radial centrifugal turbine

A radial centrifugal and turbine technology, applied in the direction of preventing leakage, supporting elements of blades, stators, etc., can solve the problems of increasing system instability, generating large vibration, and small air intake flow, and improving work efficiency, The effect of avoiding vibration and increasing the intake air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The radial centrifugal turbine involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0022]

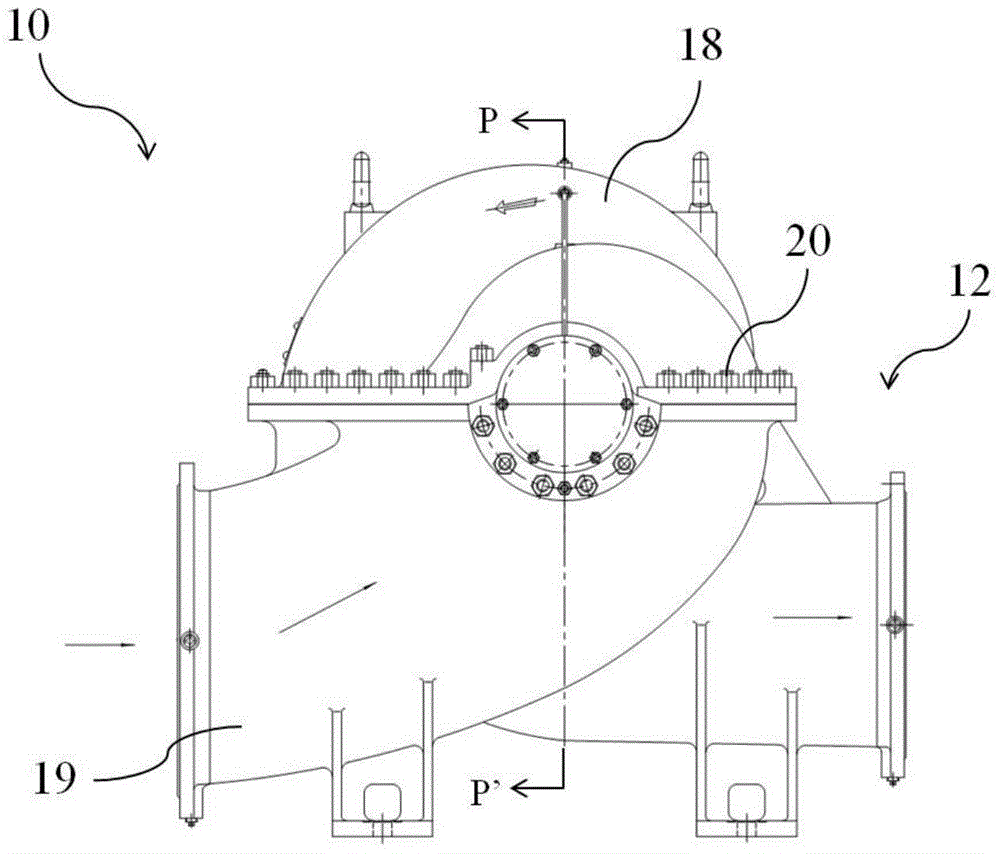

[0023] figure 1 is a schematic structural view of the radial centrifugal turbine of the embodiment;

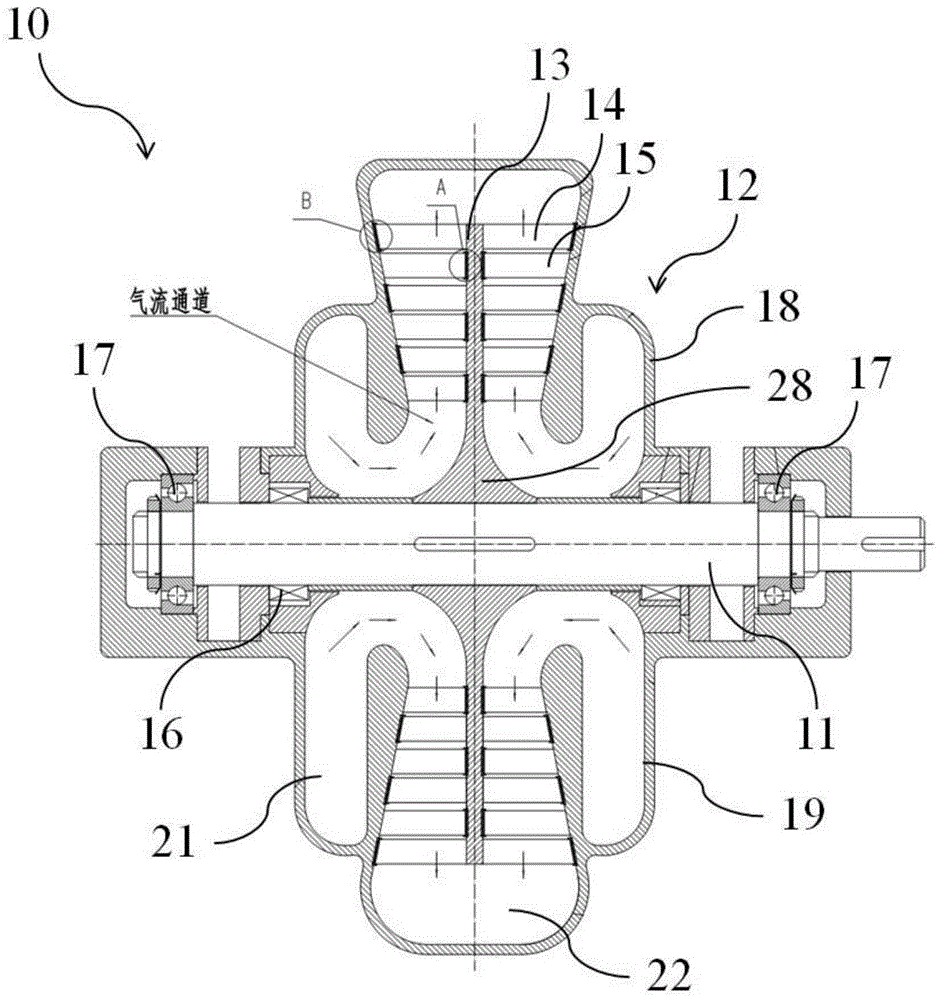

[0024] figure 2 yes figure 1 The cross-sectional view of the P-P' direction.

[0025] Such as figure 1 , 2 As shown, the radial centrifugal turbine 10 includes a rotating shaft 11 , a casing 12 , a disc 13 , multiple sets of moving blade cascades 14 , multiple sets of stationary blade cascades 15 and a sealing body 16 .

[0026] The rotating shaft 11 is rotatably fixed on the bearings 17 at both ends, and rotates under the drive of the wheel disc 12, and the rotating shaft 15 is connected to a generator or other working machines (not shown in the figure).

[0027] The housing 12 serves to protect the radial centrifugal turbine 10 . In this embodiment, the casing 12 includes an upper casing 18 and a lower cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com