Carrying utensil

A technology for mounters and ceramic capacitors, which is applied in the fields of capacitors, capacitor manufacturing, lighting and heating equipment, etc., can solve the problems of reduced lifespan of mounters, degraded characteristics, discoloration of ceramic capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

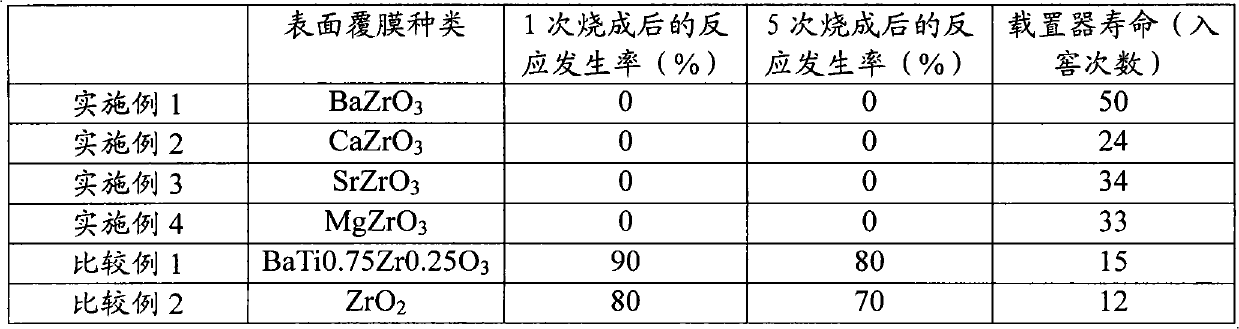

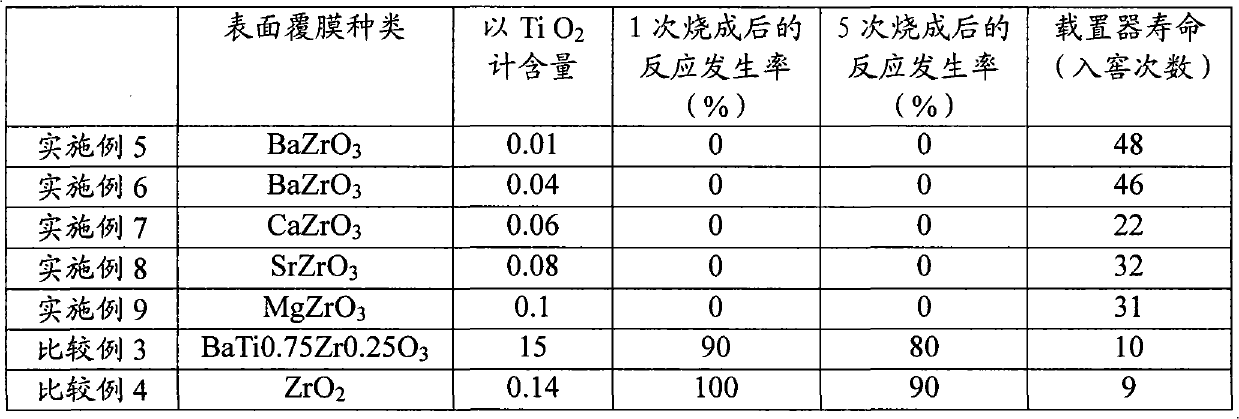

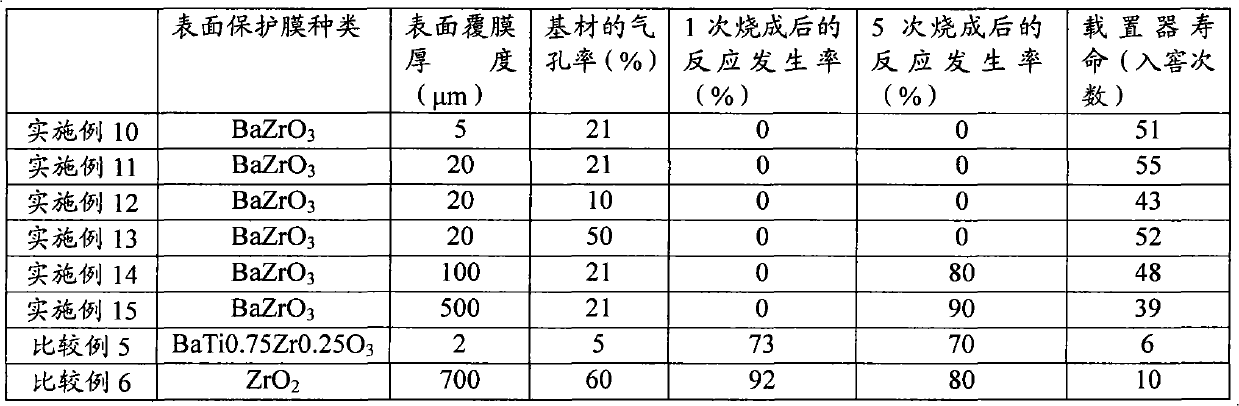

Examples

Embodiment

[0027] The present invention is further specifically described below through examples, but the present invention is not limited to the examples.

[0028] Alumina (Al 2 o 3 ) Alumina (Al 2 o 3 ) particles, 10% by mass of calcined alumina with a particle size of 0.5mm or less, 15% by mass of clay with a particle size of 10μm or less, and 25% by mass of andalusite with a particle size of 0.15mm or less, to prepare a mixed raw material. Next, 0.5 parts by mass of methyl cellulose as a binder and 3 parts by mass of water were added to 100 parts by mass of the obtained mixed raw material, followed by wheel mill kneading to obtain kneaded clay. Then, through a hydraulic press at 1t / cm 2 The kneaded clay was molded under a pressure of 150 mm×150 mm×4 mm, and the molded body was dried at 80° C. for 8 hours, and then fired at 1550° C. for 2 hours to produce an aluminum silicate substrate.

[0029] Next, use 8% by mass Y with a particle size of 100 to 200 μm 2 o 3Stabilize zircon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com