Halogen-free thermoplastic elastomer and manufacturing method thereof and environment-friendly electric wires and cables using halogen-free thermoplastic elastomer

A technology of thermoplastic elastomers and elastomers, applied in the direction of plastic/resin/wax insulators, rubber insulators, organic insulators, etc., can solve problems such as environmental pollution and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

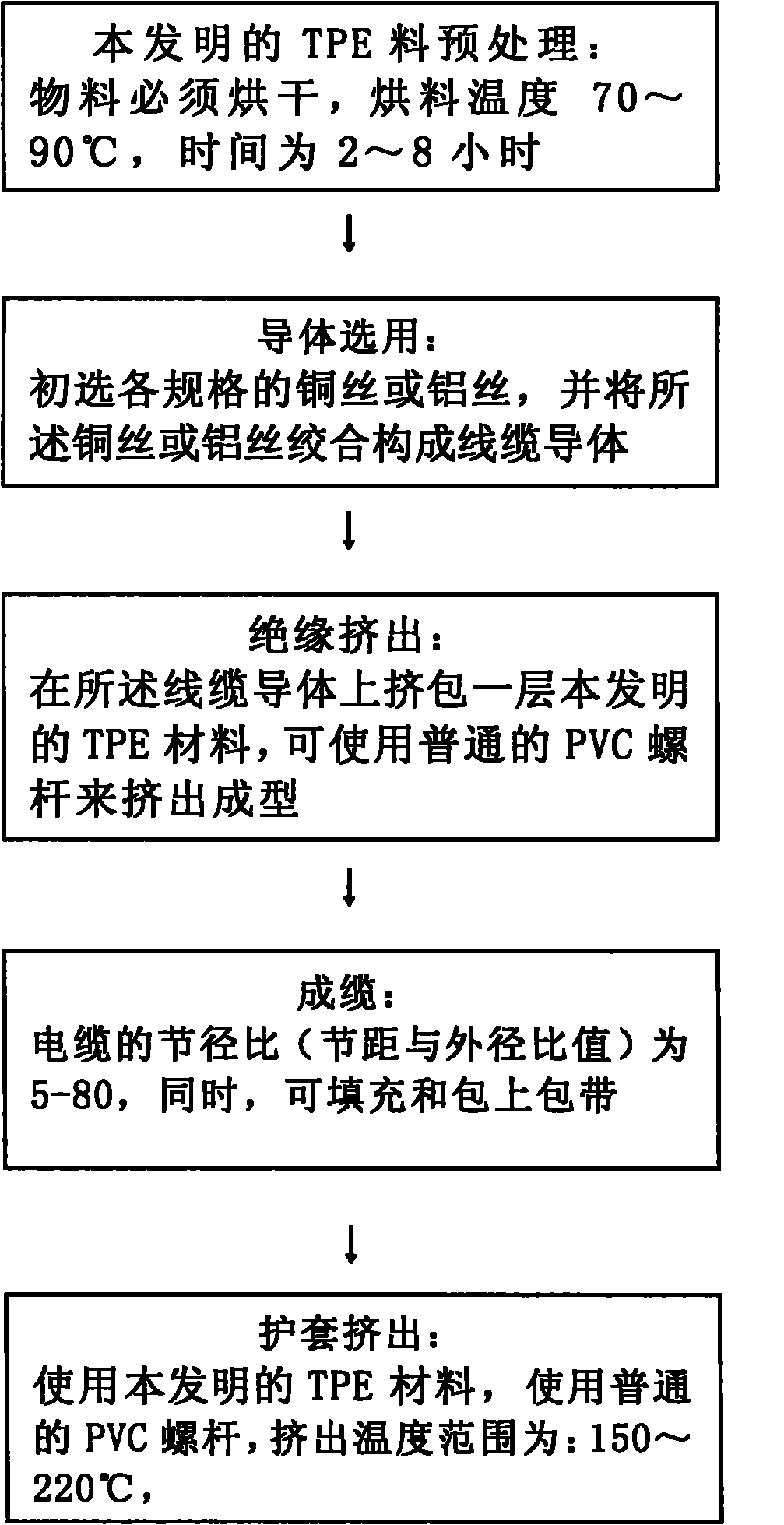

Method used

Image

Examples

Embodiment 1

[0067] Example 1 is suitable for manufacturing environmentally friendly flexible cables; Example 2 is suitable for producing environmentally friendly cables that replace PVC cables; Example 3 is suitable for producing vulcanized rubber-sheathed cables; and Example 4 is suitable for producing environmentally friendly cables that have strict requirements for oil resistance. cable. Thermoplastics PP described in table 1 is polypropylene, and PE is polyethylene, and described EVA resin is ethylene-vinyl acetate copolymer, and described compatibilizer is maleic anhydride grafted SEBS (MSEBS-G-MAH), Maleic anhydride grafted EPDM (MEPDM-G-MAH) or maleic anhydride grafted PP (MPP-G-MAH), the plasticizer is white oil, paraffin oil or dioctyl phthalate, the described Inorganic filler is calcium carbonate (precipitation method) or talcum powder, and the particle diameter of described calcium carbonate or talcum powder exceeds 1250 orders, and described flame retardant is inorganic magnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com