Method for treating reverse osmosis concentrated water

A reverse osmosis concentrated water and treatment method technology, applied in the field of industrial wastewater treatment, can solve problems such as complex process, high operating cost, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

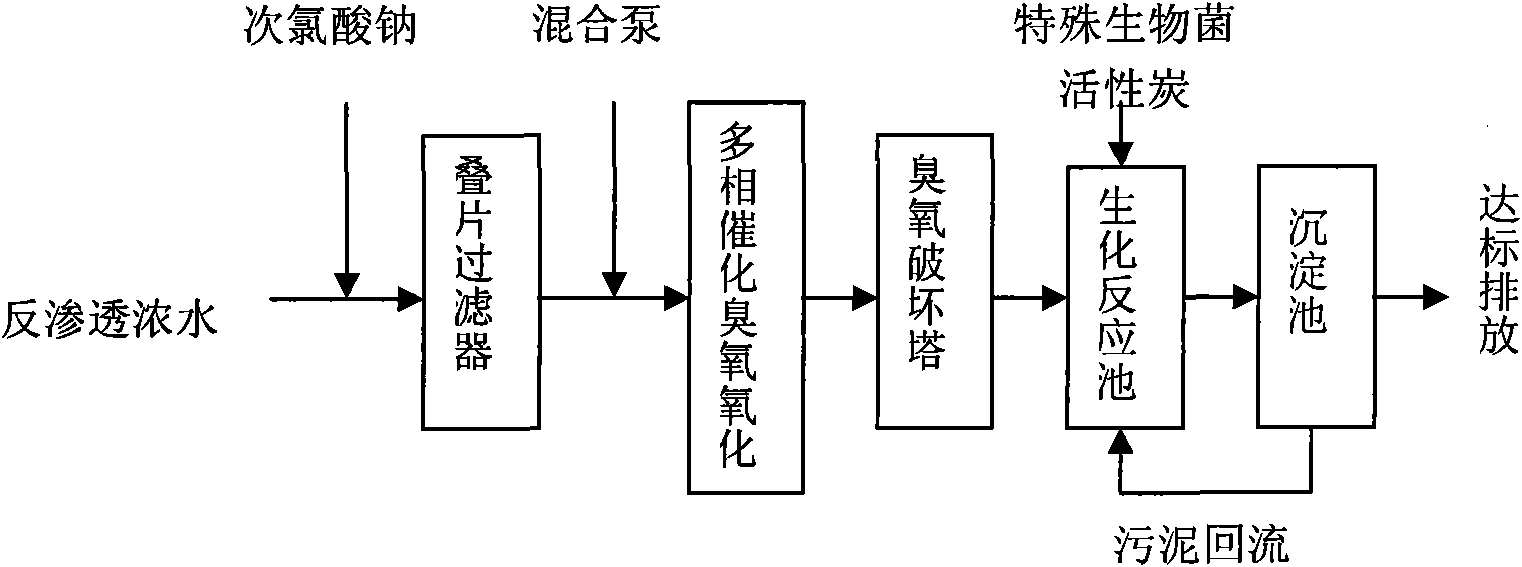

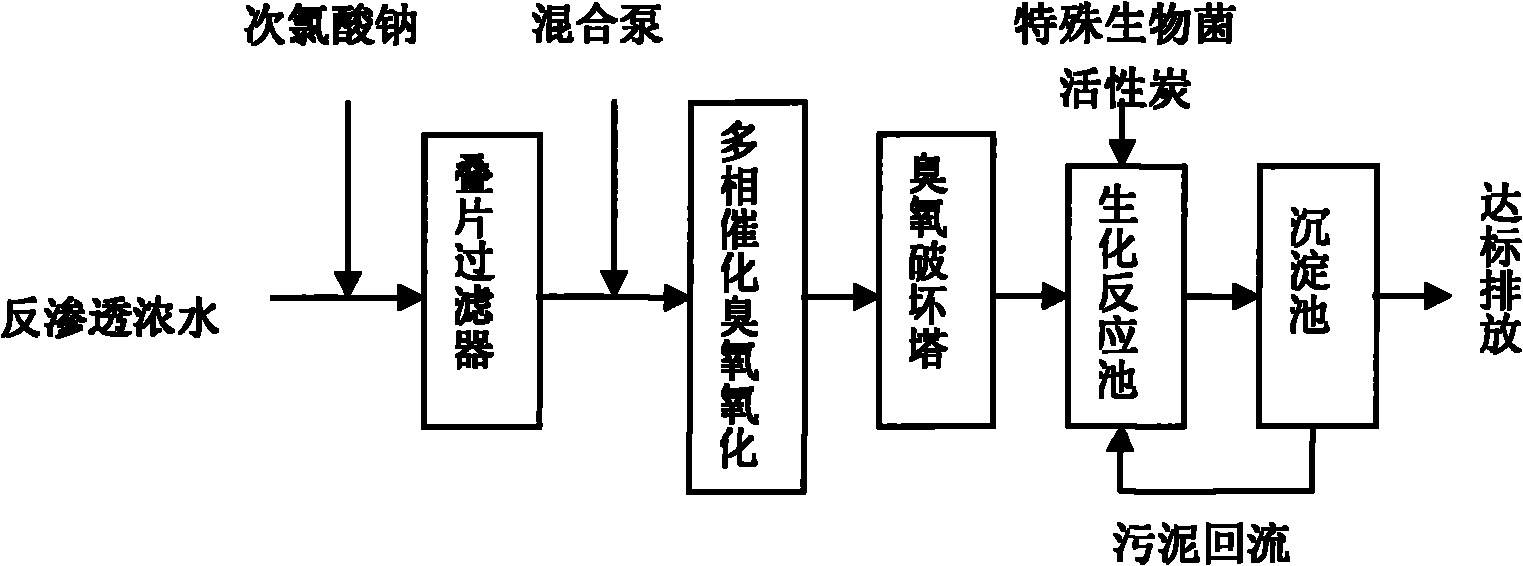

Method used

Image

Examples

Embodiment 1

[0022] Refining sewage of a petrochemical plant, including: crude oil tanks and oil-water separation tanks of various devices or cut-off water of product oil tanks, machine pump cooling water, cold coke water cut-off water, tank washing vehicle drainage and pre-drainage in the production area. After more than 80 hours of two-stage biochemical treatment, the sewage has a COD of 40mg / L, which can reach the discharge standard. The petrochemical plant passes the waste water through fiber filtration + activated carbon filtration + integrated treatment, blends part of the fresh water, and then uses ultrafiltration + reverse osmosis to reuse 75%. Treat and reuse 60%, the COD in the remaining concentrated water is 100mg / L, and the organic pollutants are mainly: naphthenic acid and polydimethylsiloxane, BOD 5 Zero, extremely poor biodegradability. The waste water is treated as follows:

[0023] 1) First, add 3 mg / L of sodium hypochlorite to the waste water, filter through a laminated...

Embodiment 2

[0029] The refinery sewage of a petrochemical plant is composed of crude oil tanks and oil-water separation tanks of various devices or cut water of finished oil tanks, machine pump cooling water, cold coke water cut water, tank washing vehicle drainage and pre-drainage in the production area. After the sewage is treated by three-stage biochemical treatment, the COD is 40-50 mg / L. The petrochemical plant reuses 75% of the wastewater through quicksand filter + fiber ball filtration + ultrafiltration + reverse osmosis, and the remaining 25% of the concentrated water is COD 170mg / L, the main components of organic pollutants are naphthenic acid, BOD 5 2.2mg / L, BOD 5 / COD is 0.01, and the biodegradability is poor. The waste water is treated as follows:

[0030] 1) First, add 3 mg / L of sodium hypochlorite to the waste water, filter through a laminated filter with a filtration accuracy of 100 μm, and the turbidity of the effluent cannot be detected;

[0031] 2) The effluent of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com