Method and system for preparing brine by using inferior raw material salt

A raw material, inferior technology, applied in alkali metal halide purification, alkali metal chloride and other directions, can solve the problems of restricting the sustainable development of Jilantai Salt Lake, high price, low sodium chloride content, etc., to maintain sustainability The effect of developing, increasing the sodium chloride content and prolonging the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

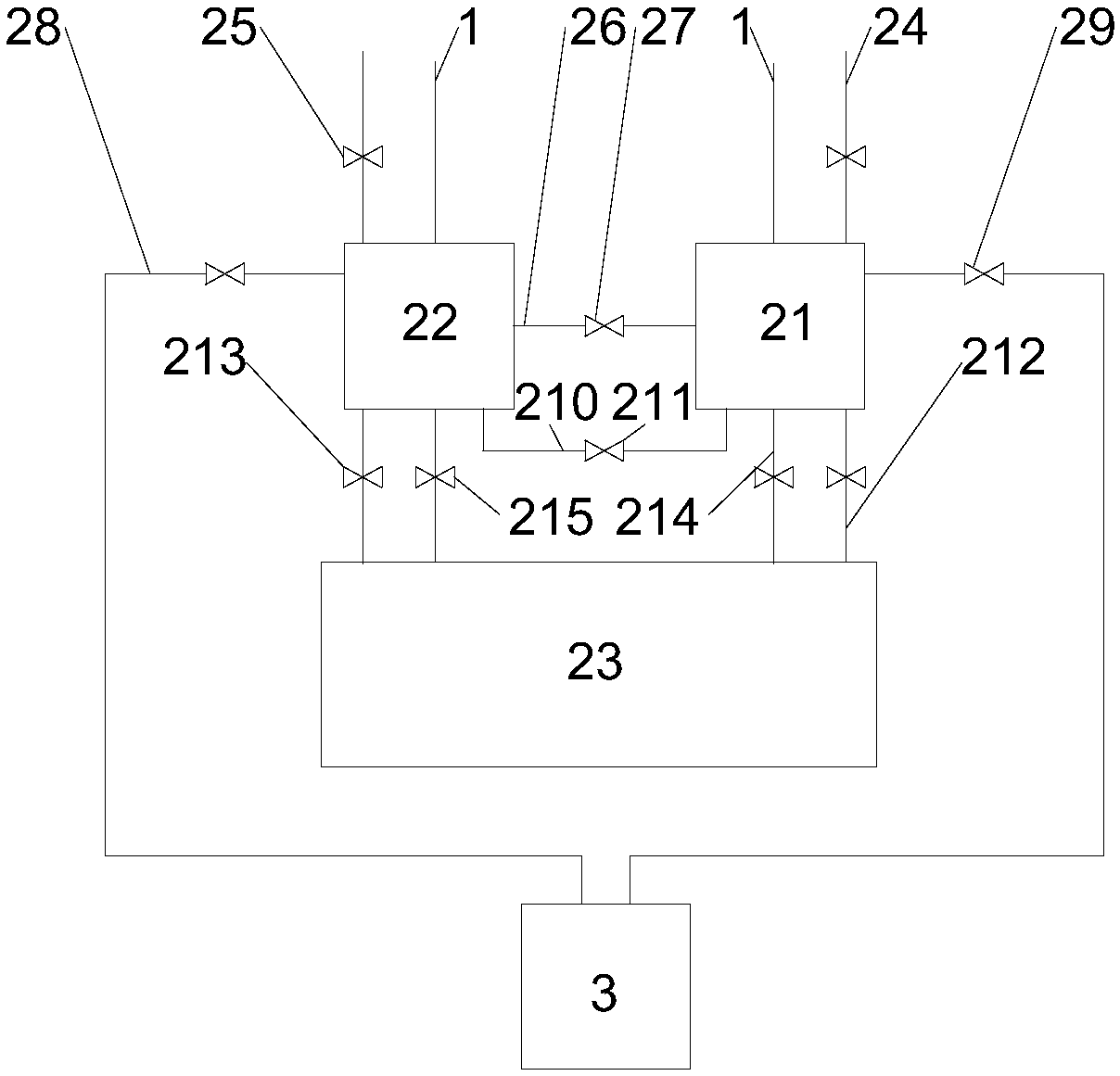

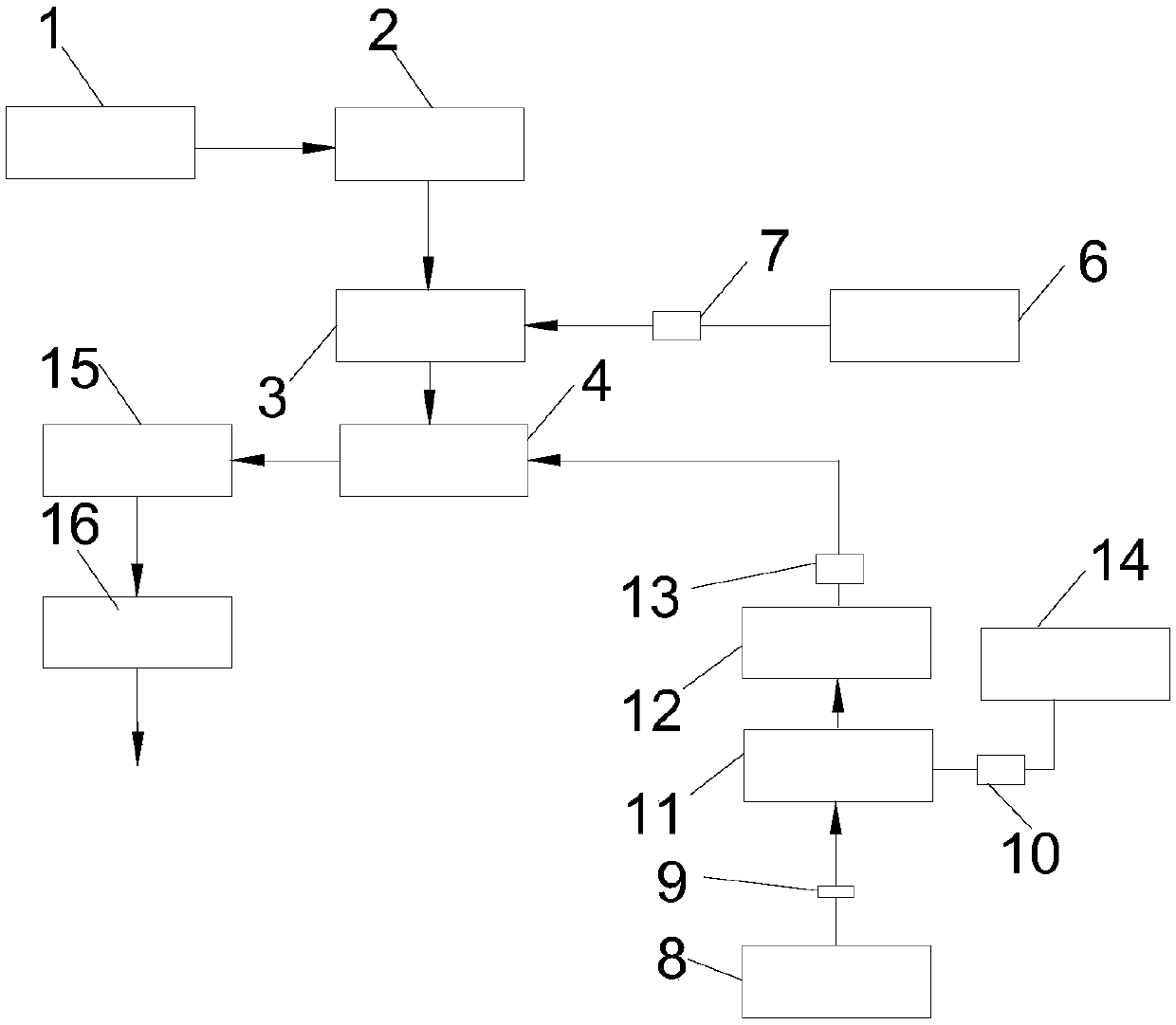

[0030] Such as figure 1 , 2As shown, the system for preparing brine by using inferior raw material salt includes a raw salt conveyor belt 1, a salt conversion system 2, an impurity removal system and a solution configuration system;

[0031] The salt chemical system 2 includes a first salt chemical tank 21 and a second salt chemical tank 22. The inferior raw material salt is conveyed through the raw salt conveyor belt 1, and the discharge end of the raw salt conveyor belt 1 is connected with the first salt chemical tank of the salt chemical system 2 respectively. 21. The feed port of the second chemical salt tank 22 is connected, the first salt chemical tank 21 and the first salt chemical tank 21 are connected to the tap water pipeline through the tap water pipe 24, and the tap water valve 25 is provided on the tap water pipe 24. In this embodiment, tap water is used for the initial salinization of inferior raw material salt, that is, the tap water valve 25 is opened, and tap...

Embodiment 2

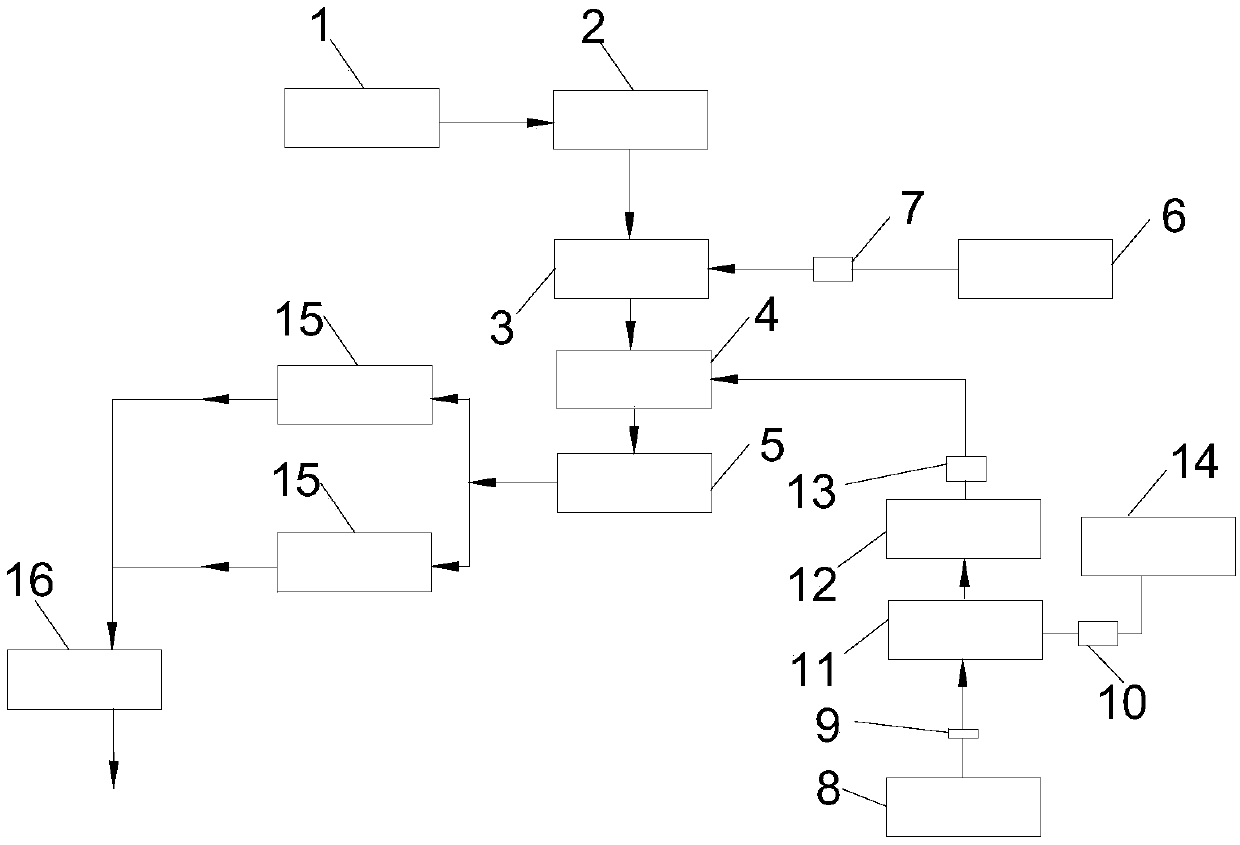

[0035] Such as figure 1 , 3 As shown, the system for preparing brine by using inferior raw material salt includes a raw salt conveyor belt 1, a salt conversion system 2, an impurity removal system and a solution configuration system;

[0036] The salt chemical system 2 includes a first salt chemical tank 21 and a second salt chemical tank 22. The inferior raw material salt is conveyed through the raw salt conveyor belt 1, and the discharge end of the raw salt conveyor belt 1 is connected with the first salt chemical tank of the salt chemical system 2 respectively. 21. The feed port of the second chemical salt tank 22 is connected, the first salt chemical tank 21 and the first salt chemical tank 21 are connected to the water pipe 24 through the tap water pipe 24, and the tap water valve 25 is provided on the tap water pipe 24. When using this embodiment for the first time, tap water is used for the primary desalination of inferior raw material salt, that is, the tap water valv...

Embodiment 3

[0040] Utilize the method that embodiment 2 is carried out and utilize inferior raw material salt to prepare bittern, it may further comprise the steps:

[0041] (1) Chemical salt: Dissolve the inferior raw material salt with dissolved salt, which is tap water or low-salt solution. When performing (1) chemical salt for the first time, the dissolved salt water is tap water; It is a low-salt liquid; when the Baume degree of the solution is 23°Bé, solid-liquid separation is carried out, the liquid obtained is the liquid to be removed, and the solid obtained is salt slag; adding slag-dissolving water to the salt slag and continuing to dissolve, the slag-dissolving water is Tap water or ammonia distillation wastewater; when the Baume degree of the solution is 10°Bé, low-salt slurry is obtained, and the low-salt slurry is subjected to solid-liquid separation to obtain low-salt liquid and waste residue. The sodium chloride content of the waste residue is 6%, and the waste residue Dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com