Linear quenching heat exchanger inlet connecting piece and quenching heat exchanger thereof

A quenching heat exchanger and inlet connection technology, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of corrosion cracking, inconvenient maintenance and repair, welding Low strength and other problems, to achieve the effect of easy maintenance and repair, simple structure and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

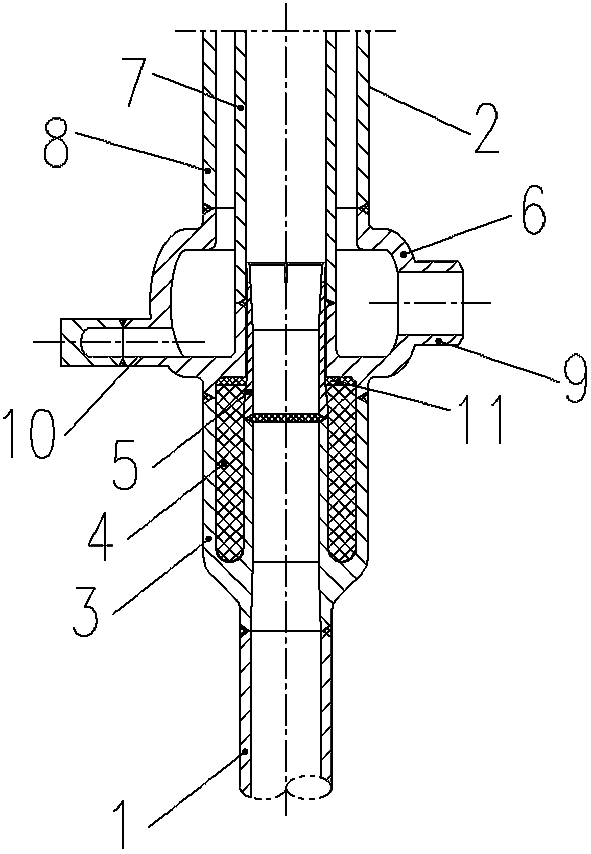

[0025] attached figure 1 It is a linear quenching heat exchanger inlet connector applying the present invention, and is only one form of the present invention, and the present invention is not limited thereto.

[0026] refer to figure 1 , one end of the inlet connector is butt welded with the cracking furnace outlet furnace tube 1, and the other end is butt welded with the double-tube heat exchange element 2. The high-temperature cracked gas enters the linear quenching heat exchanger from the furnace tube 1 at the outlet of the cracking furnace.

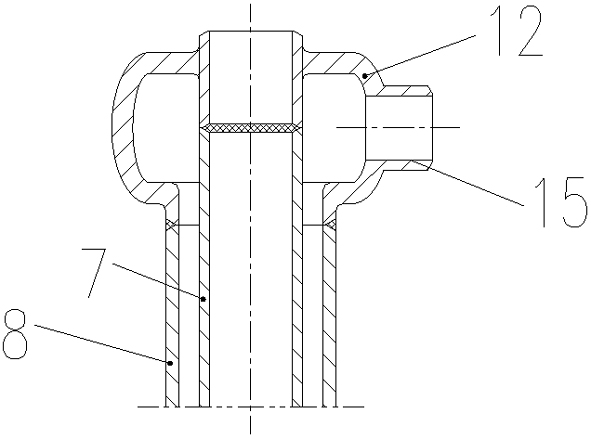

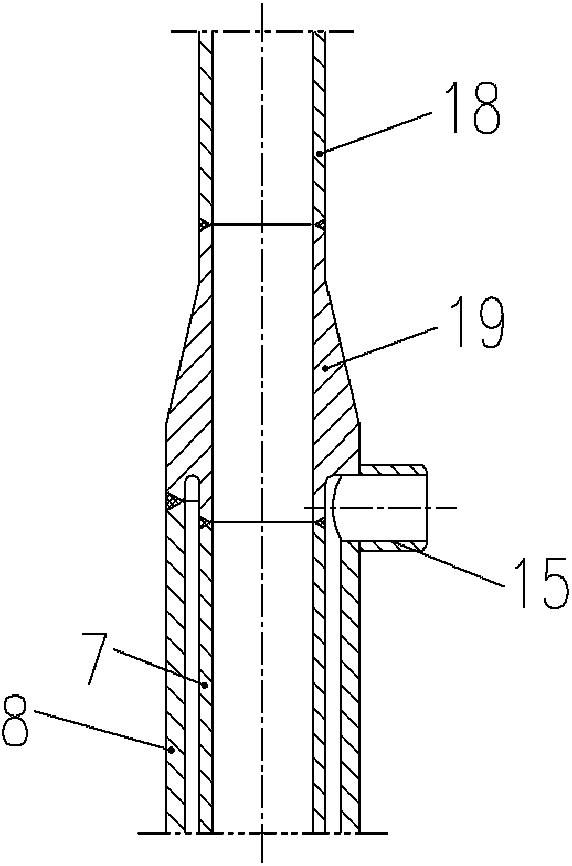

[0027] refer to figure 1 , The inlet connector consists of an inlet cone 3 , an insulator 4 , a seal 11 , a protective sleeve 5 and a cooling medium connector 6 . There is also an inwardly extending boss at the bottom of the cooling medium connecting piece 6, which is connected with the inner tube 7 of the double-tube heat exchange element 2, and the bottom inwardly extending boss and the top of the cooling medium connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com