Feeding device and method for cadmium-removing boiling purification tank system

A technology of a feeding device and a feeding method, which is applied in the direction of improving process efficiency, can solve the problems of unavoidable air mixing into the system, and it is difficult to achieve closed feeding, etc., and achieves the effect of simple structure, convenient operation and realization of circulation balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

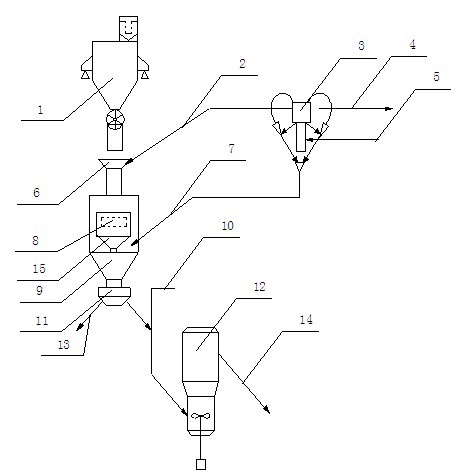

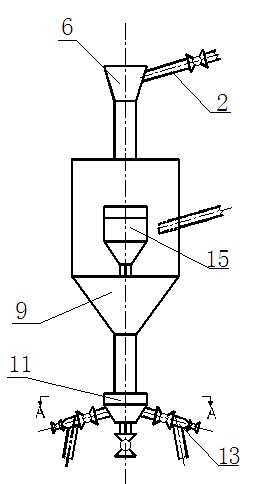

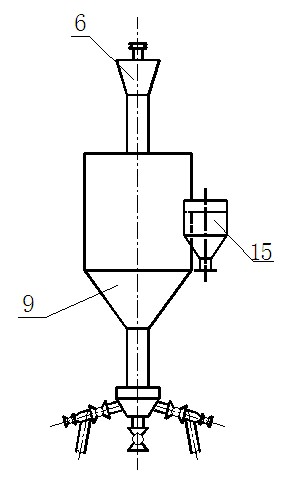

[0028] A feeding device for cadmium removal boiling purification tank system, such as figure 1 As shown, it is applied to a cadmium removal boiling purification tank system including 5 cadmium removal boiling purification tanks 12 and a hydrocyclone 3 in series, and the feeding device of the cadmium removal boiling purification tank system includes zinc powder stacked vertically up and down and hermetically connected The slurryer 6, the liquid sealer 9, the zinc powder slurry distributor 11, the outlet of the zinc powder bin 1 is set on the zinc powder slurryer 6, and the upper part of the zinc powder slurryer 6 is a bell mouth with the opening facing upwards, The lower part is a cylinder, and the side of the zinc powder slurryer 6 is provided with a zinc powder slurry solution pipeline 2 connected with the overflow port of the hydrocyclone 3; the hydrocyclone overflow pipeline 4 of the hydrocyclone 3 conveys hydraulic The cyclone overflow material, the outlet pipe 5 of the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com