A method for increasing the formation rate of anaerobic ammonium oxidation granular sludge

A technology of anaerobic ammonium oxidation and anammox bacteria, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Irreversible damage to oxidizing bacteria and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

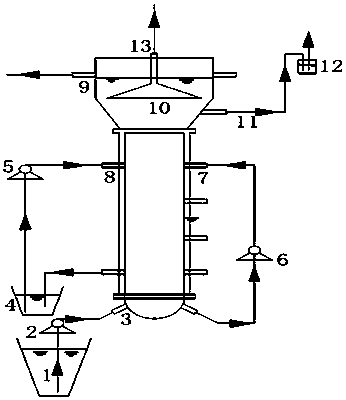

[0023] Concrete implementation steps and effects of the present invention are:

[0024] ①Using the actual first-level treatment of farm fecal wastewater and brewing wastewater (mixed according to a certain ratio as the nutrient source for anaerobic ammonium oxidation granular sludge), control the influent NH 4 + -N and NO 2 — -N mass concentration ratio is 1.2:1, C / N mass concentration ratio is less than 0.5.

[0025] ② Use the mixture of anaerobic sludge and dairy farm manure as inoculation sludge to inoculate the UASB reactor, in which the MLSS of the mixed sludge mixed culture is 3400mg / L, the MLVSS is 2200mg / L, and PAC 2~3mg / L is added and PAM0.5mg / L.

[0026] ③The culture temperature is controlled at 35±3°C, and the pH is controlled at 7.5-8.5.

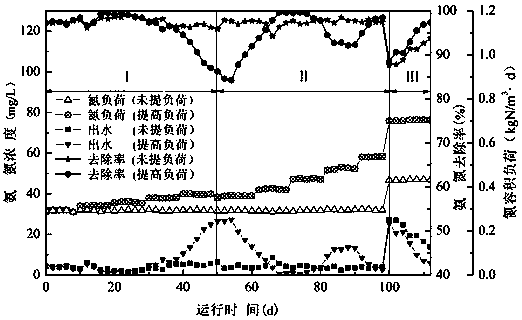

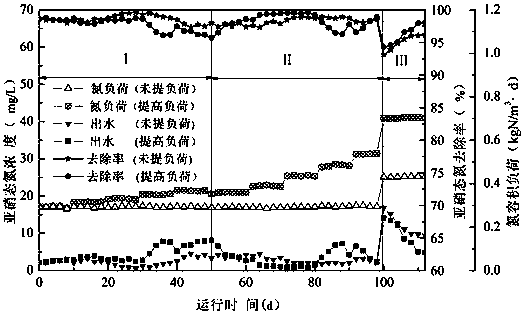

[0027] ④The process is divided into three stages: the first stage is the substrate promotion stage, the initial concentration of ammonia nitrogen in the influent is about 150mg / L, keeping other conditions unchanged, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com