A gas distribution plate for vibrating fluidized bed

A gas distribution plate and plate body technology, which is applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of distribution plate thickness, high probability of collision between particles and cone cap, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

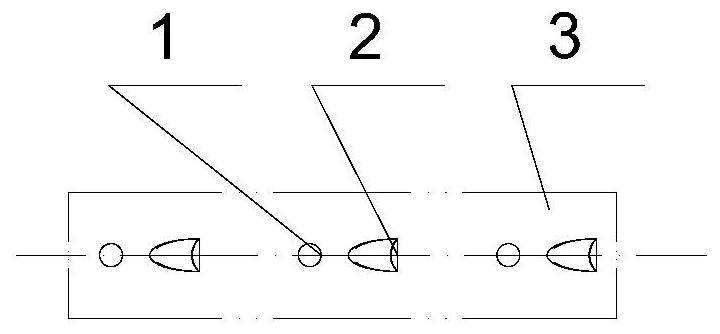

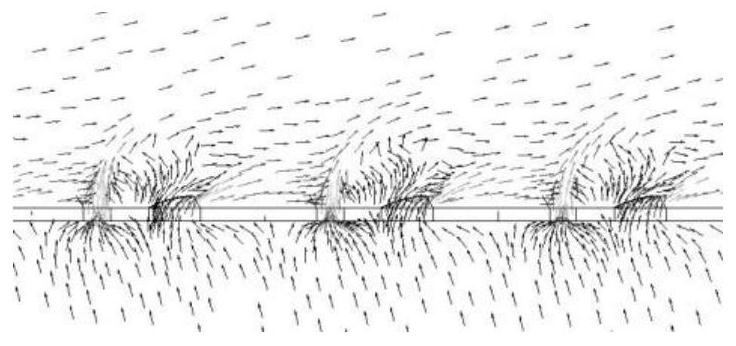

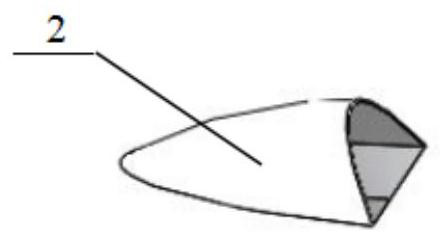

[0048] Figure 8 An arrangement of gas distribution holes is given. Straight holes 1 are arranged in an equilateral triangle with side length L 3 = L 4 =20mm, α=60°, a straight hole 1 is arranged on the opposite side of the opening direction of each ellipsoidal curved surface guide hole 2 with a chamfered angle, and the exit of the ellipsoidal curved surface guide hole 2 with a chamfered angle is to the opposite side of the opening direction The center distance L of the set straight hole 1 2 is 15.5mm. Ellipsoidal surface guide hole with chamfer 2 long L 1 , width B 1 , high H 1 They are 8mm, 5.5mm, and 2mm respectively, and the cutting angle θ is 120°. The matching straight hole 1 has a diameter of 4mm, and the diameter of the straight hole is 0.73 times the width of the guide hole on the ellipsoidal surface with chamfered corners. The plate body 3 has a thickness of 2mm. use Figure 8 The structure of the gas distribution plate is shown, and the size of the distrib...

Embodiment 2

[0050] Figure 9 A gas distribution plate arrangement is given. The straight holes 1 are arranged in a rectangle, and the distance between the centers of two adjacent straight holes is L 5 =35mm, distance L between two adjacent rows of straight holes 6 = 20mm. A straight hole 1 is arranged on the opposite side of the opening direction of each ellipsoidal curved surface guide hole 2 with a chamfered angle, and the center distance from the exit of the ellipsoidal curved surface guide hole 2 with a chamfered angle to the straight hole 1 set on the opposite side of the opening direction L 2 is 15.5mm. Ellipsoidal surface guide hole with chamfer 2 long L 1 , width B 1 , high H 1 They are 8mm, 5.5mm, and 2.04mm respectively, and the cutting angle θ is 90°. The matching straight hole 1 has a diameter of 5.5mm, and the diameter of the straight hole is 1 time of the width of the guide hole on the ellipsoidal surface with chamfered corners. The plate body 3 has a thickness of 2...

Embodiment 3

[0052] Figure 10 A gas distribution plate arrangement method is given, the straight holes 1 are arranged in a square, and the distance between the centers of two adjacent straight holes is L 5 =35mm, distance L between two adjacent rows of straight holes 6 = 35mm. A straight hole 1 is arranged on the opposite side of the opening direction of each ellipsoidal curved surface guide hole 2 with a chamfered angle, and the center distance from the exit of the ellipsoidal curved surface guide hole 2 with a chamfered angle to the straight hole 1 set on the opposite side of the opening direction L 2 is 15.5mm. Ellipsoidal surface guide hole with chamfer 2 long L 1 , width B 1 , high H 1 They are 8mm, 5.5mm, and 1.31mm respectively, and the cutting angle θ is 165°. The matching straight hole 1 has a diameter of 7mm, and the diameter of the straight hole is 1.27 times the width of the guide hole on the ellipsoidal surface with chamfered corners. The plate body 3 has a thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com