Composite elastic cushion for multi-point formation

A multi-point forming, elastic pad technology, applied in the field of composite elastic pads, can solve the problems of affecting the accuracy of the forming surface, it is difficult to completely eliminate the concentrated load, etc., and achieve the effect of suppressing the generation of indentation and wrinkles and improving the forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific content and implementation of the present invention will be further described below in conjunction with the embodiments shown in the drawings.

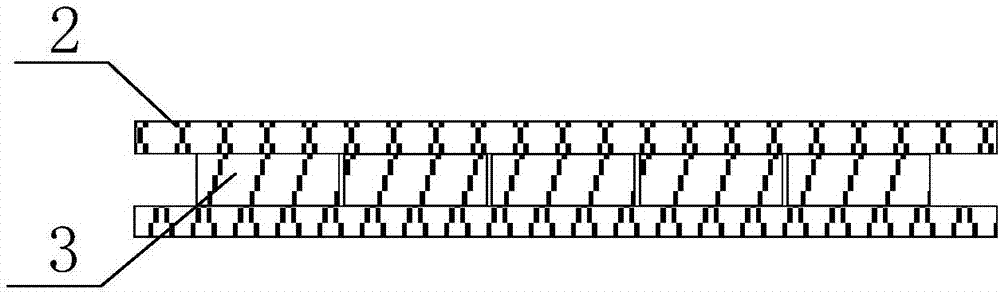

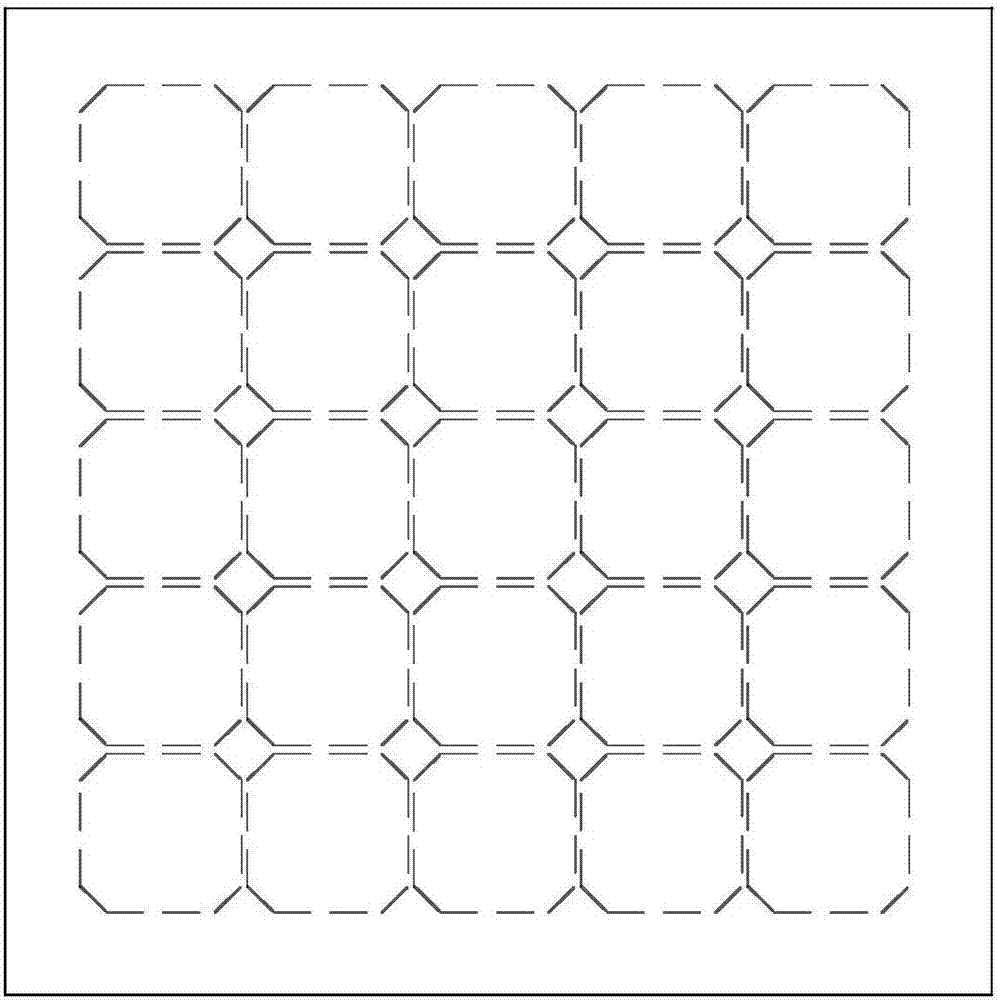

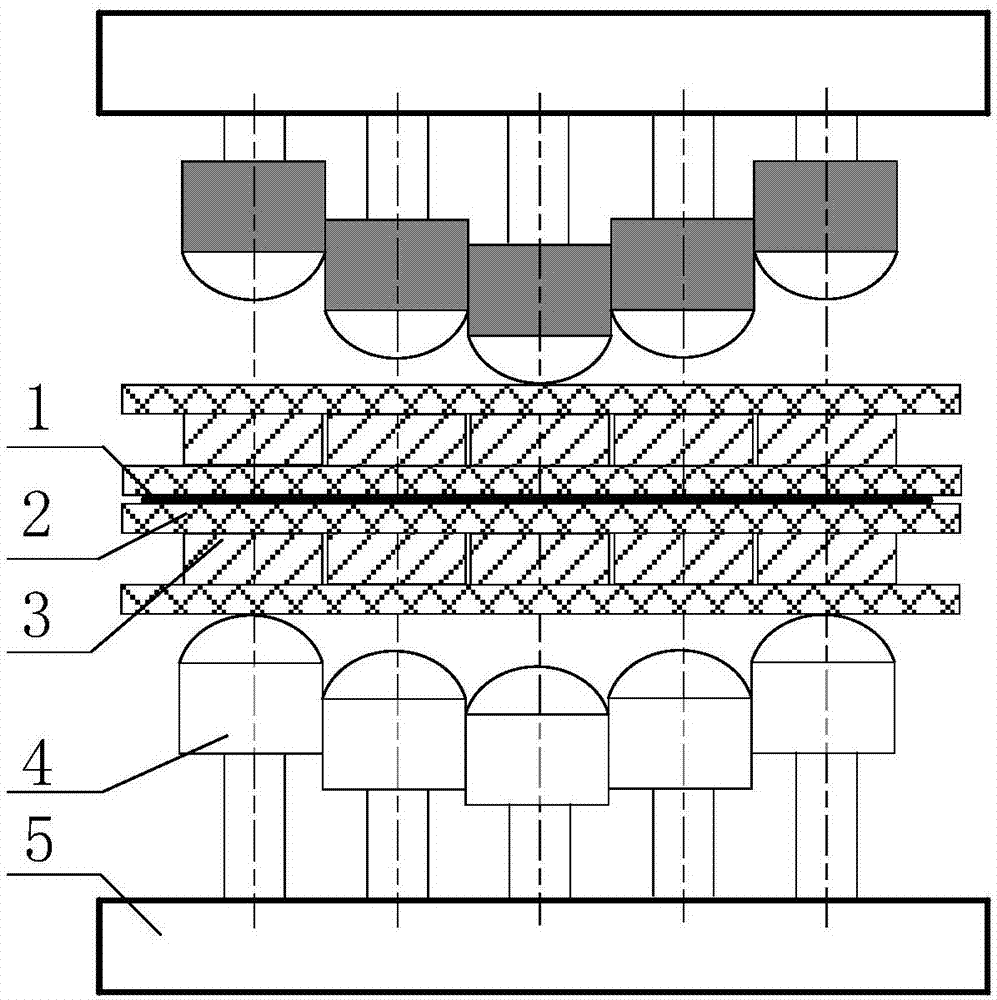

[0025] The composite elastic pad for multi-point forming according to the present invention is mainly composed of a plurality of steel pads 3 and polyurethane pads 2 above and below the steel pads, and the thickness of the polyurethane pads 2 is selected according to the process requirements. A plurality of steel pads can be connected with each other to form a whole. The steel pad is connected to the polyurethane backing plate 2 on its upper and lower sides by gluing. Before forming, the upper and lower basic unit 4 of the multi-point forming device is adjusted to a specified height according to the CAD digital model of the formed part. When forming, the basic body unit 4 of the upper mold moves downward under the drive of the press, compresses the polyurethane backing plate 2 close to the basic body unit side, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com