Preparation method of electronic grade propylene glycol methyl ether acetate

A technology of propylene glycol methyl ether acetate and propylene glycol methyl ether, which is applied in the field of preparation of organic compounds, can solve the problems of solid waste and waste water polluting the environment, failure to meet electronic grade product standards, a large amount of solid waste gas and waste water, etc., and achieve reduction The generation of solid pollutants and waste liquid, good economic and environmental benefits, and the effect of reducing the content of metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

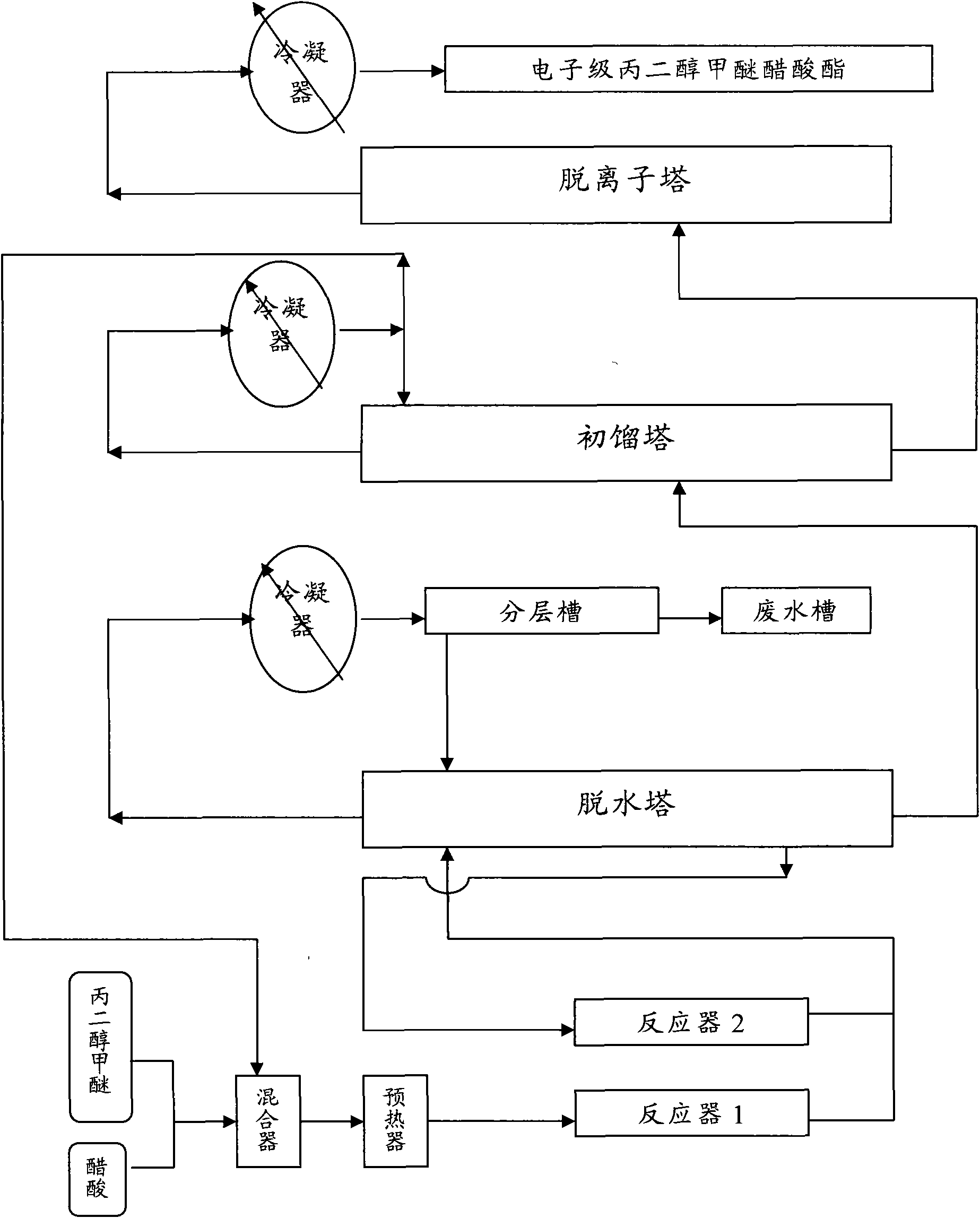

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

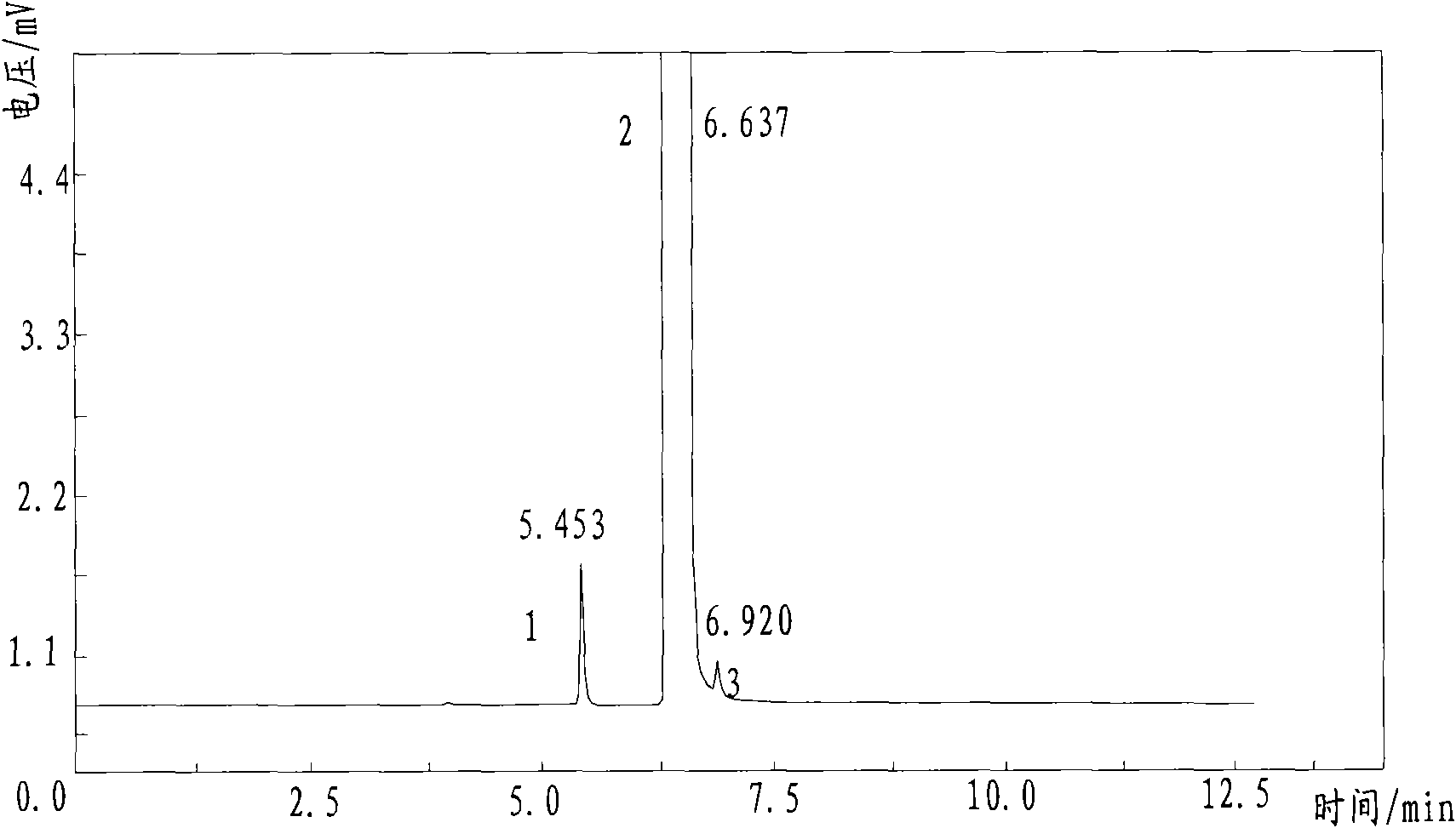

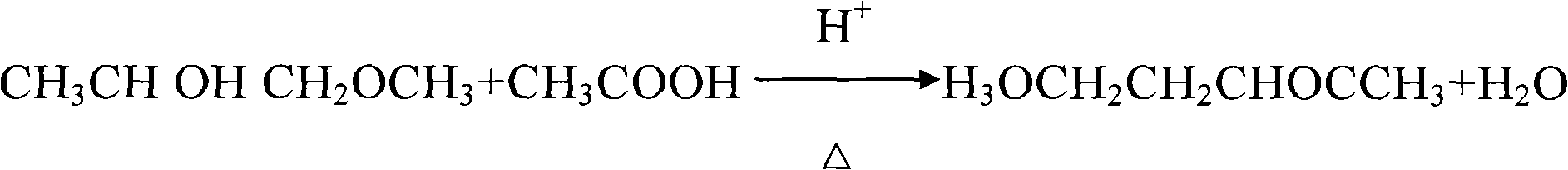

[0033] A method for preparing electronic-grade propylene glycol methyl ether acetate by continuous esterification, using propylene glycol methyl ether and acetic acid as raw materials, is characterized in that: a two-stage fixed-bed continuous esterification reaction is carried out using a strong acid cation resin catalyst, and the esterification system is in 60~100℃, the water generated in the esterification reaction is removed by azeotropic distillation; the esterification reactant is rectified, and the unreacted acetic acid is removed and recovered to obtain ordinary grade propylene glycol methyl ether acetate, which is then passed through the deionization tower , into electronic grade propylene glycol methyl ethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com