Method for preparing rutile-type TiO2 thin film at room temperature

A rutile-type, gold-preparing technology, which is applied in the types of packaging items, metal material coating technology, ion implantation plating, etc., to achieve high anticoagulation, improve inhibition, and delay the formation of thrombus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Substrate ultrafine crystal / nanocrystalline titanium, surface film TiO 2 . Carry out by the step described in the technical scheme of the present invention. Thin films were prepared by JGP560CVI ultra-high vacuum multifunctional magnetron sputtering apparatus. Preparation of TiO 2 The background vacuum degree of thin film is 2.5×10 -5 Pa, substrate temperature is room temperature, target-substrate distance is 70mm. deposited TiO 2 The technology used in the film is direct current (DC) reactive magnetron sputtering technology. The target material is Ti with a purity of 99.99%. The flow rate is 45 sccm, the sputtering power is 160 W, and the sputtering time is 120 min.

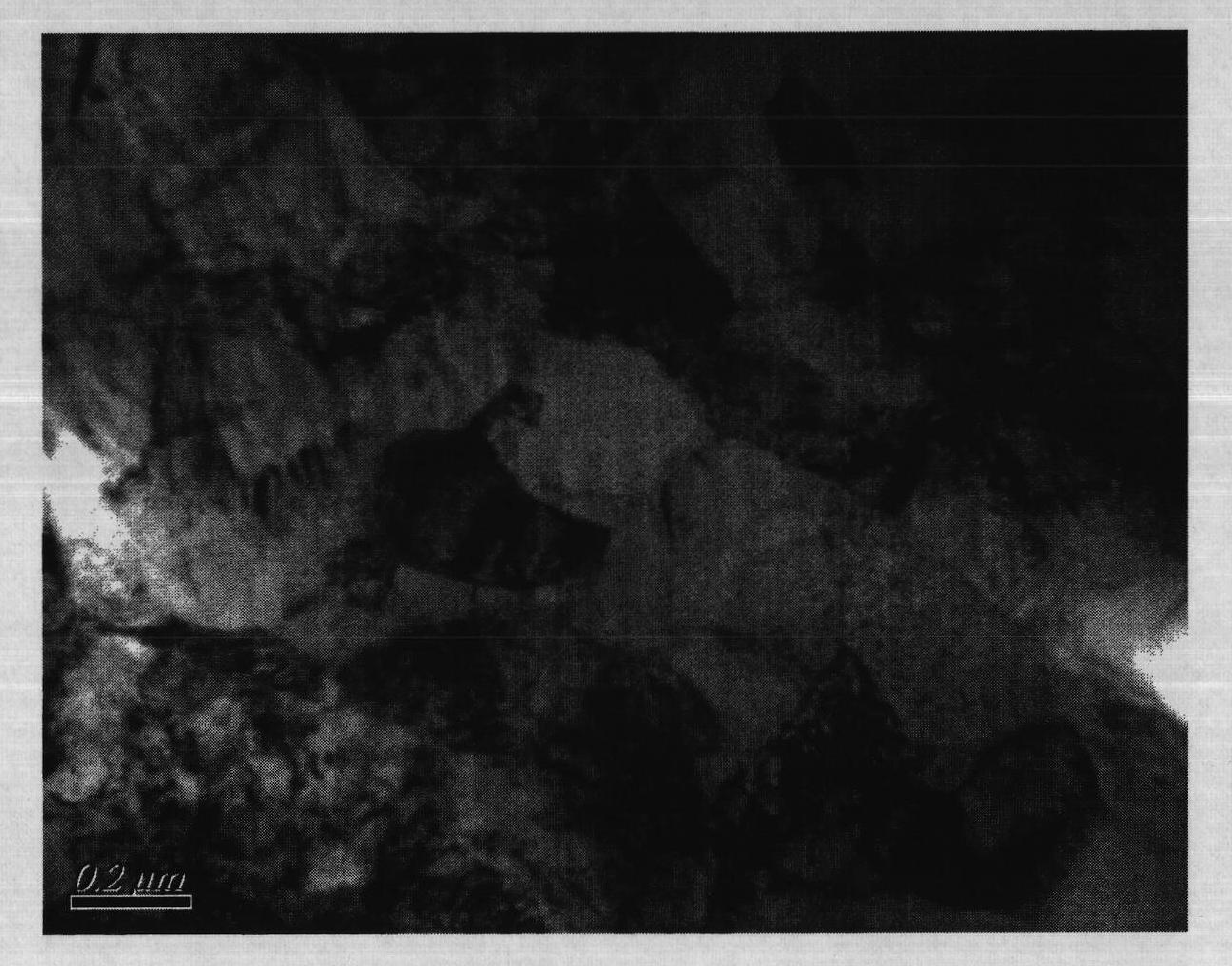

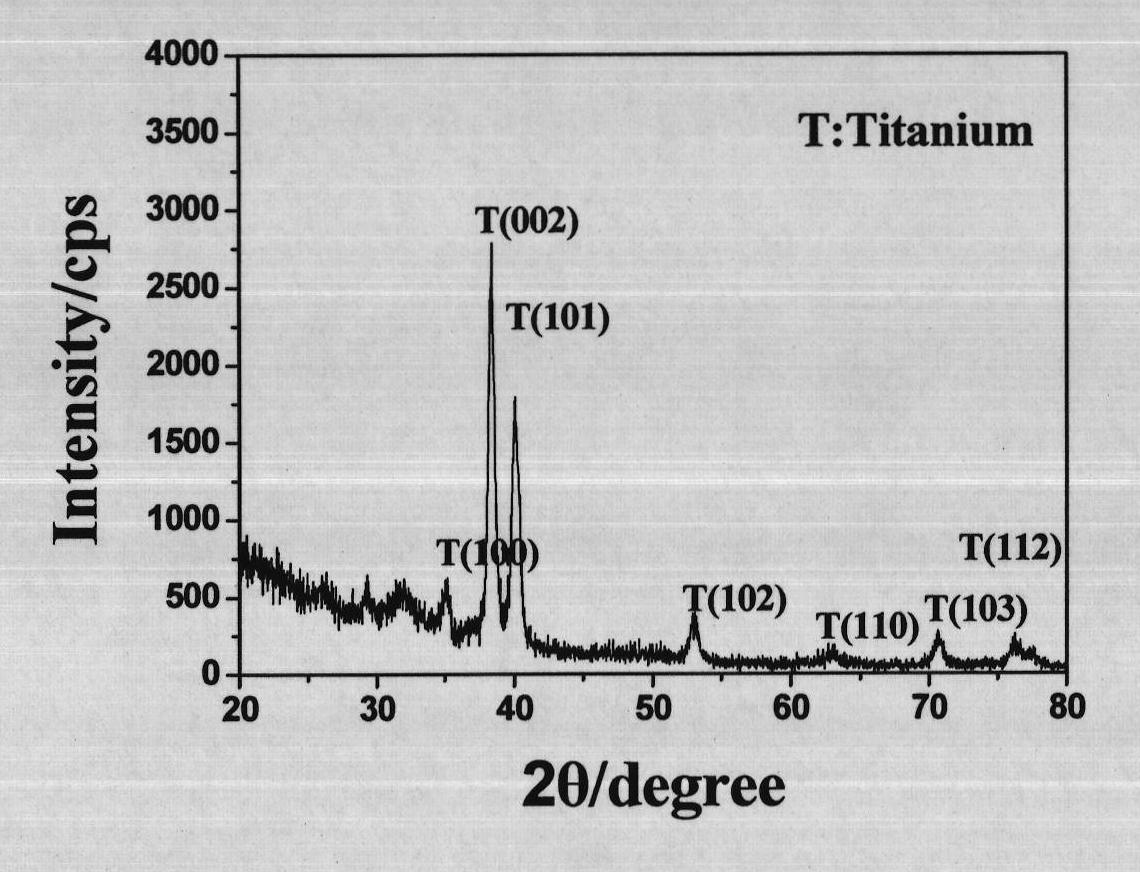

[0031] The microstructure of ultrafine-grained / nanocrystalline titanium substrates is a mixed structure of nanocrystalline (figure 1 ); its SADE map shows that the orientation between the ultrafine crystal / nanocrystalline titanium grains is a large angle ( figure 2 ); the half-peak w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com