Selective powder spreading device for selective laser melting forming of large thin-wall part

A technology of laser selective melting and large thin-walled parts, which is applied in the direction of improvement of process efficiency, additive manufacturing, energy efficiency, etc., can solve the problem of high forming cost of additive manufacturing of large thin-walled parts, and achieve the effect of good forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

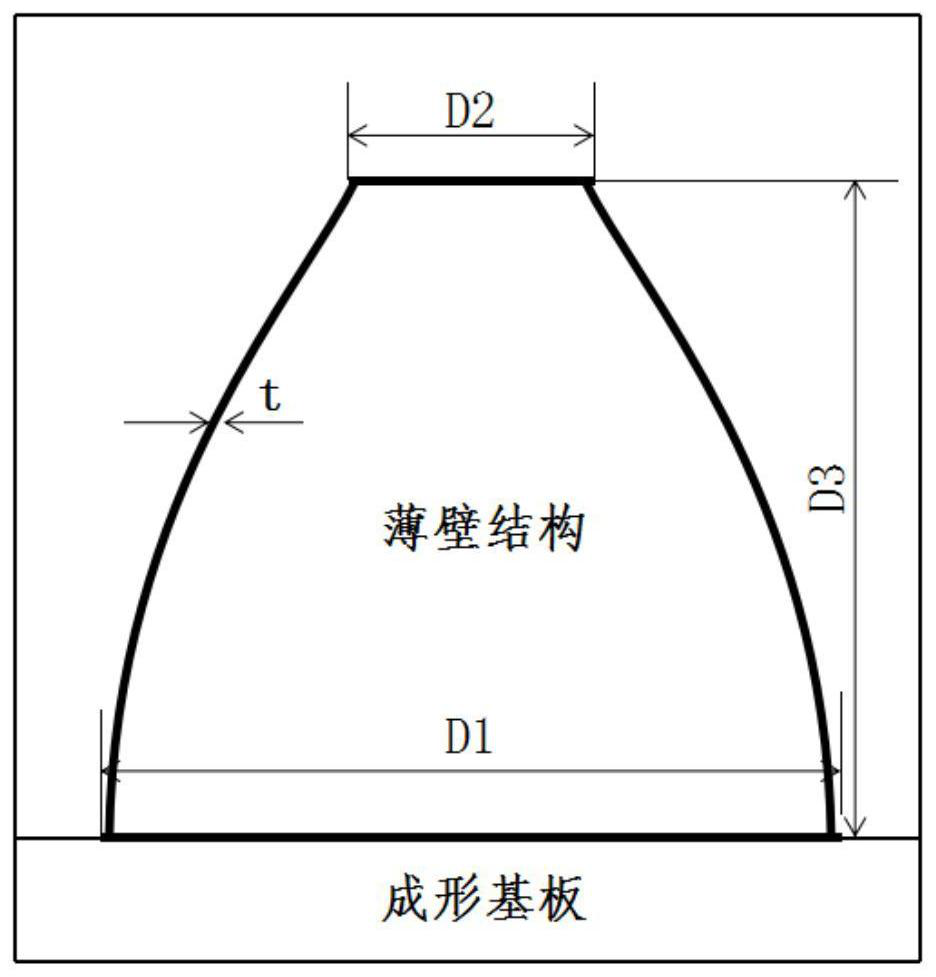

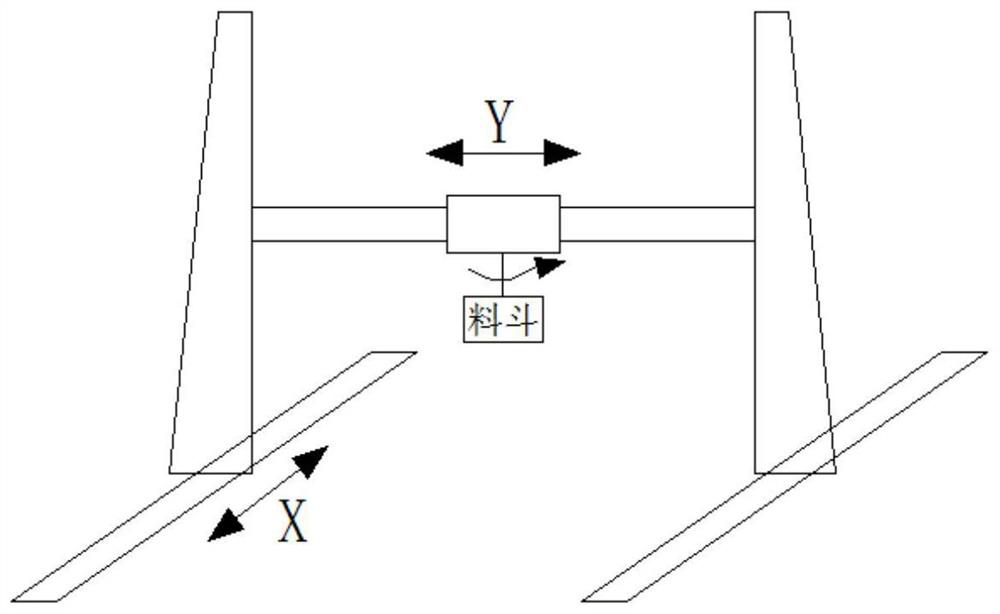

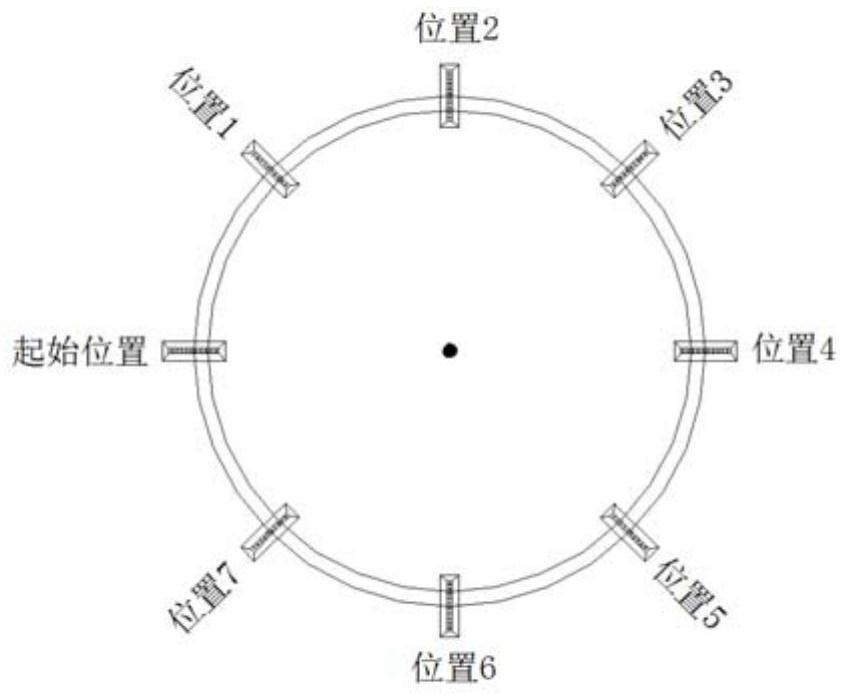

[0029] Taking the large thin-walled part A as an example, the diameter of the large end D1: 900mm, the diameter of the small end D2: 300mm, the shaft height D3 = 800mm, the wall thickness of the thin-walled part A = 5mm, and the width of the powder spreading is D4 = 15mm. The thickness is D6=0.1mm, the number of layers n=D3 / D6=800mm / 0.1mm=8000 layers; compare the data of a single layer of powder that needs to be laid, move the X and Y axes to carry out selective circular powder spreading on the substrate. The width of the first powder spreading is 15mm, the layer thickness is 0.1mm, and the substrate surface is a circle of 445mm, keeping 100 layers; layer; the i-th powdering, the substrate surface is a circle of 450-i*D4mm, and it is kept until the i*100th layer; repeat the above steps, the last powdering, the substrate surface is a circle with a diameter of D=150mm, until the first layer 8000 floors, the structural parts are formed.

example 2

[0031] Taking the large thin-walled part B as an example, the diameter of the large end D1: 1000mm, the diameter of the small end D2: 200mm, the shaft height D3 = 900mm, the wall thickness of the thin-walled part B is t = 8mm, and the powder spreading width is D4 = 16mm. The thickness is D6=0.2mm, the number of layers n=D3 / D6=(1000mm-200mm) / 0.2mm=4000 layers, compared with the single-layer data that needs to lay powder, move the X and Y axes to selectively circularize the substrate Spread the powder. The width of the first powder spreading is 16mm, the layer thickness is 0.2mm, the substrate surface is 484mm circular, and 80 layers are maintained; the second powder spreading width is 16mm, the substrate surface is 468mm circular, and 80 layers are maintained ;For the i-th powder spreading, the width value is 16mm, and the substrate surface is a circle with a diameter of 500-i*D4 mm, and it is maintained until the i*80 layer; repeat the above steps, and the last powder spreadin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com