Cold rolling apparatus for electromagnetic steel sheet and rolling method

An electromagnetic steel plate and equipment technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of camera image processing that cannot be processed correctly, high crack sensitivity, and difficulty in ensuring safe access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

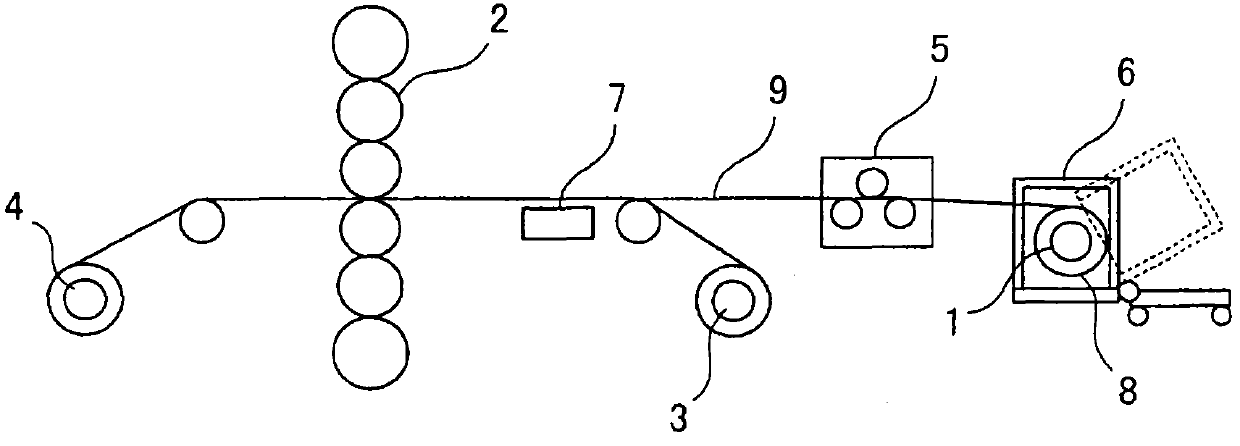

[0048] figure 1 A cold rolling facility for electrical steel sheets according to Example 1 of the present invention is shown.

[0049] Such as figure 1 As shown, the tension rolls 3, 4 are arranged before and after the rolling mill 2 that cold-rolls the electrical steel sheet (hereinafter referred to as the steel plate) 9, and the tension rolls 3, 4 can carry out the coiling and unwinding of the coil, thereby Reversible rolling can be carried out, and a pay-off reel 1 for discharging the raw plate coil and a straightening machine 5 for straightening the electromagnetic steel sheet 9 with the curvature of the coil to be flat are arranged in front of the tension roller 3, and a spare A heating device 6 and a heating device 7 are arranged between the rolling mill 2 and the tension roll 3 .

[0050] The pre-heating device 6 is a box-type that surrounds the drum of the pay-off reel 1 and the original sheet coil 8. As shown by the dotted line in the figure, it is a structure that ...

Embodiment 2

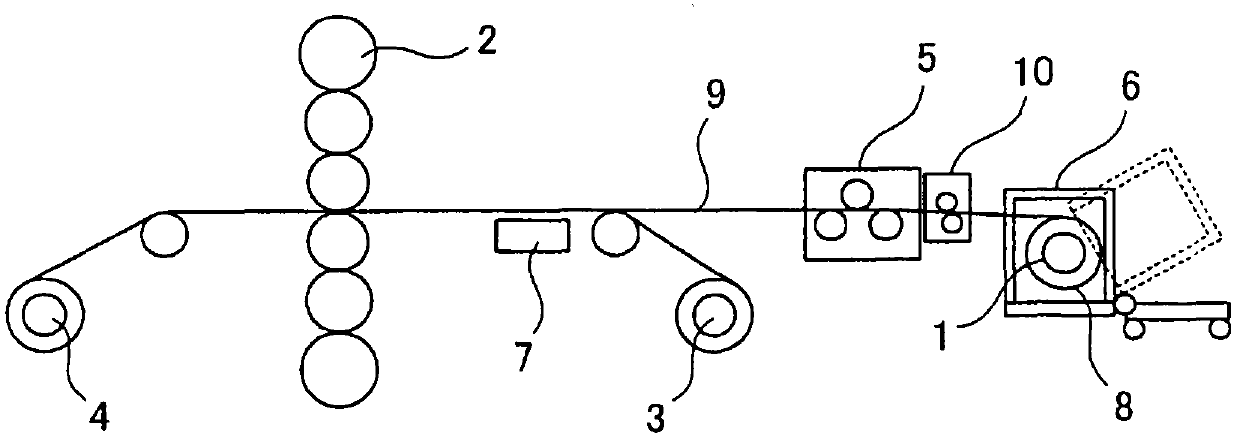

[0082] figure 2 A cold rolling facility for electrical steel sheets according to Example 2 of the present invention is shown.

[0083] This embodiment relates to the rolling facility in which the preliminary heating device 6 of the pay-off reel 1 is equipped with a warm liquid spray (spray).

[0084] That is, the pre-heating device 6 is a box-shaped enclosure that surrounds the drum of the pay-off reel 1 and the original sheet coil 8, and the pre-heating device 6 of the box-type has a warm liquid sprayer (not shown), and the warm liquid sprayer is sent into the The cooling liquid that cools the rolls during rolling is a warm liquid that is further heated.

[0085] In addition, a dewatering device 10 is disposed between the pay-off reel 1 and the straightening machine 5 in order to discharge warm liquid adhering to the surface of the steel sheet.

[0086] The other structures are the same as those in the first embodiment, and the same structures are given the same symbols, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com