A kind of preparation method of 6-chloro-2,4-dinitroaniline

A technology of dinitroaniline and sodium chlorate, applied in the chemical industry, can solve the problems of low cleaning efficiency, high water consumption, time-consuming and labor-intensive, etc., and achieve the effects of reducing waste water discharge, fast cleaning method, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

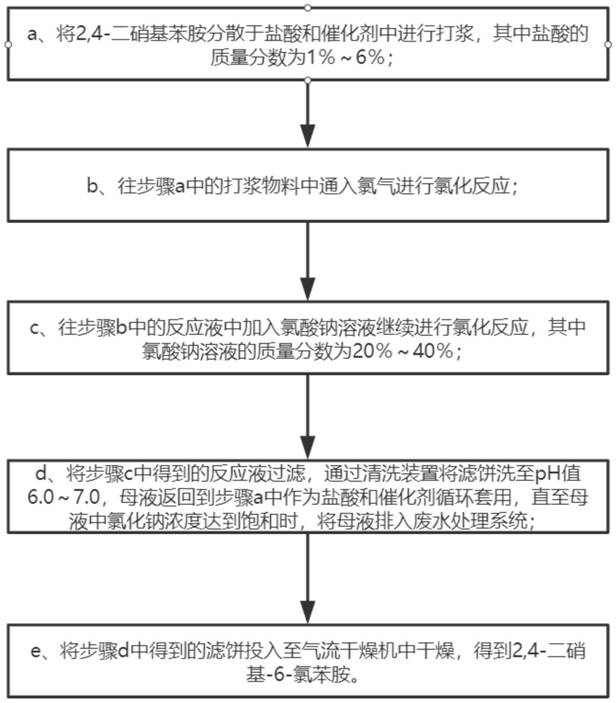

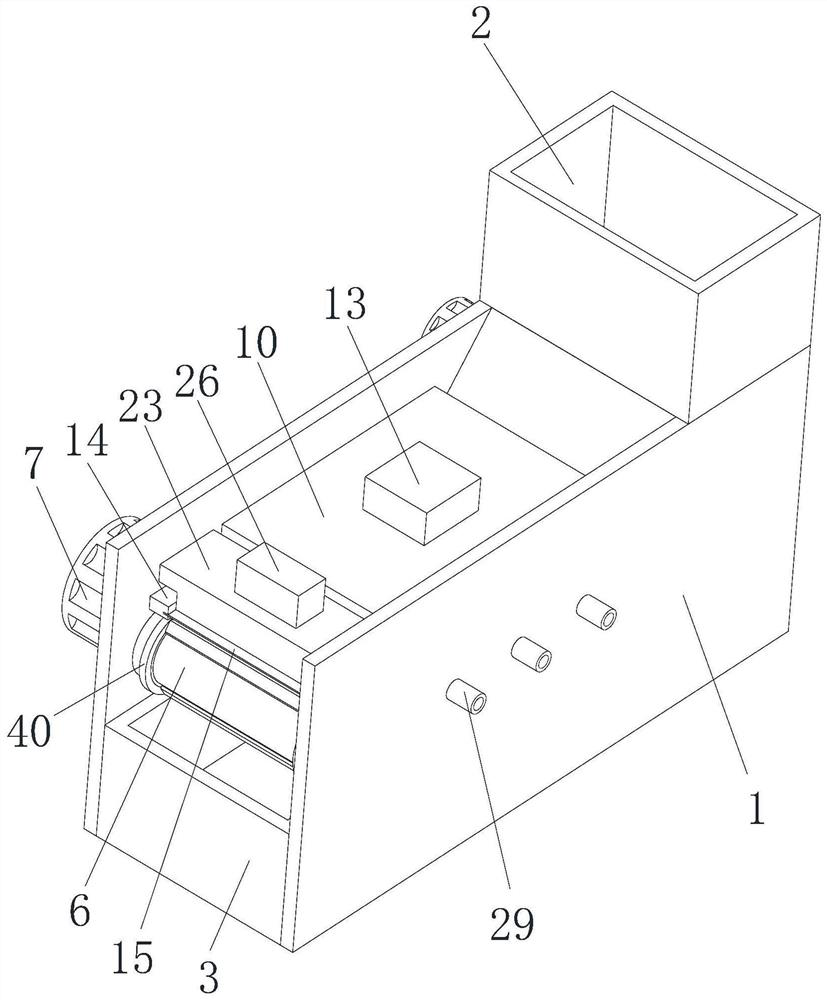

[0037] Such as Figure 1-7Shown, a kind of 6-chloro-2,4-dinitroaniline preparation method comprises the following steps:

[0038] a. Dispersing 2,4-dinitroaniline in hydrochloric acid and catalyst for beating, wherein the mass fraction of hydrochloric acid is 1%;

[0039] B, feed chlorine into the beating material in step a and carry out chlorination reaction;

[0040] C, add sodium chlorate solution in the reaction solution in step b and continue chlorination reaction, wherein the massfraction of sodium chlorate solution is 20%;

[0041] d, filter the reaction solution obtained in step c, wash the filter cake to a pH value of 6.0 to 7.0 through a cleaning device, and return the mother liquor to step a for recycling as hydrochloric acid and catalyst until the concentration of sodium chloride in the mother liquor reaches saturation. Discharge the mother liquor into the wastewater treatment system;

[0042] e, putting the filter cake obtained in step d into an airflow dryer f...

Embodiment 2

[0066] Such as figure 1 Shown, a kind of 6-chloro-2,4-dinitroaniline preparation method comprises the following steps:

[0067] a. Dispersing 2,4-dinitroaniline in hydrochloric acid and catalyst for beating, wherein the mass fraction of hydrochloric acid is 6%;

[0068] B, feed chlorine into the beating material in step a and carry out chlorination reaction;

[0069] C, add sodium chlorate solution in the reaction solution in step b and continue chlorination reaction, wherein the massfraction of sodium chlorate solution is 40%;

[0070] d, filter the reaction solution obtained in step c, wash the filter cake to a pH value of 6.0 to 7.0 through a cleaning device, and return the mother liquor to step a for recycling as hydrochloric acid and catalyst until the concentration of sodium chloride in the mother liquor reaches saturation. Discharge the mother liquor into the wastewater treatment system;

[0071] e. Put the filter cake obtained in step d into an air dryer to dry to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com