Production method for polyurethane enveloped controlled release fertilizer

A polyurethane and coating technology, which is applied in the field of polyurethane coated fertilizer preparation, can solve problems such as difficult automatic continuous operation, difficult control of reaction products, and interruption of operation, so as to shorten the probability and time of particle contact, shorten the distribution and reaction time , prevent moisture and bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Continuous Spray Coating Experiment of Reaction Material

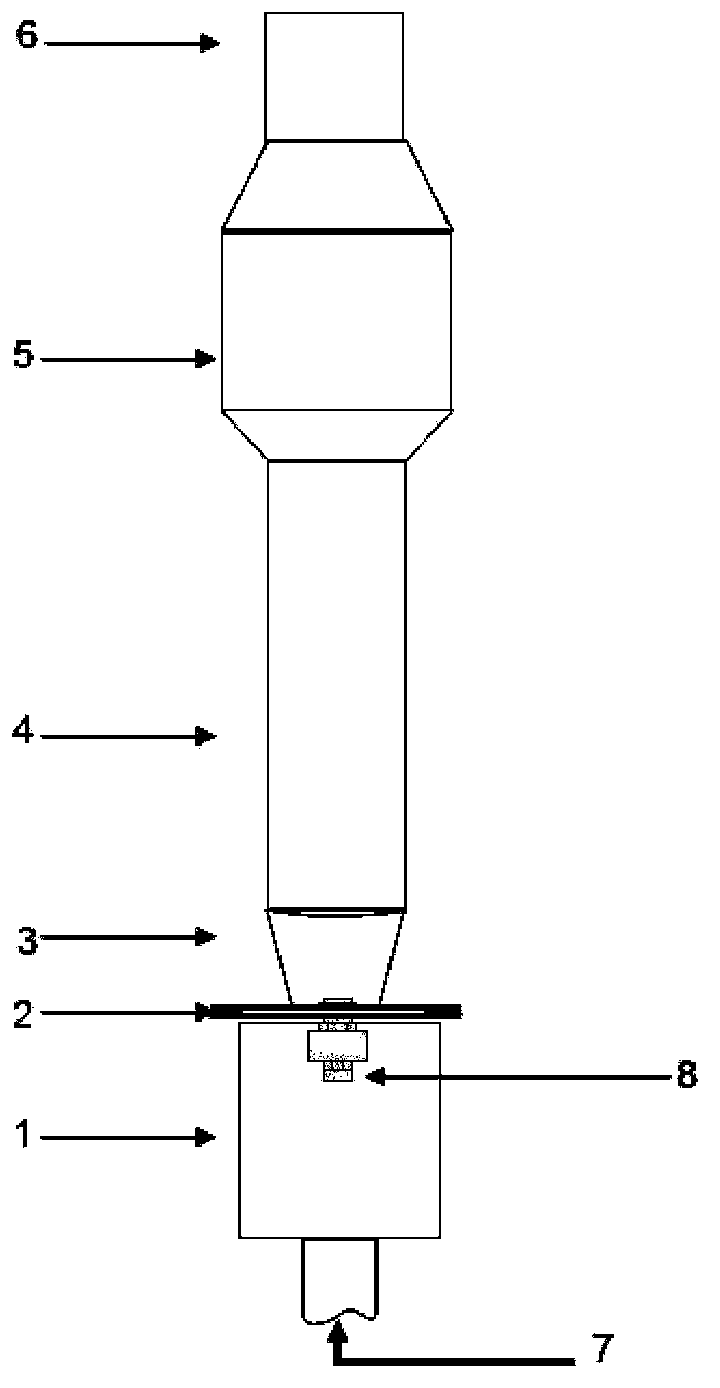

[0030] The fluidized bed cylindrical section used in this embodiment has a diameter of 150 mm, a length of 450 mm, a cone bottom diameter of 100 mm, and a cone angle of 65°.

[0031] The coating operation method and steps are as follows: First, adjust the coating parameters so that the fluidizing gas volume is 200m 3 / h, the compressed gas pressure is 0.2MPa, the gas volume is 200L / h, and the fluidized gas temperature is 85°C; secondly, weigh 1.5kg of large particle urea, add it from the exhaust port, and preheat for 2min; then, spray 10g of liquid Paraffin wax, pretreatment of urea, the treatment time is 2min; the fourth step, according to the molar ratio of isocyanate and polyol is 1.1:1, weigh about 12g of PAPI and 30g of castor oil (hydroxyl value 163), respectively according to 0.4 Add gPAPI / min and 1g castor oil / min into the nozzle with a peristaltic pump, and atomize the coating through the nozzl...

Embodiment 2

[0033] Embodiment 2 The influence of reaction material addition mode on coating operation

[0034] In order to verify the effect of rapid spray (mixed spray) coating operation after external mixing on coating operation, several different addition methods were used in the study, and the effects of addition methods on coating operation and fertilizer release performance were compared.

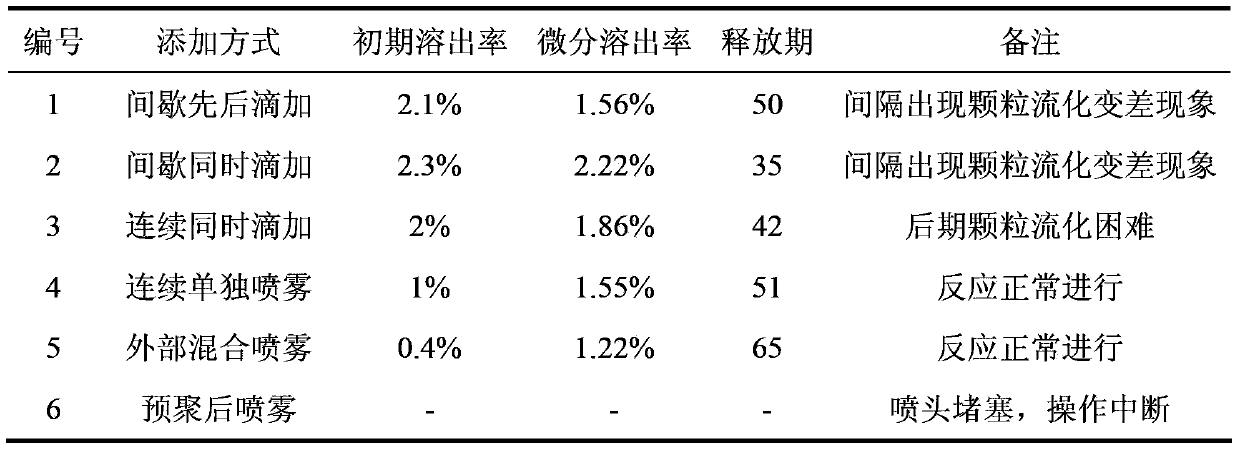

[0035] Addition methods of reaction materials include: intermittent successive dripping, intermittent simultaneous dripping, continuous simultaneous dripping, continuous simultaneous spraying, rapid spraying after external mixing (same as Example 1), and spraying after prepolymerization. Six treatment schemes, experimental conditions and control Parameter is the same as embodiment 1. The obtained experimental samples were tested for release performance by water immersion method. The experimental results are shown in Table 1.

[0036] Table 1 Effects of reaction material addition methods on coat...

Embodiment 3

[0039] Example 3 Effect of External Mixing Spray Treatment on the Reaction of Different Polyurethane Coatings

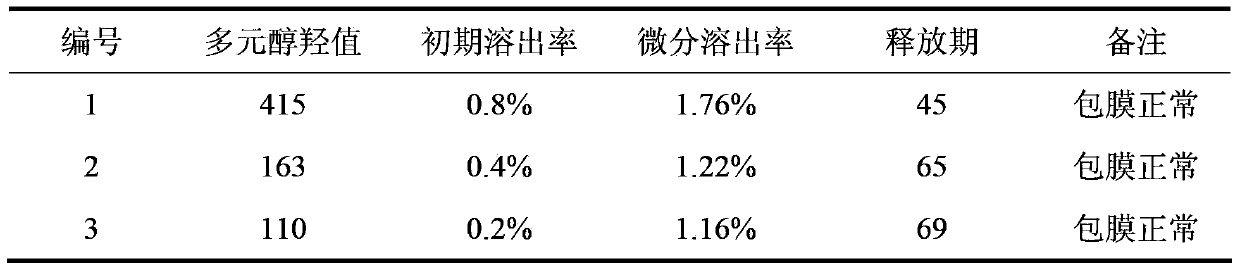

[0040] Using the same process conditions as in Example 1, the reaction materials were added in the form of external mixing spray coating, and the differences in reaction coating between three polyols with hydroxyl values of 415, 163 and 55 and isocyanate (PAPI) were compared. The release rate of the coated sample was measured by water immersion method, and the structure is shown in Table 2.

[0041] Table 2 Effect of external mixing spray treatment on the reaction of different polyurethane coatings

[0042]

[0043] The reaction rate between polyols with different hydroxyl values and PAPI is quite different. Three kinds of polyols with different hydroxyl values were used in this experiment. In the test, it was found that No. 1 treatment had the best fluidization state in the whole process. Therefore, as a polyurethane coating, the reaction speed of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com