Negative electrode active material for lithium secondary battery and method for manufacturing same

A negative electrode active material and lithium secondary battery technology, applied in the direction of electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of short circuit, unrealized cycle life and long life, and achieve the suppression of cracks and micronization, and the reduction of volume change , the effect of shrinkage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

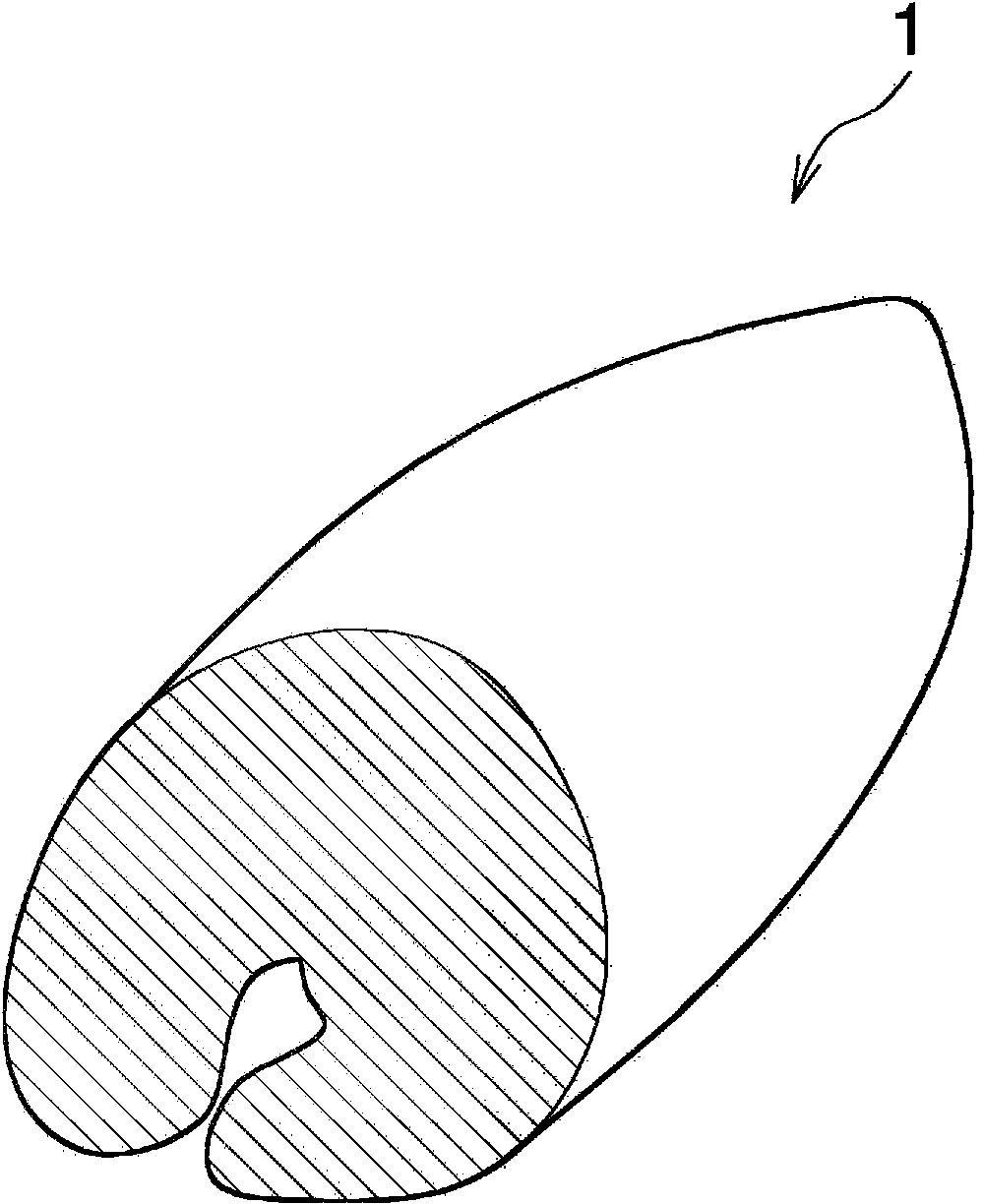

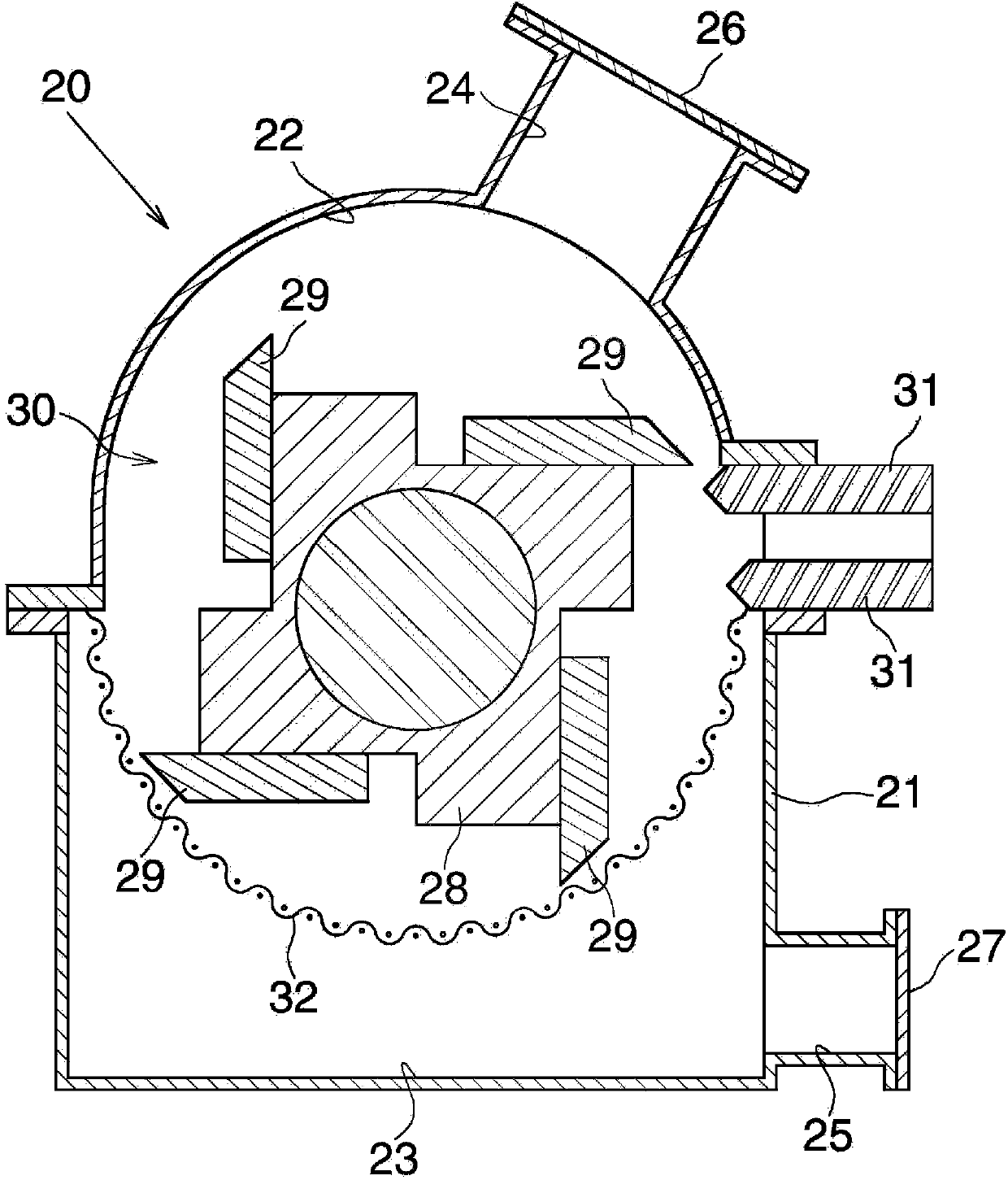

[0073] A commercially available aluminum foil with a thickness of 0.12mm made of Al with a purity of 99.9% by mass is divided into small pieces by a shredder device, and passed through a sieve with a mesh size of 0.045mm (based on JIS Z8801-1) Formed mesh screen (32) figure 2 The pulverization apparatus shown performs pulverization to produce a negative electrode active material made of powder. The particles in the obtained negative electrode active material are of a size that can pass through a sieve with a mesh size of 0.045 mm (based on JIS Z8801-1), and the specific surface area of the powder based on the BET method is 0.6 m 2 / g.

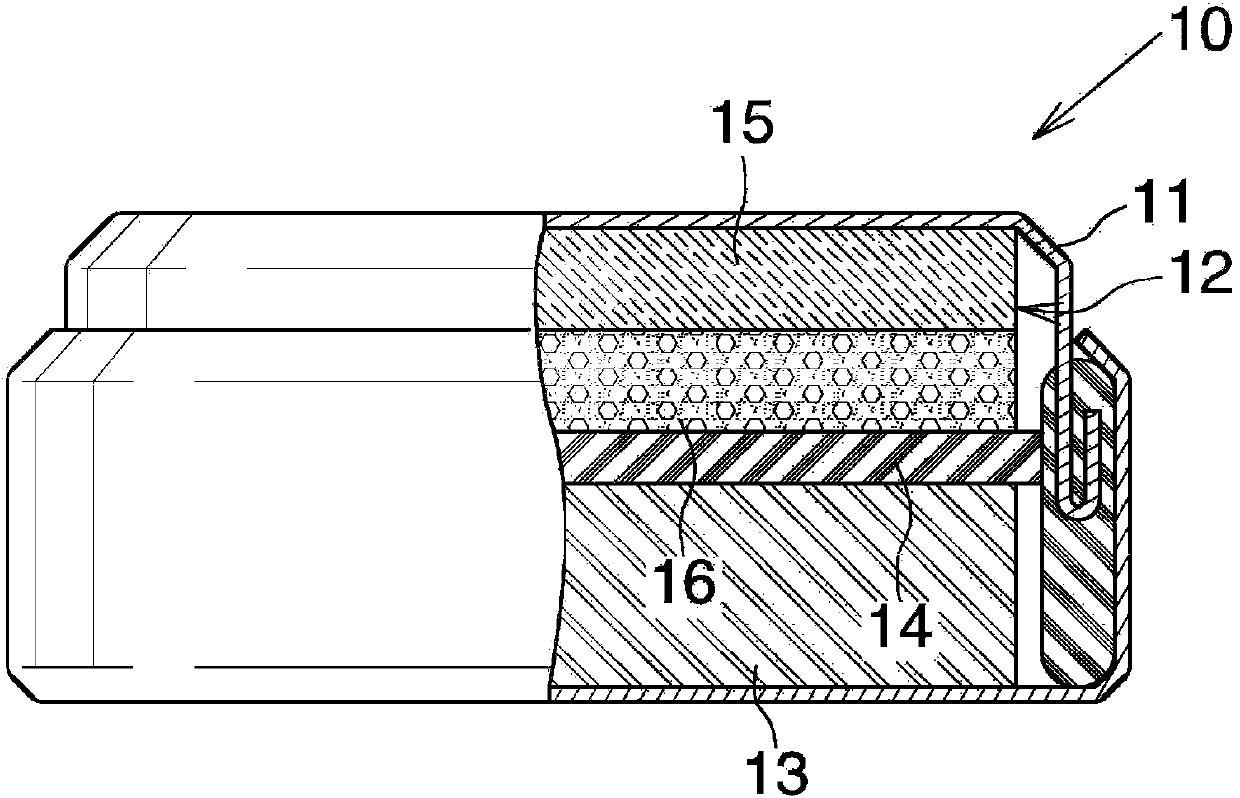

[0074] Next, the negative electrode active material: 90 parts by mass, the binder formed by polyvinylidene fluoride: 5 parts by mass and the conduction aid formed by acetylene black: 5 parts by mass were mixed, and the mixture was coated on a surface with a thickness of 10 μm. on the current collector formed of copper foil. Then, using 1c...

Embodiment 2

[0076] After a commercially available aluminum foil with a thickness of 0.12mm made of Al with a purity of 99.9% by mass was divided into small pieces by a shredder, it was passed through a mesh having a mesh size of 0.045mm (based on JIS Z8801-1). (32) figure 2 The pulverization device shown performs pulverization to make a powder. The particles in the obtained powder were of a size capable of passing through a sieve with a mesh size of 0.045 mm (based on JIS Z8801-1).

[0077] Next, the particles of the powder obtained as described above were subjected to a chemical dissolution treatment for 40 minutes in 5N-HCl at a liquid temperature of 60° C. to produce a negative electrode active material. The specific surface area based on the BET method of the powder constituting the obtained negative electrode active material was 1.1 m 2 / g.

[0078] Next, the negative electrode active material: 90 parts by mass, the binder formed by polyvinylidene fluoride: 5 parts by mass and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com