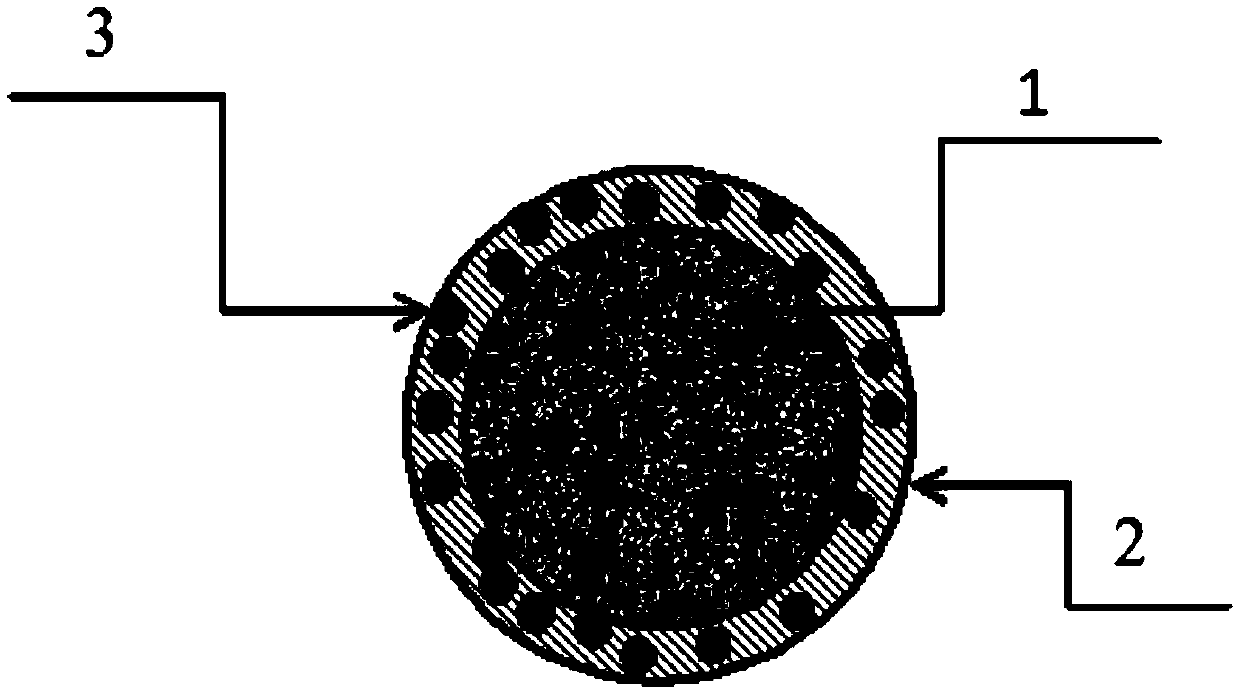

Lithium-sulfur battery positive-pole composite material with imitated cellular structure and preparation method thereof

A lithium-sulfur battery and composite material technology, applied in the field of electrochemical energy, can solve the problems of low cycle stability and capacity retention rate, affecting electrode stability, loss of active materials, etc., to enhance electrochemical activity and be beneficial to structural stability. , the effect of reducing the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] At 25°C, add 0.1g of PVP into 450mL of 0.1M hydrochloric acid solution, stir and ultrasonically disperse for 30min until transparent and clear, to obtain solution A, add 4.96g of sodium thiosulfate to 50mL of deionized water and stir to dissolve, to obtain solution B, The solution A was placed at a constant temperature of 30°C and stirred continuously, and the solution B was added dropwise to the solution A, and reacted for 2 hours. The product is centrifuged, washed and dried to obtain elemental sulfur particles. The obtained elemental sulfur particles and 0.05gSiO 2 (particle size of 15nm) and 1g of PVP were dispersed in 200mL of deionized water to obtain a suspension C, which was stirred and ultrasonicated for 20min to disperse the sulfur particles and silicon dioxide evenly. Stir the suspension C at room temperature, add 0.2 g of aniline monomer and 1 mL of concentrated hydrochloric acid dropwise, wait until it is uniformly dispersed, add 0.4 g of an aqueous soluti...

Embodiment 2

[0059] At 25°C, add 0.1g of PVP into 450mL of 0.1M hydrochloric acid solution, stir and ultrasonically disperse for 30min until transparent and clear, to obtain solution A, add 4.96g of sodium thiosulfate to 50mL of deionized water and stir to dissolve, to obtain solution B, Put the solution A at a constant temperature of 30° C., and stir continuously, and add the solution B to the solution A drop by drop, and react for 2 hours. The product is centrifuged, washed and dried to obtain elemental sulfur particles. The obtained elemental sulfur particles and 0.05gSiO 2 (particle size of 15nm) and 1g of PVP were dispersed in 200mL deionized water together to obtain suspension A, which was stirred and ultrasonicated for 20min to disperse the sulfur particles and silicon dioxide evenly. Stir the suspension A at room temperature, add 0.2 g of pyrrole monomer dropwise, and wait until it is uniformly dispersed, add 0.3 g of an aqueous solution of ferric chloride, continue to stir and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com