Vacuum pyrolysis test device of wasted electronic circuit board

An electronic circuit board, vacuum pyrolysis technology, applied in the direction of electronic waste recycling, solid waste removal, recycling technology, etc., can solve the problems of incomplete separation, water pollution, difficult treatment, etc., and achieve high comprehensive resource recycling rate , The effect of good economic benefit and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

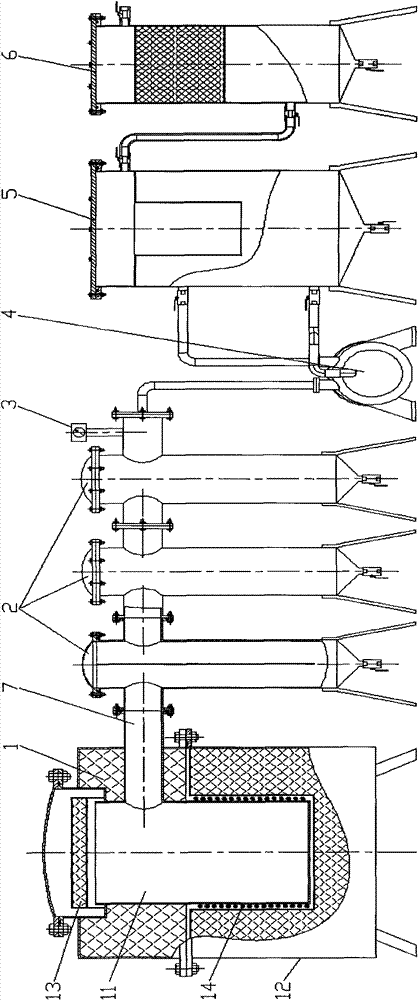

Image

Examples

Embodiment 1

[0026] a. Weigh 5 kilograms of waste circuit boards provided by a circuit board factory;

[0027] b. Cut the waste circuit board properly and put it into the charging barrel;

[0028] c. Put the charging barrel into the feeding chamber of the vacuum furnace, and cover the heat preservation cover and the furnace cover;

[0029] d. Turn on the mechanical water ring vacuum pump to vacuum up to about 5000 Pa;

[0030] e. Turn on the vacuum pump and heat the furnace body at the same time until the temperature of the feeding chamber wall rises to 500°C;

[0031] f. As the furnace temperature rises, the vacuum degree will drop to about 10000 Pa appropriately;

[0032] g. The furnace temperature is kept constant at 500°C for one hour. This stage is the pyrolysis stage of adding waste circuit boards. It can be judged by the temperature rise of the condenser that a large amount of pyrolysis organic gas enters the condenser;

[0033] h. During the pyrolysis process, the tail gas emiss...

Embodiment 2

[0040]n. Weigh 10 kilograms of waste circuit boards provided by a circuit board factory;

[0041] o. Cut the waste circuit board properly and put it into the charging barrel;

[0042] p. Put the charging barrel into the feeding chamber of the vacuum furnace, and cover the heat preservation cover and the furnace cover;

[0043] q. Turn on the mechanical water ring vacuum pump to vacuum up to about 5000 Pa;

[0044] r. Turn on the vacuum pump and heat the furnace body at the same time until the temperature of the feeding chamber wall rises to 500°C;

[0045] s. As the furnace temperature rises, the vacuum degree will drop to about 10000 Pa appropriately;

[0046] t. The furnace temperature is kept constant at 500°C for one and a half hours. This stage is the pyrolysis stage of adding waste circuit boards. It can be judged by the temperature rise of the condenser that a large amount of pyrolysis organic gas enters the condenser;

[0047] u. During the pyrolysis process, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com