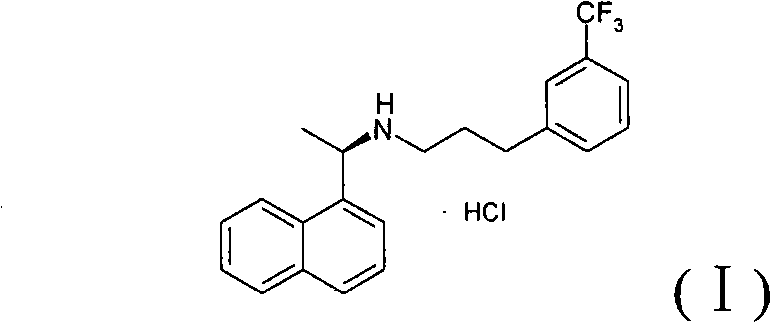

Preparation method of cinacalcet hydrochloride

A technology of cinacalcet hydrochloride and isopropyl titanate, which is applied in the new field of preparation of cinacalcet hydrochloride, can solve the problems of unfavorable industrial production, splitting of naphthaleneethylamine, serious by-products, etc., and achieve low cost , less environmental pollution, fewer reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

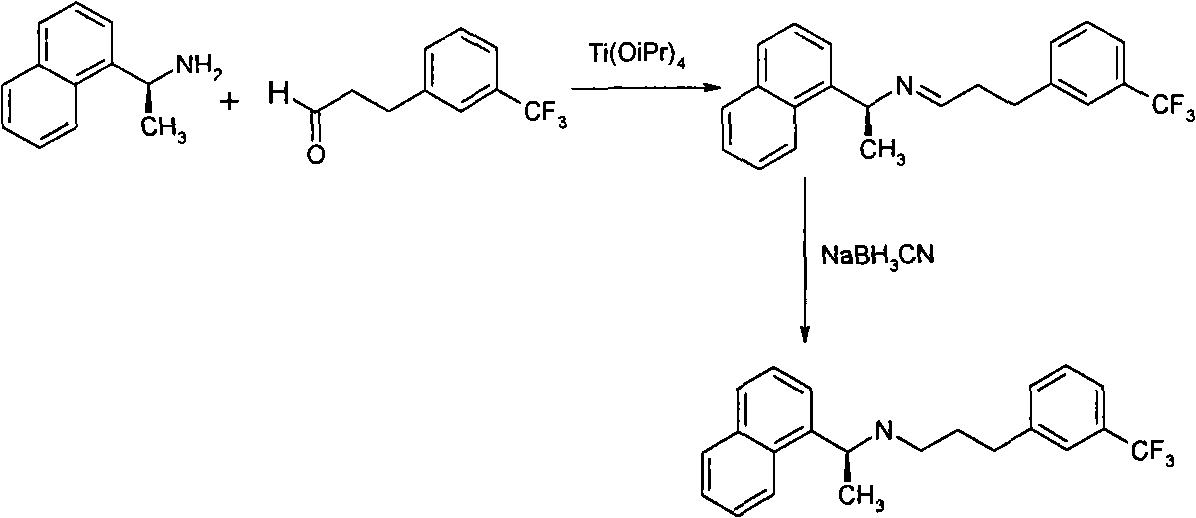

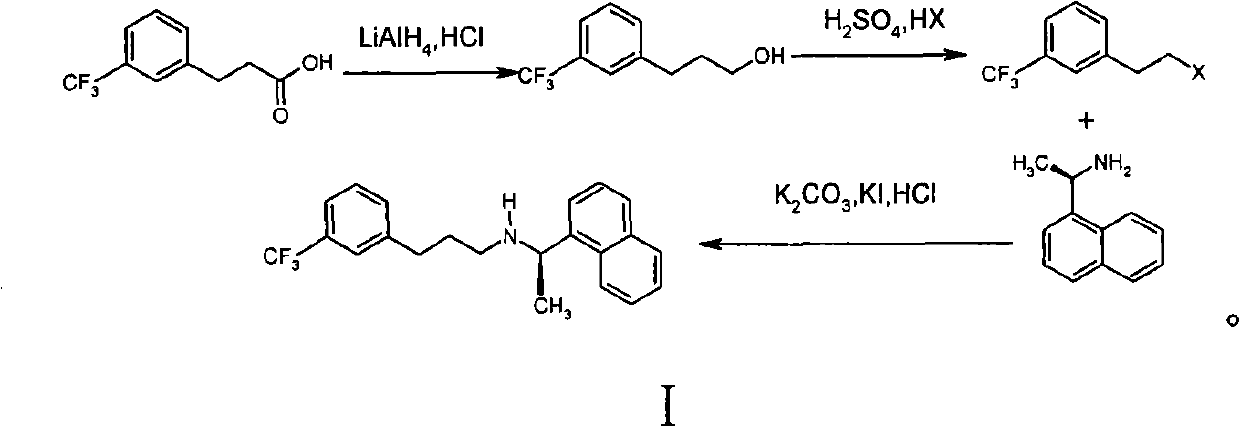

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below with reference to a specific embodiment, but the present invention is not limited to the following embodiment.

[0047] Step 1: Preparation of Compound (III)

[0048]1-Naphthoethyl ketone (1.7 g) was added to a 100 mL round-bottomed flask, dissolved in tetrahydrofuran (20 mL), (R)-tert-butylsulfinamide (2.2 g) was added, and the reaction mixture was heated to 70° C. , and then add 2.8 g of isopropyl titanate to the flask, and after about 10 minutes of adding, the reaction is incubated for 22 hours. The completion of the reaction was monitored by TLC, and the temperature was lowered to about 0°C. Sodium borohydride (0.5 g) was dissolved in tetrahydrofuran (3 mL), cooled to 0°C, and slowly added to the above reaction mixture for about 10 min. After the addition, heated to room temperature and kept stirring for 5 h. After completion of the reaction monitored by TLC, it was cooled to 0°C. After stirring for another 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com