Heat-resisting alloy with high yield ratio, high toughness and long-run elasticity stability

A technology of elastic stability and heat-resistant alloys, applied in the field of alloys, can solve the problems of strength, toughness, elastic failure, aircraft machine failure, etc., and achieve the effect of improving the effect of grain boundary strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

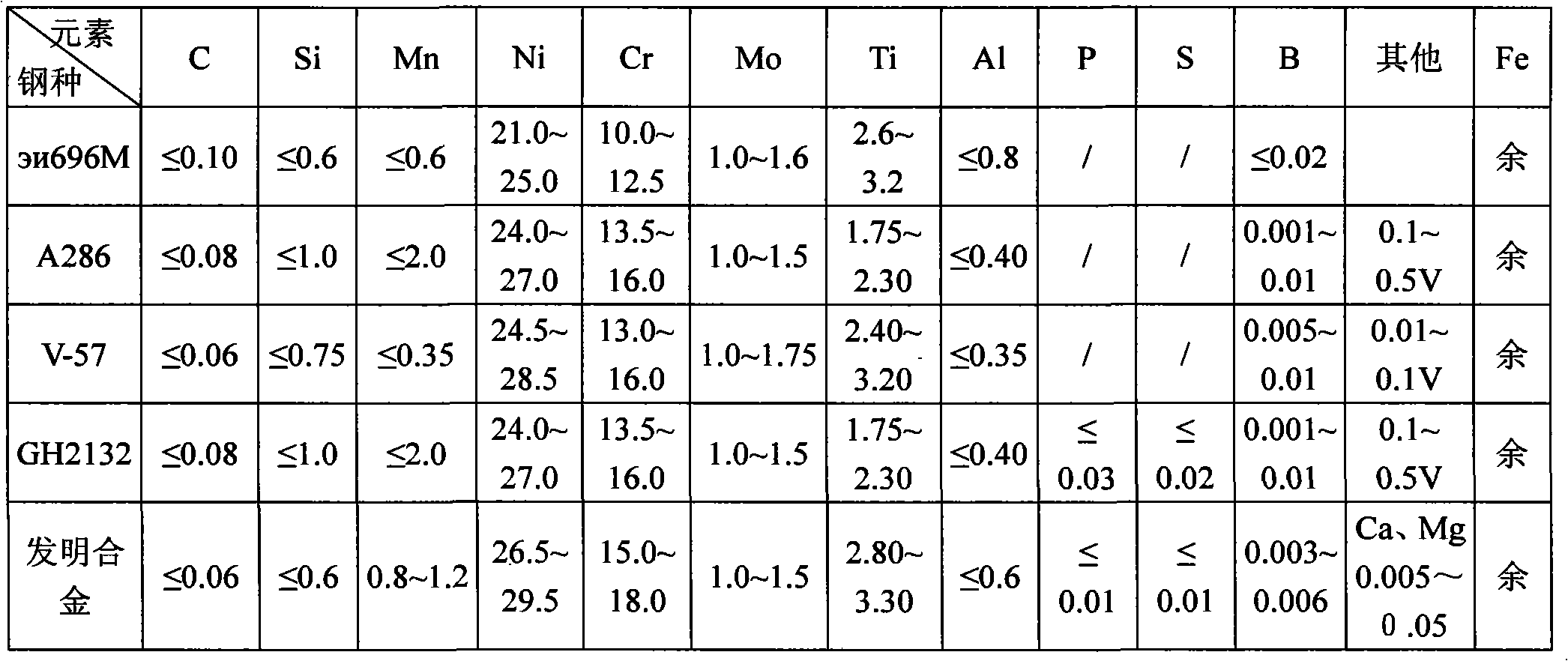

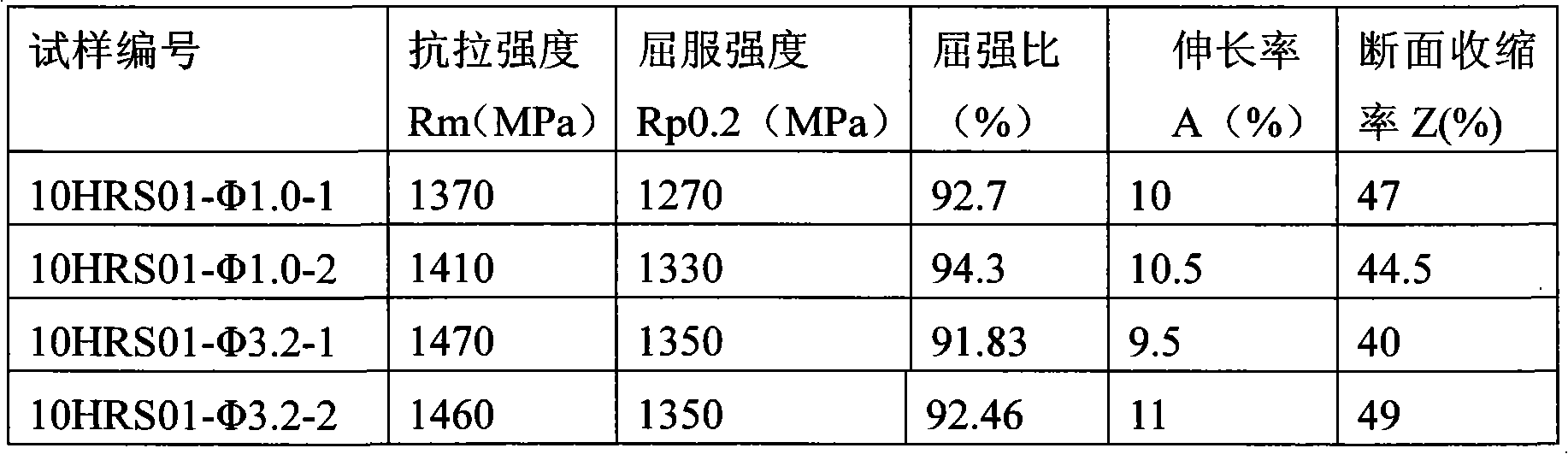

[0053] A heat-resistant alloy with high yield ratio, high toughness, long-term elastic stability, characterized in that it consists of the following components in weight percentage: C 0.034, Si 0.4, Mn 1.04, Ni 27.5, Cr 16, Mo 1.4, Ti 3.05, Al 0.51 B 0.0033, Ca0.01, Mg0.01, the balance is Fe. The alloy ingots produced are hot-processed and cold-processed into wires, strips, rods, and pipes, which are used in various types of high-strength, high-toughness, long-term elastic stability, high-temperature resistance, and elasticity required by aviation, petrochemical, metallurgy, and electromechanical industries. element.

Embodiment 2

[0055] A heat-resistant alloy with high yield ratio, high toughness, long-term elastic stability, characterized in that it consists of the following components in weight percentage: C 0.024, Si 0.35, Mn 1.10, Ni 28, Cr 16.5, Mo 1.3, Ti 2.8, Al 0.4B 0.0033, Ca0.005, Mg0.005, the balance is Fe. The alloy ingots obtained by vacuum smelting and electroslag remelting double process are hot-processed and cold-processed into bars and forgings, which are used in high-strength heat-resistant rotors and heat-resistant forgings for power stations.

Embodiment 3

[0057] A heat-resistant alloy with high yield ratio, high toughness, long-term elastic stability, characterized in that it is composed of the following components in weight percentage: C 0.040, Si 0.35, Mn 1.10, Ni 28, Cr 16.5, Mo 1.3, Ti 2.8, Al 0.4 B 0.0033, Ca0.05, Mg0.05, the balance is Fe. The alloy is smelted by vacuum induction, and then the alloy ingot is obtained through the dual process of electroslag remelting. The hot working temperature of the alloy is 1160°C to 850°C. After thermal processing and cold processing, it is made into bars and forgings, which are used in high-strength heat-resistant rotors and heat-resistant forgings for power stations. During the cold working process, the alloy must be solution treated in time to eliminate cold work hardening. The solution treatment system is a holding temperature of 1080 ° C, a holding time of 30 to 60 minutes, and water quenching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com