Ultrahigh-strength stress relaxation-resistant conductive elastic copper alloy and preparation method thereof

A stress relaxation resistant and elastic copper alloy technology, applied in conductive materials, conductive materials, metal rolling, etc., can solve the problems of increased hardness and brittleness of copper alloys, difficulty in meeting use requirements, and failure of elastic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing the ultra-high-strength stress-relaxation-resistant conductive elastic copper alloy described in the above technical solution, comprising the following steps:

[0037] (1) casting the alloy raw material after smelting to obtain a copper alloy ingot;

[0038] (2) performing hot rolling, solution treatment and primary aging treatment on the copper alloy ingot obtained in the step (1) successively to obtain a pre-deformed copper alloy;

[0039] (3) performing primary cold rolling and secondary aging treatment on the pre-deformed copper alloy obtained in the step (2) to obtain a re-deformed copper alloy; the total deformation of the primary cold rolling is 70% to 90%;

[0040] (4) The re-deformed copper alloy obtained in the step (3) is subjected to secondary cold rolling and annealing treatment successively to obtain an ultra-high-strength stress relaxation-resistant conductive elastic copper alloy; the total defor...

Embodiment 1

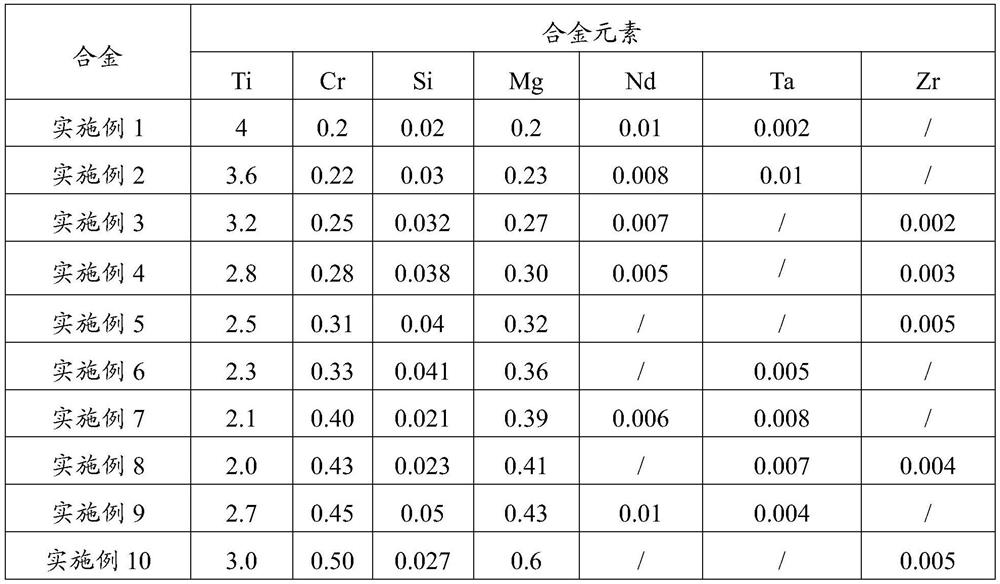

[0067] The composition of the ultra-high-strength stress-relaxation-resistant conductive elastic copper alloy provided in this example is shown in Example 1 of Table 1. The specific preparation method is as follows:

[0068] 1. Melting: Add electrolytic copper, sponge titanium, copper-chromium master alloy, pure magnesium and copper-silicon master alloy into the vacuum induction furnace. Raise the temperature to 1300°C, after the melt is completely melted, stir evenly, control the casting temperature at 1250°C, keep it warm for 30 minutes, and then cast to obtain copper alloy ingots.

[0069] 2. Hot rolling: Place the above-mentioned copper alloy ingot in a walking box furnace for heating at a temperature of 900°C and a holding time of 4 hours, and then carry out hot rolling. The final rolling temperature is controlled at 750°C, followed by water cooling.

[0070] 3. Solution treatment: place the above hot-rolled alloy slab in a box furnace for heating, the solution treatment t...

Embodiment 2

[0077] The composition of the ultra-high-strength stress-relaxation-resistant conductive elastic copper alloy provided in this example is shown in Example 2 of Table 1. The specific preparation method is as follows:

[0078] 1. Melting: Add electrolytic copper, sponge titanium, copper-chromium master alloy, pure magnesium and copper-silicon master alloy into the vacuum induction furnace. Raise the temperature to 1200°C, and after the melt is completely melted, stir evenly, control the casting temperature at 1150°C, keep the temperature for 30 minutes, and then cast to obtain copper alloy ingots.

[0079] 2. Hot rolling: Place the above-mentioned copper alloy ingot in a stepping box furnace for heating at a temperature of 800°C and a holding time of 4 hours, and then perform hot rolling. The final rolling temperature is controlled at 650°C, followed by water cooling.

[0080] 3. Solution treatment: place the hot-rolled slab of the above alloy in a box furnace for heating, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com