Combined type sieve tube

A combined, screen tube technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of low pressure bearing capacity, easy crushing of the filter body, and no wear resistance, so as to achieve pressure bearing capacity. High strength, lower oil production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

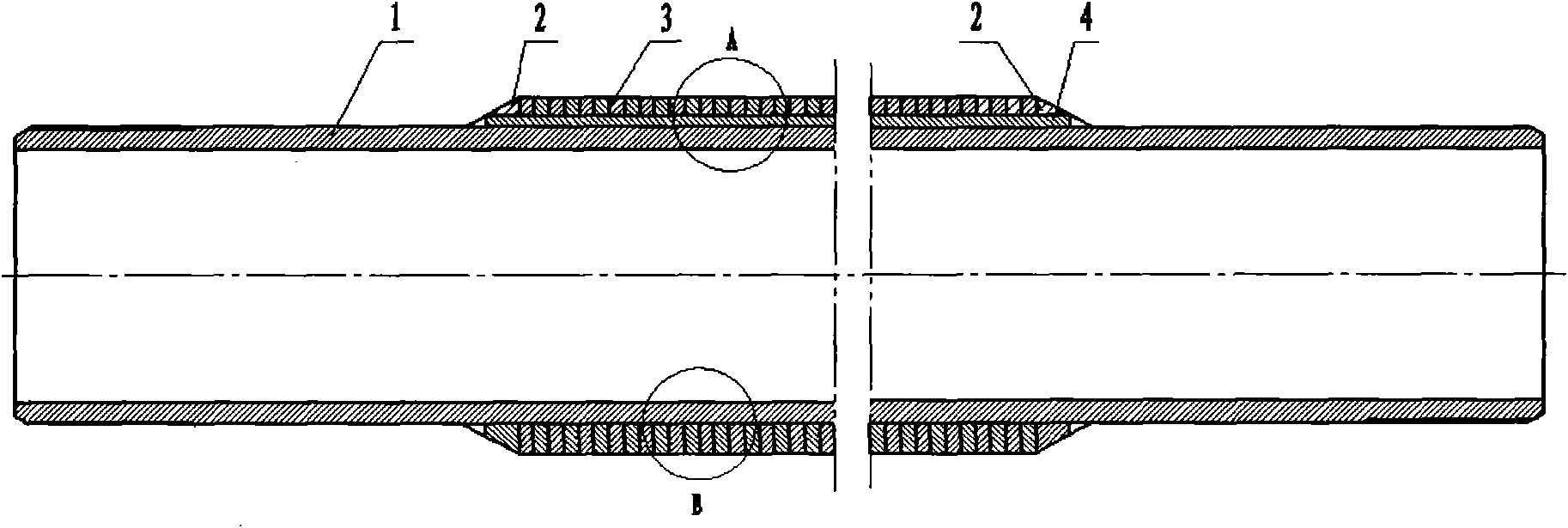

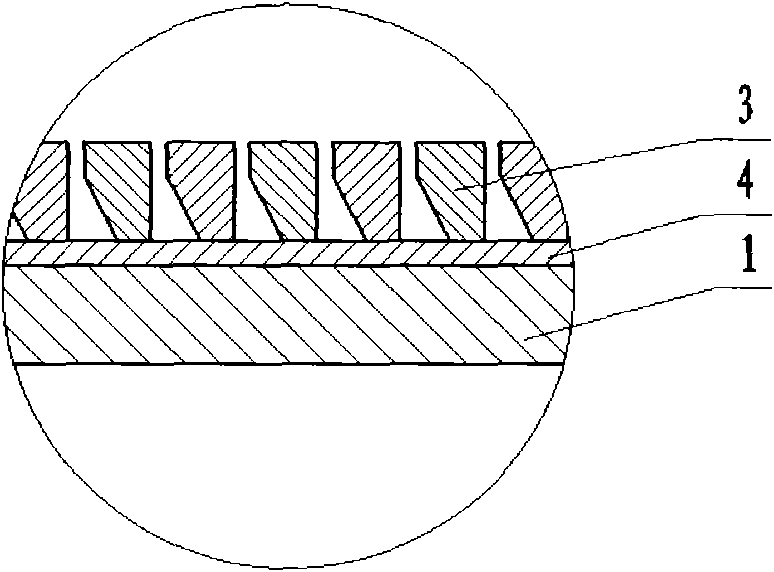

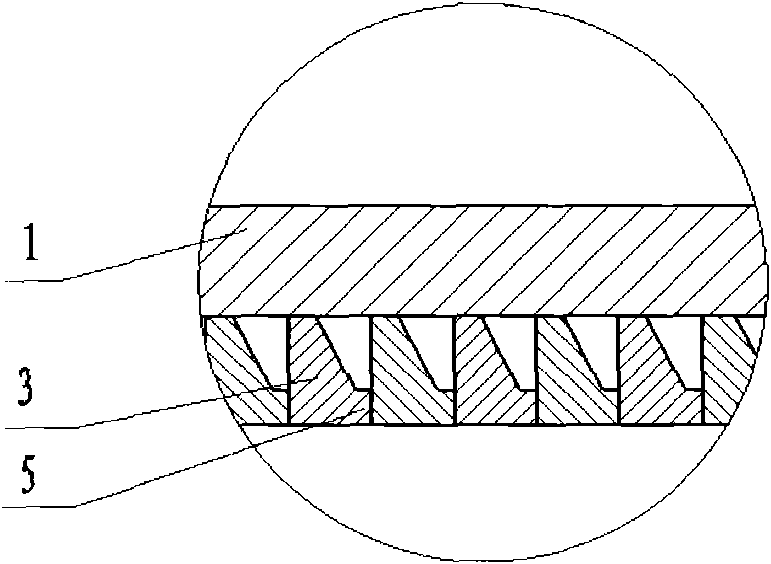

[0017] The sieve sheet in the combined screen tube of the present invention is circular, with an outer diameter of 70-196 mm; an inner diameter of a straight hole of 60-178 mm, which is the same as the outer diameter of the base pipe; a thickness of 5-10 mm; and an angle of a conical hole of 25-45° . The width of the end surface on one side of the conical hole is 1.5-3.0mm, and there are bosses evenly distributed on the end surface. The number of bosses is at least 3, usually 4-8, the height of the bosses is 0.3-1mm, and the width is 2-3mm. The number of axial liquid flow grooves on the inner hole wall of the sieve sheet is 4 to 8, and the radius of the arc axial liquid flow grooves is 5 to 10mm. During manufacture, try to avoid that the bosses, axial liquid flow grooves and key grooves on the sieve are located in the same radial direction. The inner and outer diameters of the gland are the same as the inner and outer diameters of the sieve.

[0018] The sieve in the combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com