MEMS microphone and forming method thereof

A technology of microphone and cavity, applied in the field of MEMS microphone and its formation, to achieve the effect of compact structure and avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] As described in the background art, existing MEMS microphones are noisy during use. In view of the above technical problems, the present invention provides a first protrusion on the single-arm beam as a movable sensitive film near the free end area to reduce the probability of the single-arm beam contacting other parts in the cavity. In addition, the first The protrusion is also covered with an insulating layer, so that even if the first protrusion contacts other components due to electrostatic adsorption, static charges will not be released through the movable sensitive film, thus avoiding the generation of noise in the MEMS microphone. The objectives, features, and advantages can be more obvious and understandable, and specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

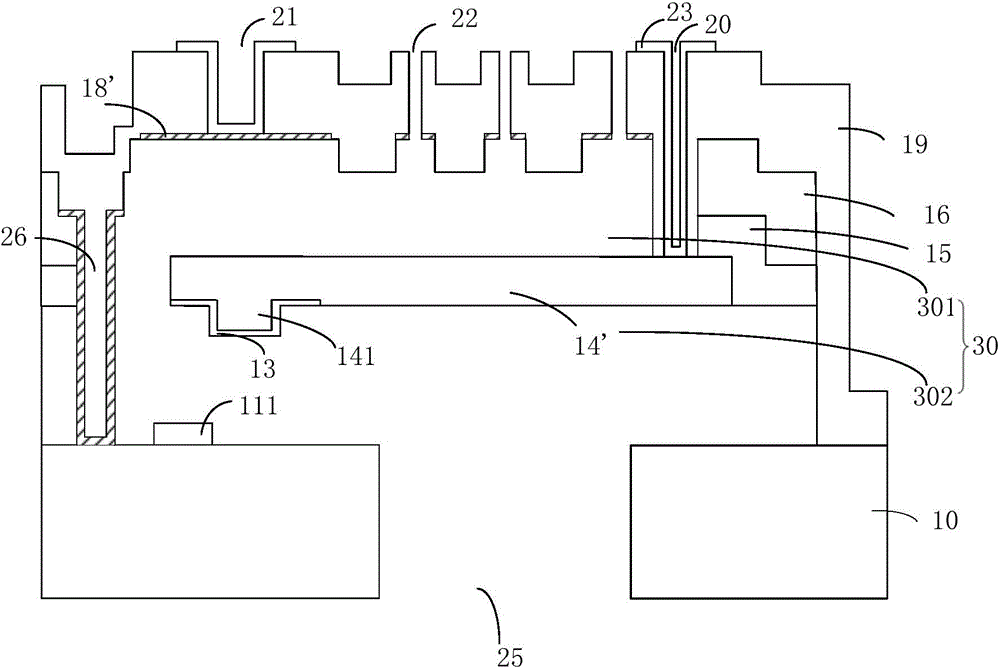

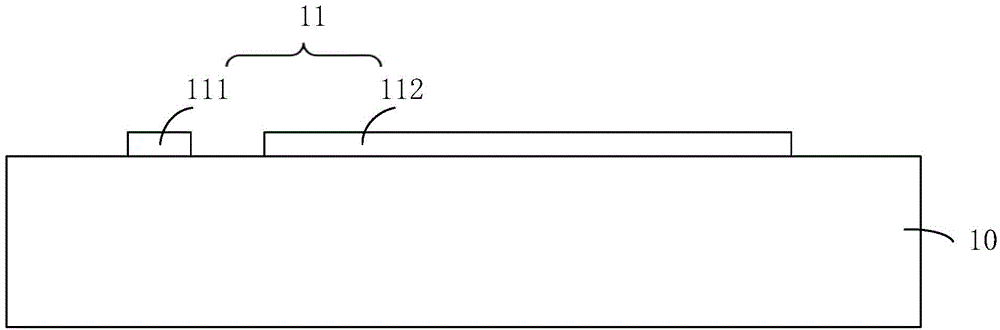

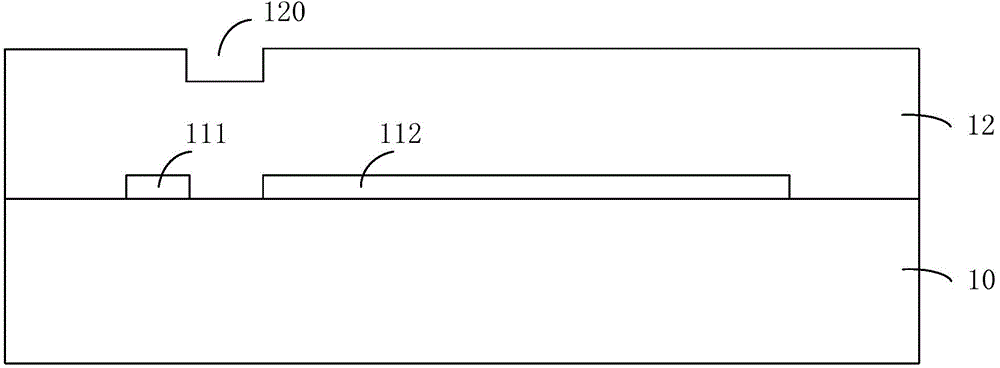

[0047] figure 1 Is a schematic structural diagram of a MEMS microphone provided by an embodiment of the present invention; Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com