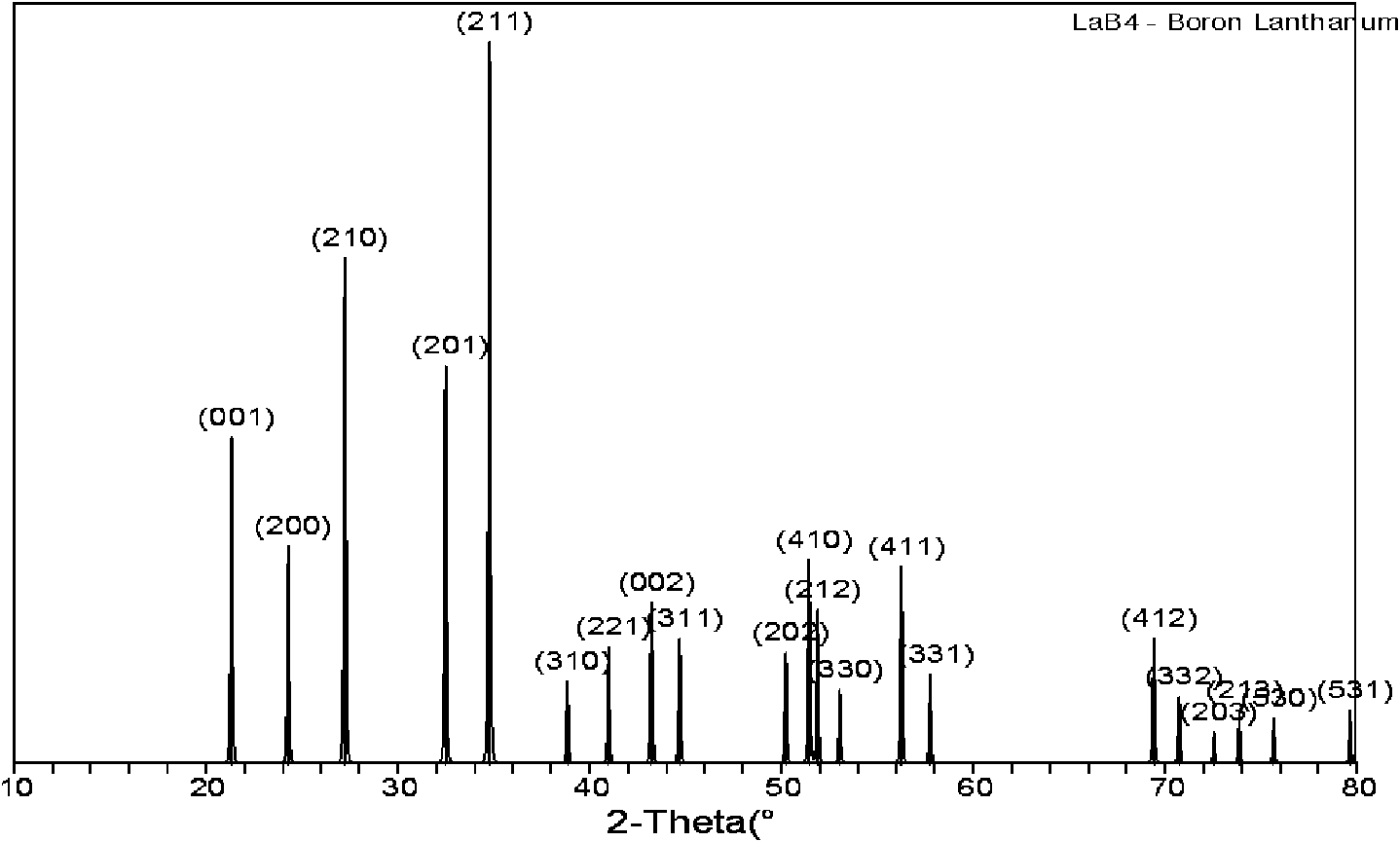

Synthesis method of nano rare-earth tetraboride and applications thereof

A technology of nano-rare earth and synthesis method, applied in the direction of boron/boride, metal boride, etc., to achieve the effects of easy removal, lower energy consumption, and lower synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

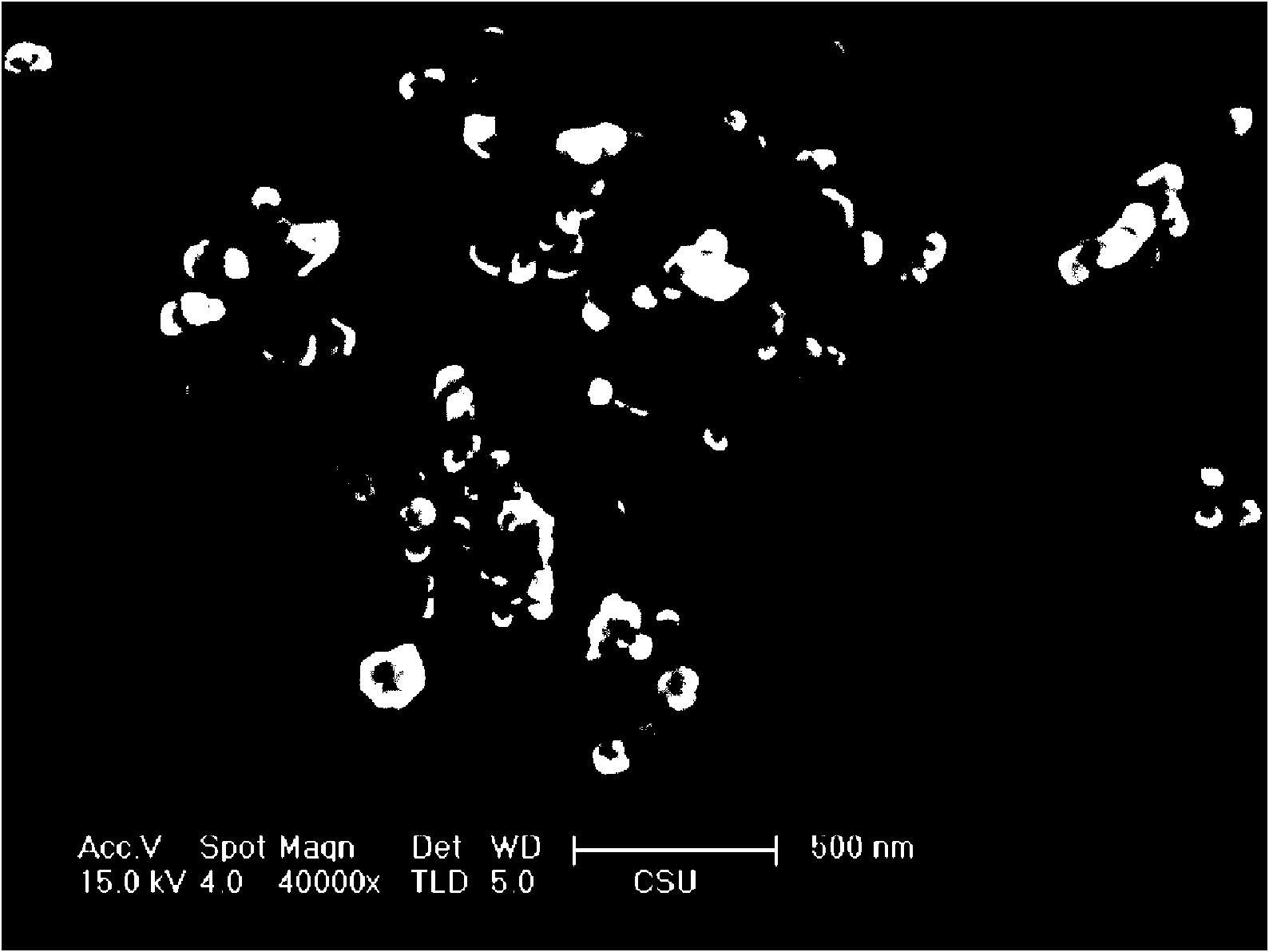

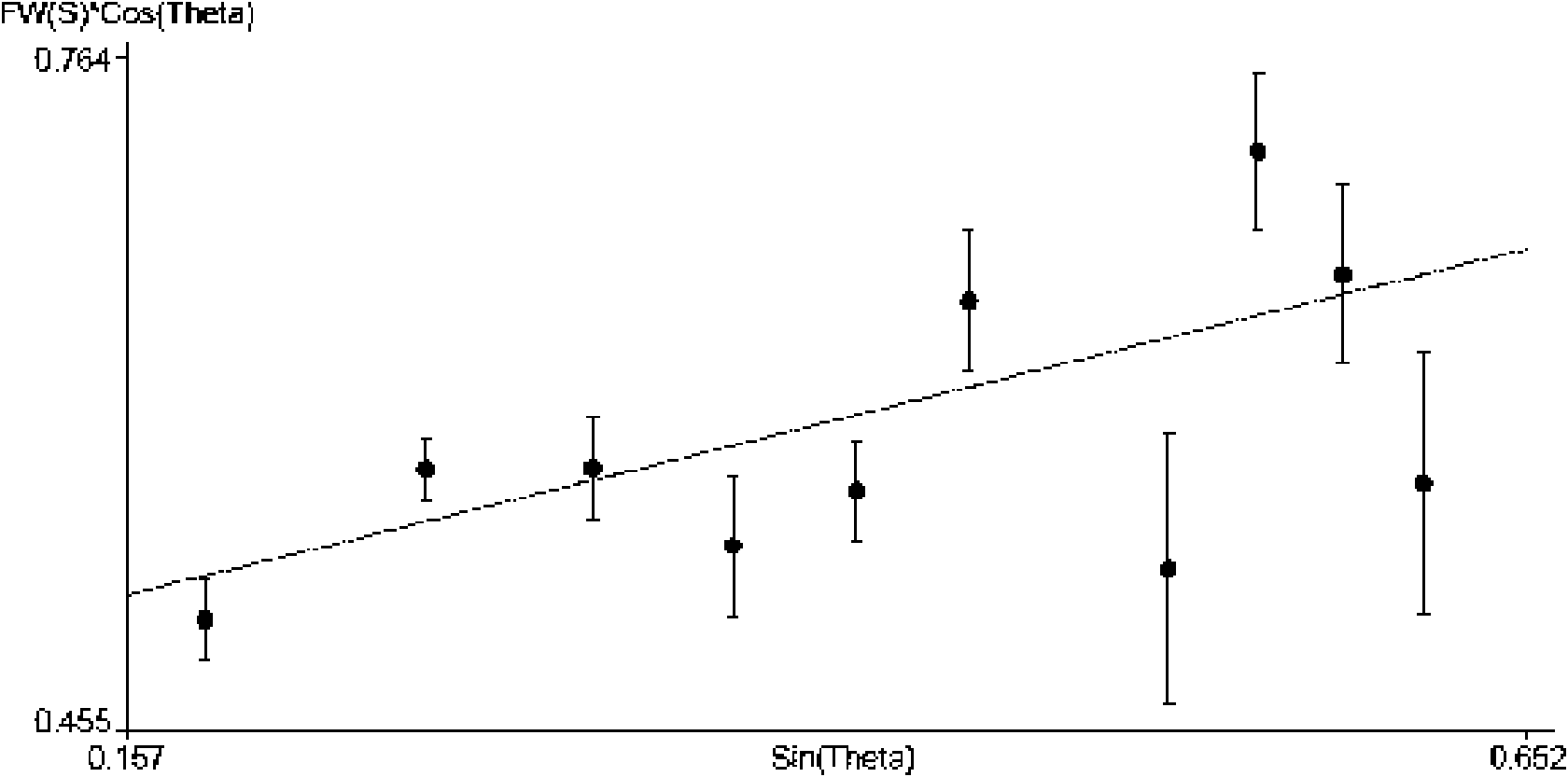

[0031] Weigh chemically pure raw materials in proportion: 162.9g La 2 o 3 , 118.4g C 2 Cl 6 and 215.8g KBH 4 ,

[0032] Mix the raw materials in a planetary ball mill for 1 hour, the ball-to-material ratio is 4:1, the rotating speed is 250RPM, and all the mixed powders pass through a 100-mesh sieve; the above ball-milled mixture is molded into a disc with a diameter of 100mm, Put it into an industrial microwave oven, pre-evacuate the microwave reaction furnace to 10Pa, and then feed 99.99% Ar gas, and the gas flow rate during the synthesis process is 0.5LPM. Use microwave power to control the heating rate, heat at 200°C for 1 hour, then heat at 650°C for 4 hours, cool to room temperature with the furnace, and take out the synthesized product from the dry inert atmosphere. Put the synthetic product into the pre-prepared 800ml HCl aqueous solution with a mass concentration of 3% and stir to dissolve the by-products in the synthetic material, while the nanometer lanthanum te...

Embodiment 2

[0036] Weigh chemically pure raw materials in proportion: 181.3g Gd 2 o 3 , 118.4g C 2 Cl 6 and 151.4 g NaBH 4 ,

[0037] Mix the raw materials in a planetary ball mill for 2 hours, the ratio of balls to materials is 5:1, and the speed is 200RPM. All the mixed powders pass through a 140-mesh sieve; the above ball-milled mixture is molded into a disc with a diameter of 100mm. Put it in an industrial microwave oven, pre-evacuate the microwave reaction furnace to 5Pa, and then pass 99.99% N 2Gas, the gas flow rate during the synthesis process was 0.5 LPM. Use microwave power to control the heating rate, heat at 190°C for 2 hours, then heat at 600°C for 5 hours, cool to room temperature with the furnace, and take out the synthesized product from the dry inert atmosphere. It is the HCl aqueous solution stirring of 4% that the synthetic product is put into pre-equipped 700ml mass concentration to make the by-product dissolving in the synthetic material, and nano gadolinium tet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Average crystallite size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com