Carbon material for negative electrode of lithium secondary battery, method for producing the same, negative electrode of lithium secondary battery and lithium secondary battery

A technology for lithium secondary batteries and negative electrodes, applied in the fields of carbon materials for negative electrodes of lithium secondary batteries and their manufacture, negative electrodes of lithium secondary batteries, and lithium secondary batteries, capable of solving problems such as negative electrode damage and suppressing the reduction of electrical conductivity , excellent charge-discharge cycle characteristics, and the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 135 parts by mass of a novolak-type phenolic resin (PR-50237 manufactured by Sumitomo Bakelite Co., Ltd.) and 25 parts by mass of hexamethylenetetramine (manufactured by Mitsubishi Gas Chemical Co., Ltd.) as carbon precursors were mixed with 86 mL of ethanol, An ethanol solution in which the total amount of the novolak-type phenolic resin and hexamethylenetetramine accounts for 70% by mass of the whole amount was obtained.

[0057] To 228 parts by mass of this ethanol solution, 100 parts by mass of silicon monoxide powder (average particle diameter 6 μm), 0.0043 parts by mass of iron nitrate, 0.00076 parts by mass of copper nitrate, 0.00104 parts by mass of molybdenum nitrate and 0.0011 parts by mass of aluminum powder (above, Kanto Chemical Co., Ltd.) was mixed for 3 minutes at room temperature with a high-speed mixer (homodisper manufactured by Primix Co., Ltd.) at a rotation speed of 3000 rpm to obtain 325 g of a compounded resin.

[0058] 300 g of the above blended ...

Embodiment 2

[0062] The procedure of Example 1 was repeated, but the holding time of the pulverized compound resin in the carbonization step at 1100° C. was changed from 6 hours to 1 hour.

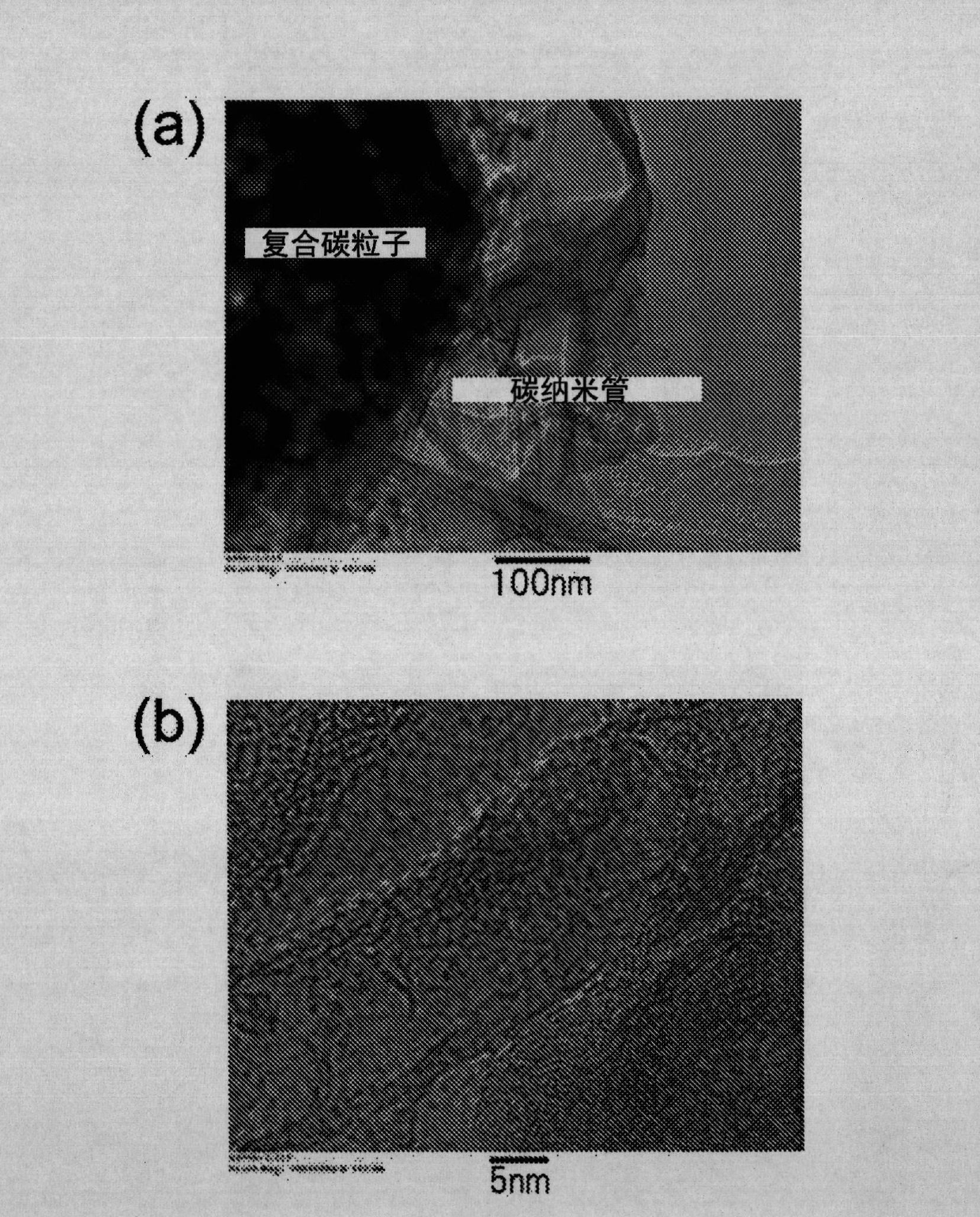

[0063] Observation of the obtained composite carbon material by a scanning electron microscope, the result (electron micrograph) is shown in image 3 middle. from image 3 It can be seen that carbon nanofibers and the like are generated from the particle surfaces of the composite carbon material and are confirmed to surround these particles.

Embodiment 3

[0065] To 228 parts by mass of a 70 mass % ethanol solution obtained in the same manner as in Example 1, 100 parts by mass of silicon monoxide powder (average particle diameter 6 μm) and 110 ppm of Fe (0.07 parts by mass of iron nitrate) were added, and This was mixed in the same manner as in Example 1 in the above-mentioned high-speed mixer to obtain 328 g of compounded resins. From 300 g of the blended resin, a composite carbon material was obtained in the same manner as in Example 1.

[0066] Observation results of composite carbon materials by scanning electron microscope, and figure 1 Similarly, it was confirmed that carbon nanofibers and the like were generated from the particle surfaces of the composite carbon material and surrounded these particles (not shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com