve the problems of pH imbalance, aseptic inflammatory reaction, irritation, etc., achieve good biocompatibility, convenient operation and application, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

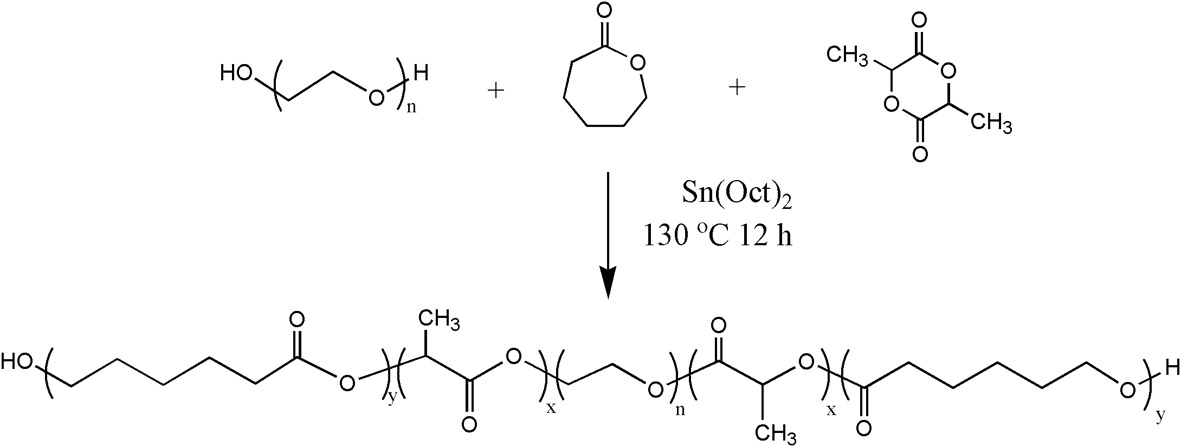

[0033] Embodiment 1: Synthesis of PCLA-PEG-PCLA block copolymer

[0034]Add 28 g of PEG (molecular weight: 1500) into a 500 ml three-neck flask, heat the oil bath to 120 oC, and vacuum pump for three hours while stirring to remove residual moisture in the PEG. In order to reduce the volatilization of CL monomer, firstly lower the temperature to 80 oC, then add 28 g of caprolactone (CL) and 36 g of lactide (LA) under the protection of argon, heat it under vacuum to make it melt completely, and then continue to remove water for an hour. Add 15 mg of stannous isooctanoate, and the oil bath is heated to 130° C. to continue the reaction for 12 hours. After the reaction is complete, dissolve the initial product in cold water (5 oC ~ 8 oC). After it is completely dissolved, the temperature of the solution is raised to 80 oC, the product precipitates, and the upper solution is removed. Repeat the above steps once to obtain the initial product. Water was removed by lyophilization in ...

Embodiment 2

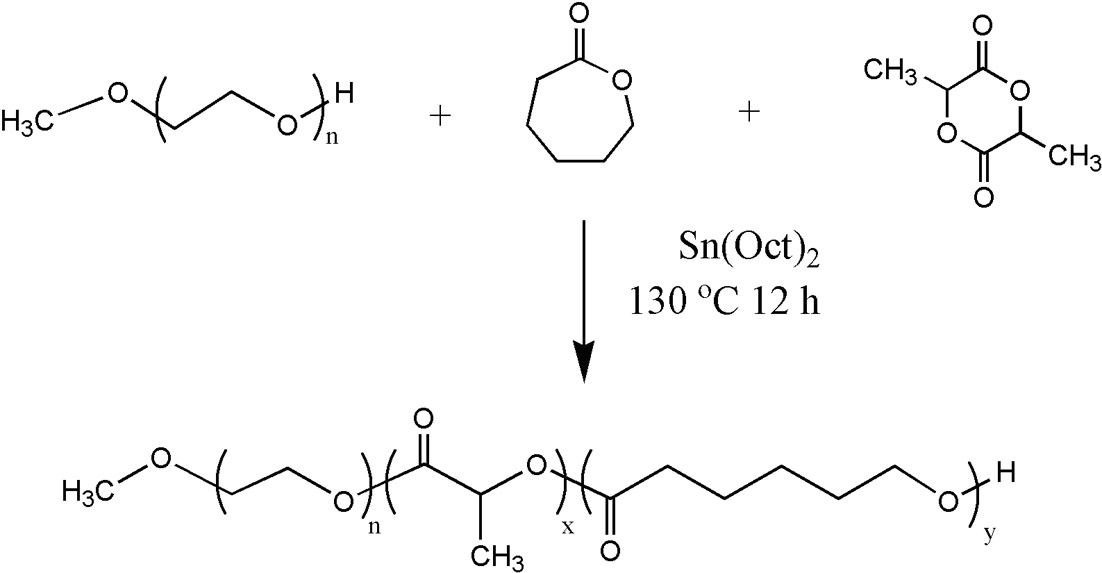

[0035] Example 2: Poly(caprolactone 1,4,8-trioxaspiro[4.6]-9-undecanone)-polyethylene glycol-poly(caprolactone-1,4,8-trioxa spiro[4.6]-9-undecanone) P(CL-TOSUO)- b -PEG- b - Synthesis of P(CL-TOSUO)

[0036] Add 15 g of PEG (molecular weight: 1500) into a 500 ml three-neck flask, heat the oil bath to 120 oC, and vacuum pump for three hours while stirring to remove the residual moisture in the PEG. In order to reduce the volatilization of CL monomer, the temperature was first lowered to 80 oC, and then 33 g of caprolactone (CL) and 10 g of 1,4,8-trioxaspiro[4.6]-9- Undecanone TOSUO, after heating under vacuum to completely melt, continue to remove water for one hour. Add 15 mg of stannous isooctanoate, and the oil bath is heated to 130° C. to continue the reaction for 12 hours. After the reaction is complete, dissolve the initial product in cold water (5 oC ~ 8 oC). After it is completely dissolved, the temperature of the solution is raised to 80 oC, the product precipitate...

Embodiment 3

[0037] Example 3: Synthesis of polycaprolactone-glycolide-polyethylene glycol-polycaprolactone-glycolide (PCGA-PEG-PCGA) block copolymer

[0038] Add 14 g PEG (molecular weight 1500) into a 500 ml three-neck flask, heat the oil bath to 120 oC, and vacuum pump for three hours while stirring to remove the residual moisture in the PEG. In order to reduce the volatilization of CL monomer, firstly lower the temperature to 80 oC, then add 14 g caprolactone (CL) and 18 g glycolide (GA) under the protection of argon, heat it under vacuum to make it melt completely, and then continue to remove water for an hour. Add 15 mg of stannous isooctanoate, and the oil bath is heated to 130° C. to continue the reaction for 12 hours. After the reaction is complete, dissolve the initial product in cold water (5 oC ~ 8 oC). After it is completely dissolved, the temperature of the solution is raised to 80 oC, the product precipitates, and the upper solution is removed. Repeat the above steps once t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com