Serrate corrugated padding and use thereof

A technology of corrugated packing and corrugated packing sheets, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of poor understanding of microscopic phenomena of two-phase flow on the surface of packing and poor separation effect , Difficulty in measuring the flow field distribution of two-phase flow, etc., to achieve the effects of facilitating engineering popularization and application, improving separation efficiency, reducing liquid holdup and vapor-liquid residence time in the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

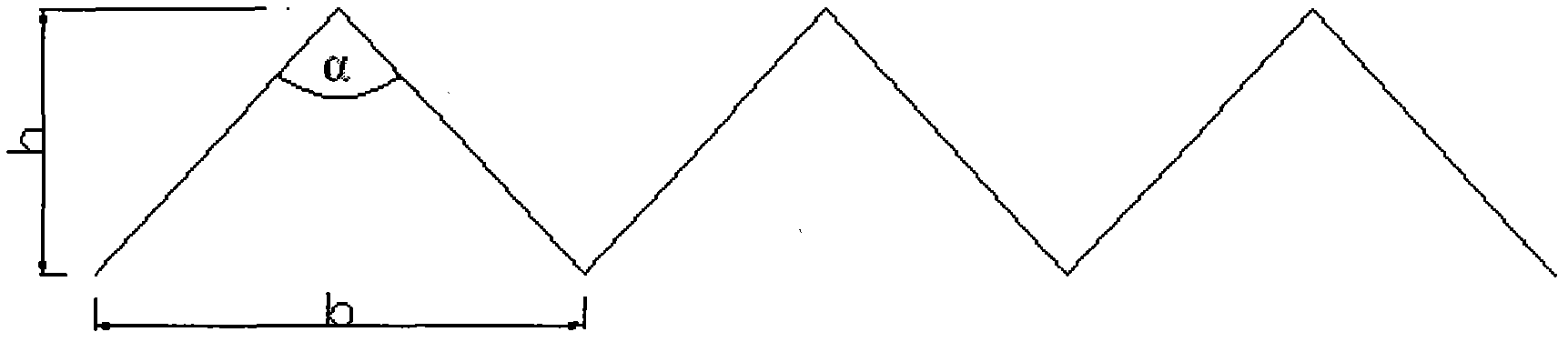

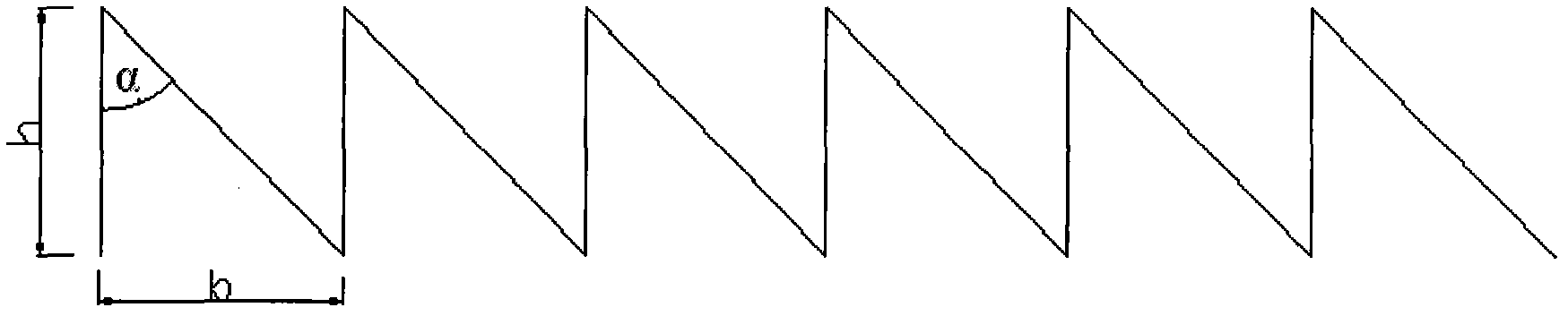

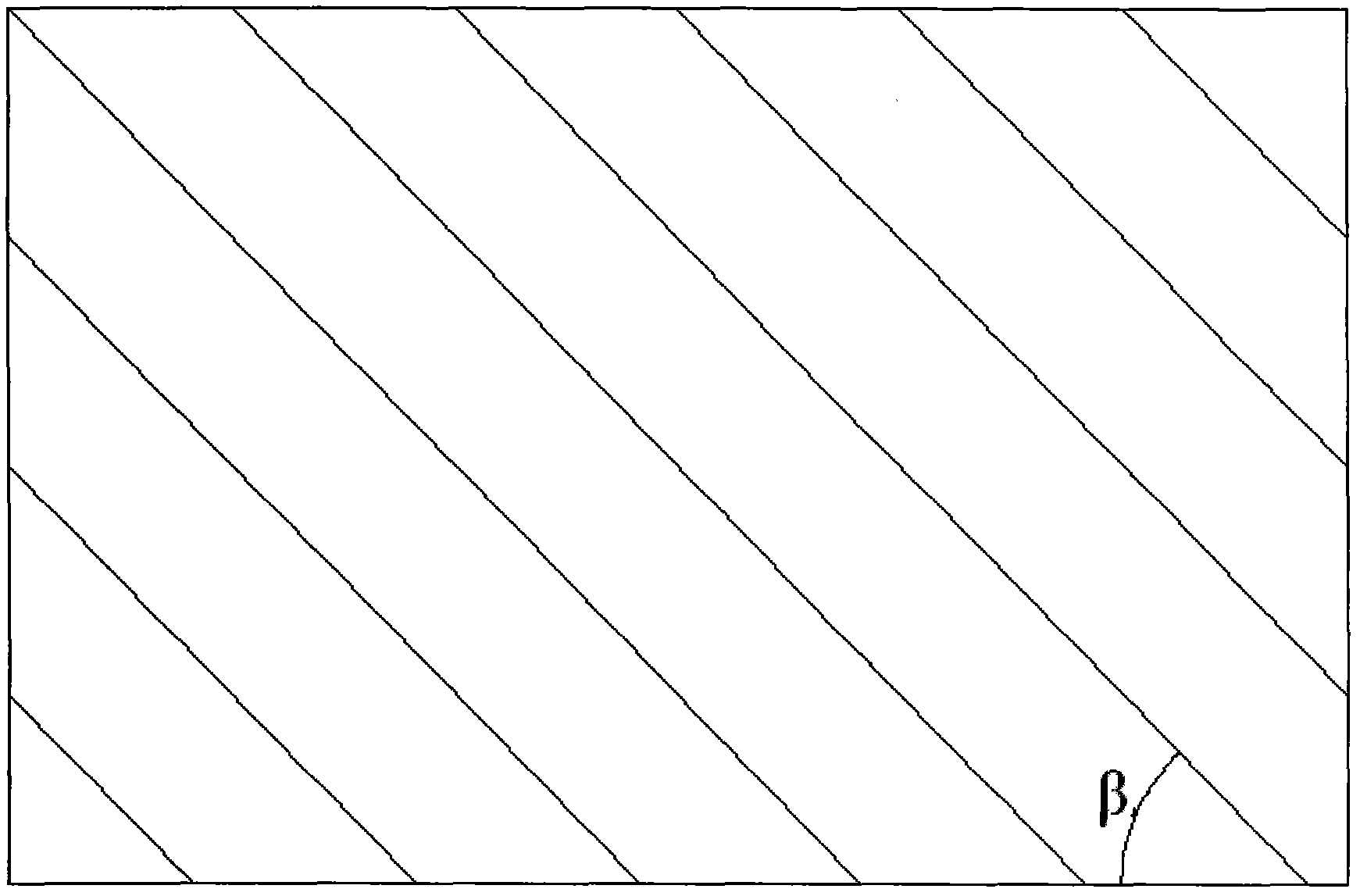

[0023] Such as Figure 2-3 As shown, use a stainless steel plate with a thickness of 1mm to punch a hole with a diameter of 5mm, the punching rate is 10%, and then roll it into a zigzag shape with a peak height h=4mm, a tooth profile angle α=60°, and a corrugation inclination angle β=30° Zigzag-pak corrugated packing, cut and combined into a packing disc with a diameter of 800mm and a disc height of 300mm. Instead of the traditional corrugated packing with a peak height of 4mm and a wave pitch of 8mm, it is used for xylene rectification, and the separation efficiency is greatly improved.

Embodiment 2

[0025] Use 100-mesh stainless steel wire mesh to punch a hole with a diameter of 5mm, the punching rate is 5%, and then roll it into a zigzag-shaped Zigzag- pak corrugated packing, cut and combined into a packing disc with a diameter of 30mm and a disc height of 30mm. Mounted on Separation Isotope 13 C's CO cryogenic rectification tower. Its separation efficiency is higher than the same peak height of 2.5mm, and its specific surface area is 1100m 2 / m 3 traditional corrugated packing.

Embodiment 3

[0027] Use an aluminum alloy plate with a thickness of 0.8mm, roll it into a zigzag-pak corrugated packing with a peak height of h=3mm, a tooth profile angle α=15°, and a corrugation inclination angle β=60°, and cut it into a diameter of 400mm. 200mm packing disc. Mounted on Separation Isotope 18 O of O 2 in the cryogenic distillation column. Its separation efficiency is higher than that of traditional Sulzer corrugated packing with the same peak height of 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com