Full-plastic heat exchanger water tank liner

A heat exchanger and water tank technology is applied in the field of the water tank liner of an all-plastic heat exchanger, which can solve the problems of large circulation resistance, large heat loss and high cost of the enamel liner, and achieves the elimination of an automatic water level control system and a small heat loss. , the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

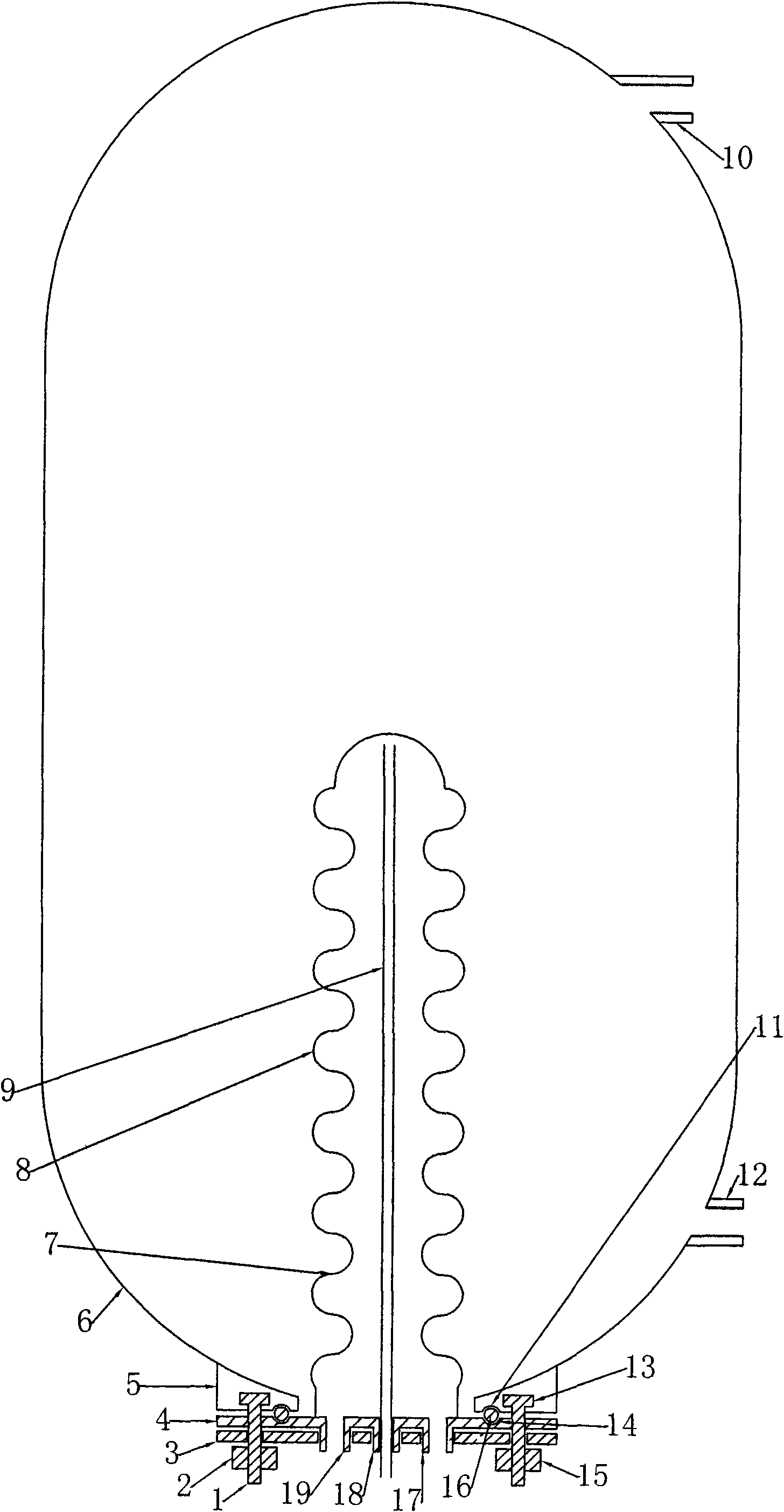

[0018] Below in conjunction with accompanying drawing, by embodiment, the present invention will be further described:

[0019] Water tank 6 is made of metal material, or metal enamel material, or polymer material, or modified polymer material, or reinforced polymer, or composite polymer material; seal ring groove 14, circulation pipe interface 17, Exhaust pipe interface 18, circulation pipe interface 19; there is an annular wave 8 on the heat exchange column 7, or a non-annular curved surface shell protrusion on the heat exchange column 7, or a tooth-shaped shell protrusion on the heat exchange column 7, and a Or it is a solid fin protrusion; the circular plate 4 and the heat exchange column 7 are made of polymer materials, or modified polymer materials, or reinforced polymer materials, or composite polymer materials; the seals on the circular plate 4 and the circular plate 4 The ring groove 14, the circulation pipe interface 17, the exhaust pipe interface 18, and the circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com