Device and method for water-cooling hot wire argon tungsten-arc welding of austenitic stainless steel tube

A technology of austenitic stainless steel and argon tungsten arc welding, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the welding characteristics that cannot exert the high efficiency of mechanical hot wire tungsten argon arc welding, increase hot cracks and welding joint sensitization, uncontrollable interlayer temperature, etc., to achieve the effect of large linear expansion coefficient, prevention of intergranular corrosion, and slow height change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

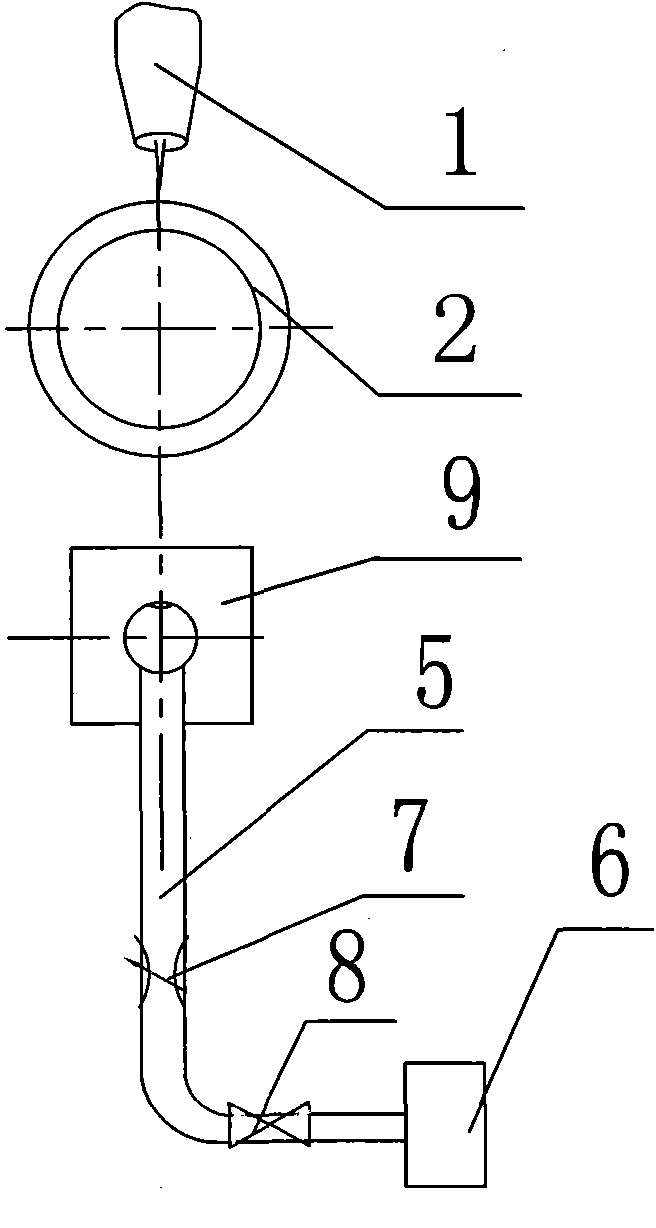

[0025] The method of water-cooled hot wire tungsten argon arc welding of austenitic stainless steel tubes, firstly prepares before welding, adjusts the height and position of the welding torch, connects the straight austenitic stainless steel tubes and adjusts the position of the cooling water supply, and the gun of the welding equipment And adopt the same gas path protection, when the welding primer and the pipe is rotated to 270°, open the cooling water valve, and use the spray device to spray and cool the welded joint until all the primer, filling layer and cover layer are completed of welding.

Embodiment 2

[0027] In the water-cooled hot wire tungsten argon arc welding method for austenitic stainless steel tubes described in Example 1, the spray device includes nozzles with various apertures. When the diameter of the spray hole of the water-cooled nozzle is 0.5mm, select When the height of the nozzle relative to the workpiece is 30-50mm, the thickness of the single-layer weld is controlled below 1.5mm.

Embodiment 3

[0029] In the water-cooled hot wire tungsten argon arc welding method for austenitic stainless steel tubes described in embodiment 1 or 2, the position of the nozzle of the spray device is located directly below the welding port, and when the pipe diameter ranges from φ32mm to φ70mm, the The initial position of the nozzle above is 30mm from the lower surface of the pipe; during the welding process, the adjustment range in the up and down direction is 50mm, that is, the maximum distance between the upper surface of the nozzle and the lower surface of the pipe is 80mm. The direction adjustment range is ±50mm, facing the center of the weld seam; the axis of the nozzle is parallel to the axis of the pipe, and the water column sprayed by the nozzle is perpendicular to the surface of the pipe to ensure that the cooling water can be effectively sprayed to the weld joint Directly below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com