A kind of recovery and utilization method of carnallite liquid in the production of potassium chloride

A carnallite, potassium chloride technology, applied in the directions of alkali metal chloride, bromine/hydrogen bromide, magnesium sulfate, etc., can solve the problem of affecting the quality of carnallite products, affecting the production of potassium chloride products, carnallite NaCl The problems such as the increase of the content, to achieve the effect of easy industrialization, reduction of the content, and low degree of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

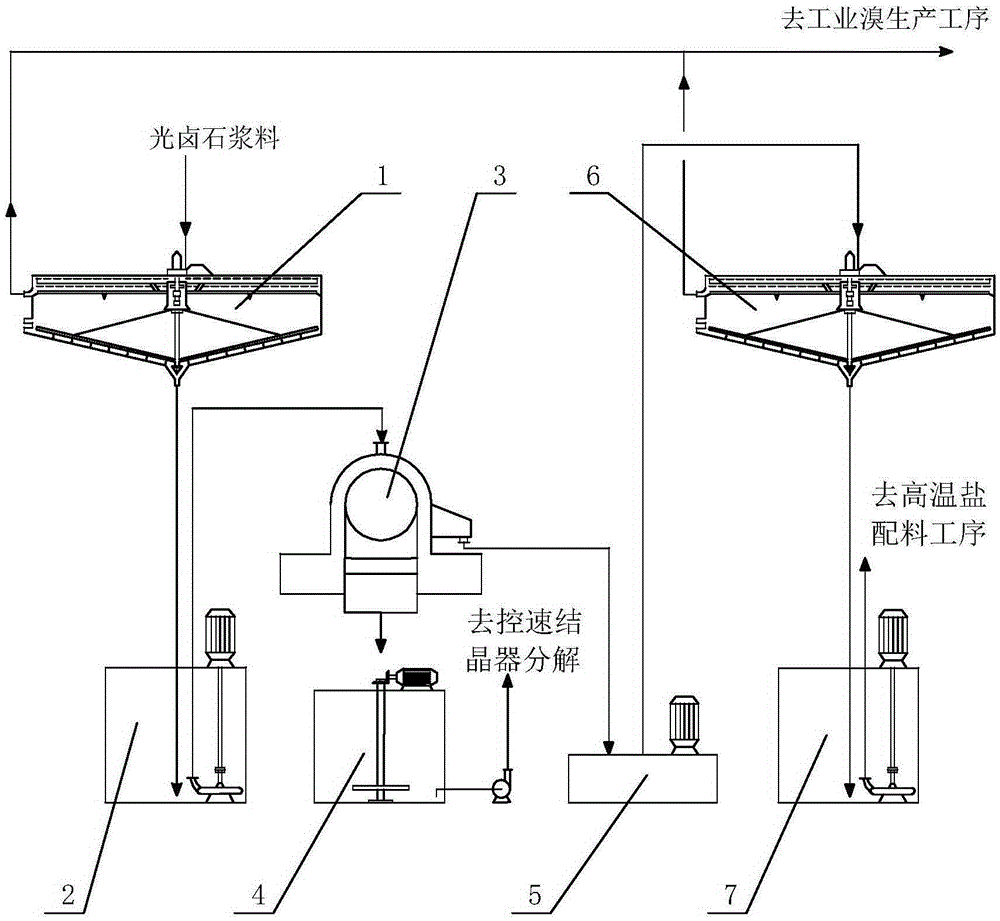

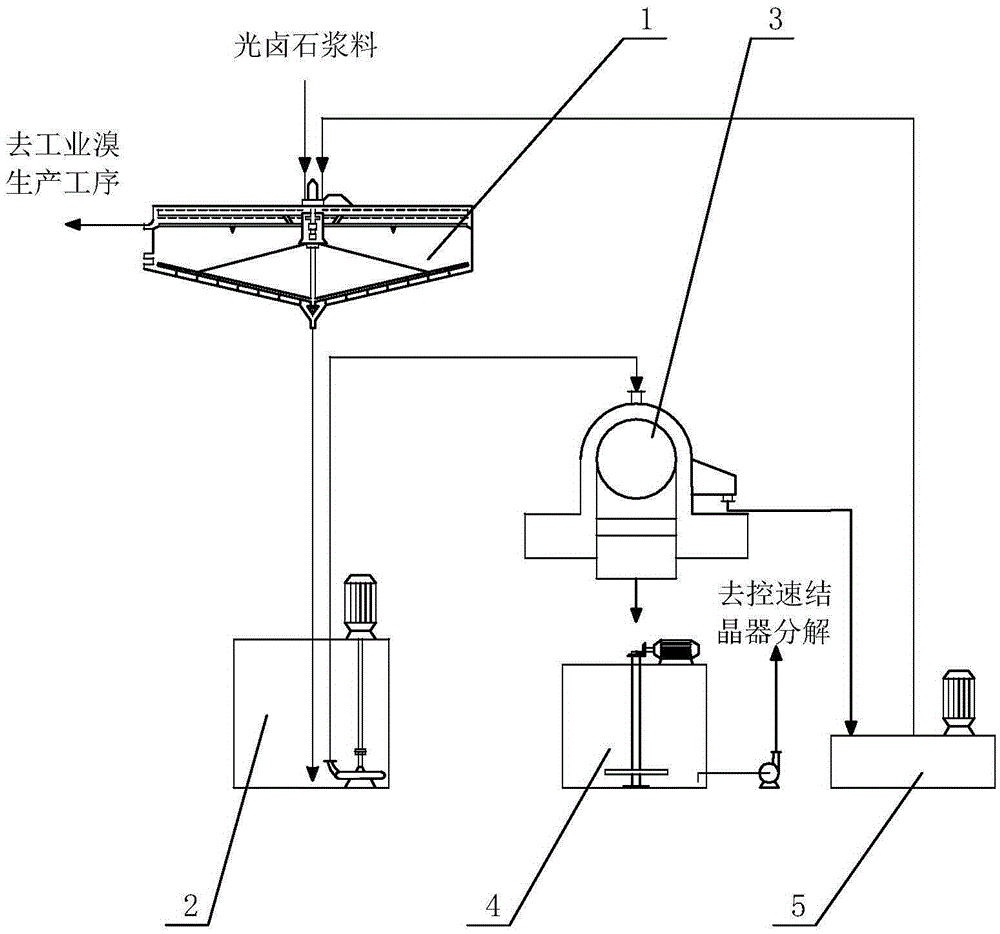

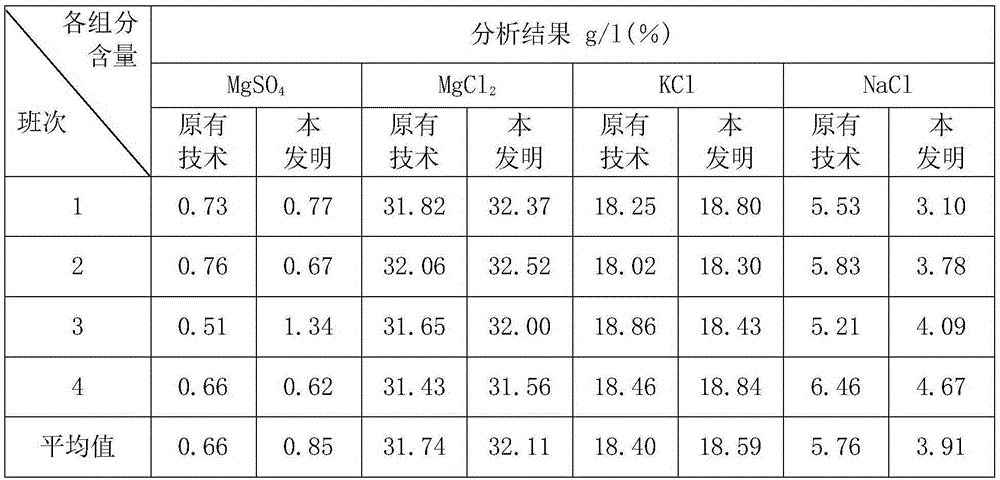

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0020] A kind of recycling method of liquid after carnallite throws off in the production of potassium chloride, specifically operates according to the following steps:

[0021] After the bittern is mixed with bittern, evaporated, heat-preserved and settled, the overflow clarified liquid enters the cooling crystallization process to obtain carnallite slurry, which is transported to the carnallite settler for settlement. The carnallite obtained from the carnallite settler is buffered by the carnallite buffer tank and sent to the centrifuge for separation. The separated solid enters the carnallite tank for stirring and washing, then is sent to the speed-controlled crystallizer for decomposition, and then enters the washing, Dehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com