A heating component of an electronic cigarette vaporizer

A technology of electronic cigarette atomizer and heating components, which is applied in the fields of tobacco, smoker’s products, applications, etc. It can solve the problems of difficult diffusion of smoke, difficulty in assembly, and low atomization efficiency, so as to reduce the loss of smoke and improve the taste of smoke , Improve the effect of atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

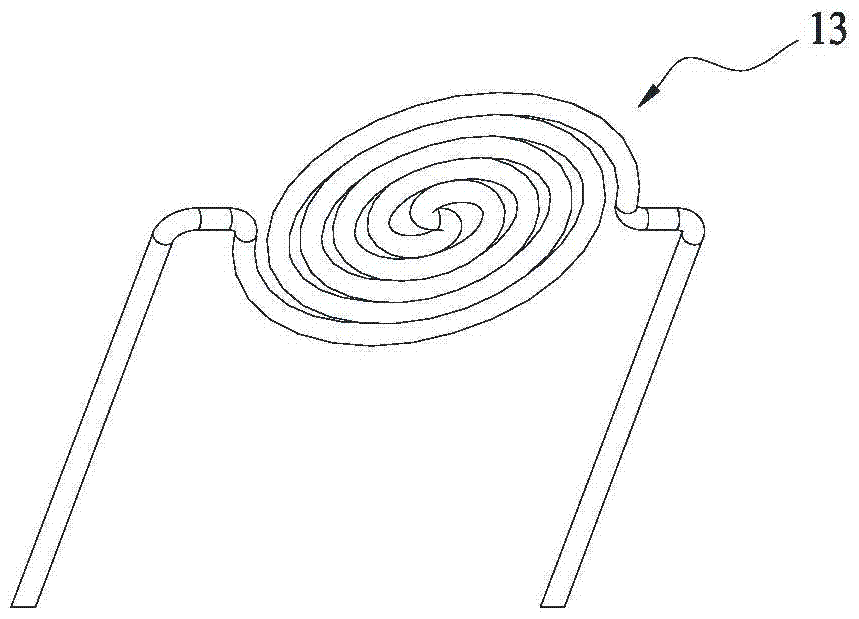

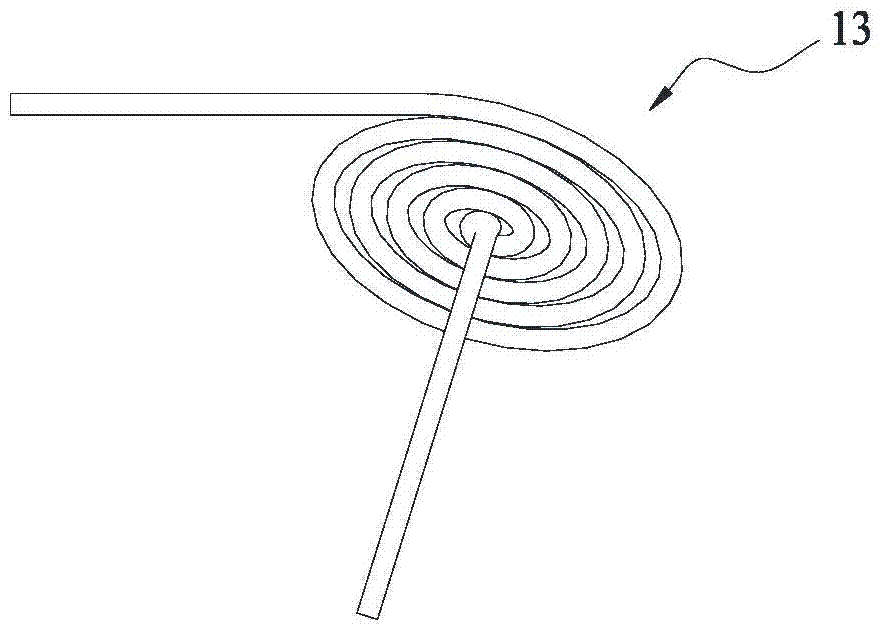

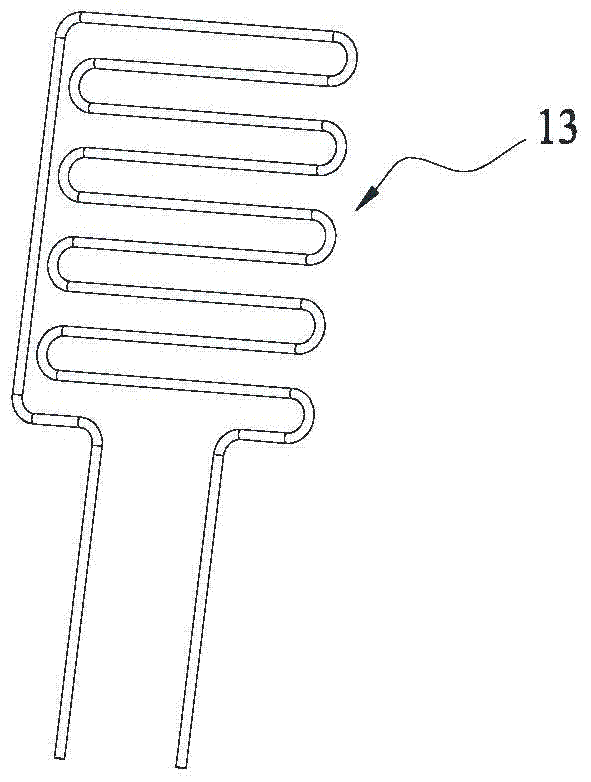

[0053] Such as Figure 5-7 An electronic cigarette vaporizer shown includes a heating component 10 and a conductive component 20. The heating component 10 includes a base 11, a fixing seat 12, a heating wire 13, a liquid storage medium 14 and a liquid conducting medium 15. The base 11 has a vertical through The fixing hole 111 of the base 11 and the first liquid guide hole 112 passing through the base 11 in the transverse direction, the first liquid guide hole 112 communicates with the fixing hole 111, the conductive component 20 is connected to the lower end of the heating component 10; the fixing seat 12 is detachable Sealed and fixed in the fixing hole 111, the fixing seat 12 has an airflow channel 121 vertically penetrating the fixing seat 12, the airflow channel 121 is connected to the two ends of the fixing hole 111, and the fixing seat 12 on the side of the airflow channel 121 A fixed port 122 is opened, and the fixed port 122 is separated from the air flow passage 121 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com