Rotary cutting tool

A technology of cutting tools and tools, which is applied in the manufacture of tools, drilling accessories, metal processing, etc., can solve the problems of unsatisfactory dimensional accuracy of printed substrates, deterioration of processing surface accuracy, tool breakage, etc., and achieve excellent practicability and good cutting Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The action of the present invention will be shown with reference to the drawings, and preferred embodiments of the present invention will be briefly described.

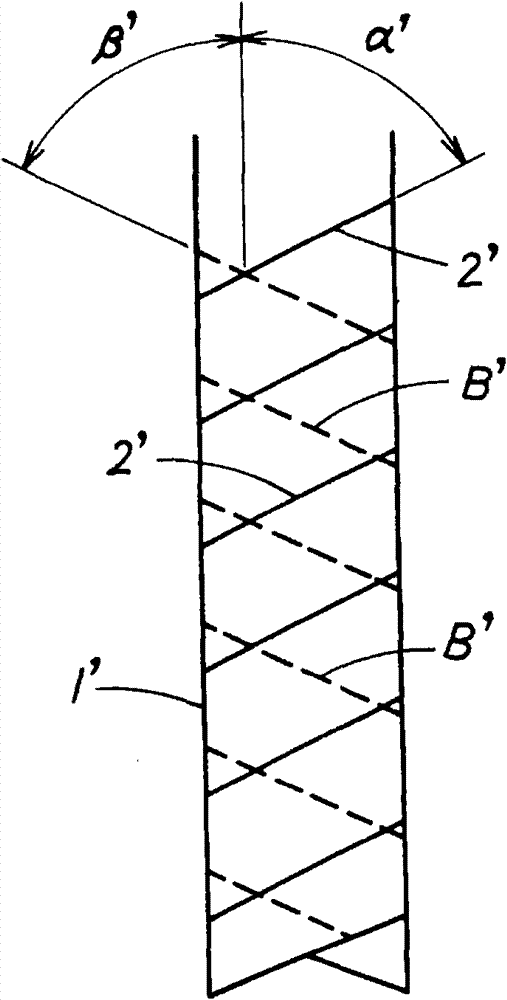

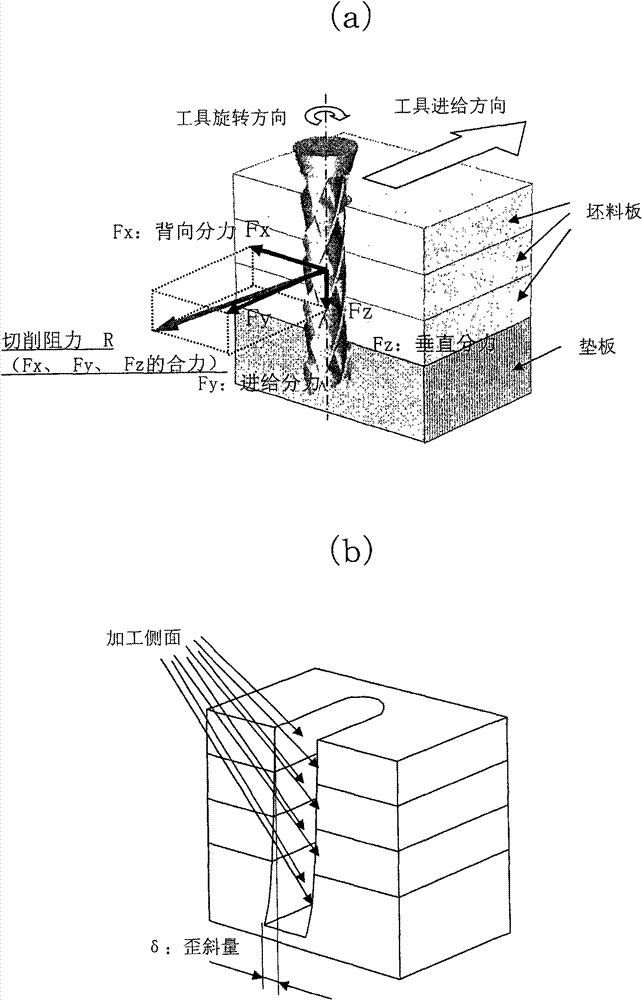

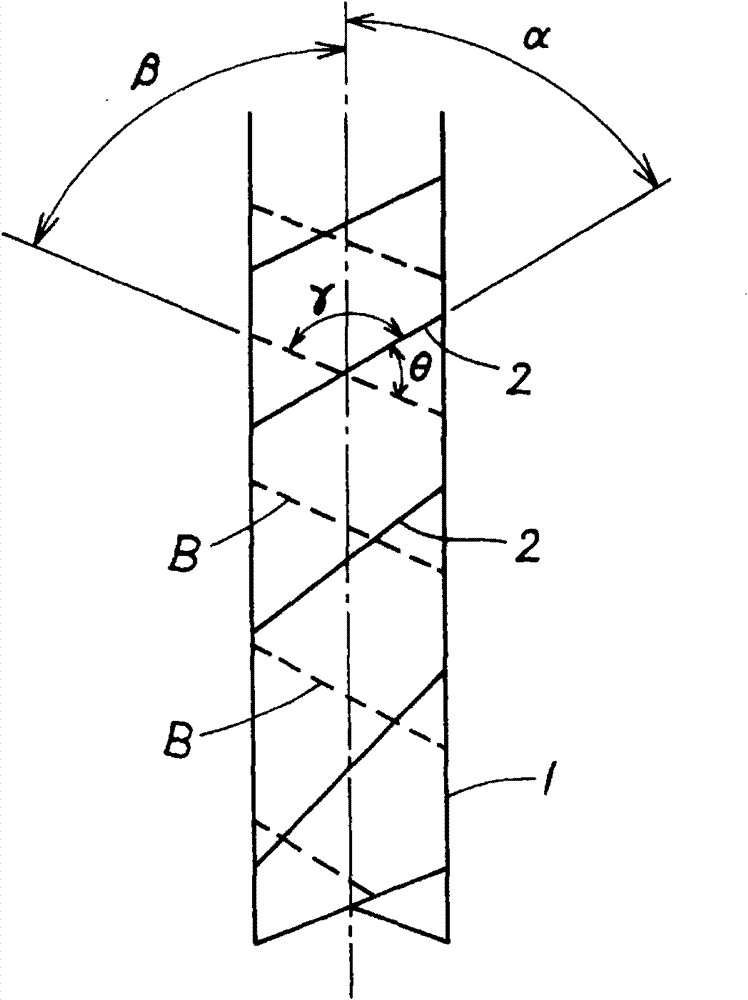

[0036] The workpiece is machined by bringing the tool body 1 into contact with the workpiece while rotating. At this time, since the helix angle α of the outer peripheral cutting edge 2 (flute 3 ) becomes smaller toward the tool end and larger toward the base end, skewing can be suppressed, thereby preventing the outer peripheral edge when the tool is pulled out from the substrate or the like. Chipped cutting edge. In addition, chips are less likely to be jammed on the base end side, and workability and breakage resistance are improved.

[0037] Specifically, since the helix angle α on the tip side of the tool is small, the skew of the tool body 1 can be suppressed. In particular, the amount of skew δ at the tip of the tool is remarkably small. At this time, the contact between the peripheral cutting edge and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com