Method for preparing nano aluminum nitride powder

A nano-aluminum nitride and powder technology, applied in the field of material science, can solve the problems of agglomeration, uneven distribution of components, and inconsistent particle diameter distribution of aluminum nitride powder, and achieve fine particle size, uniform particle distribution, and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

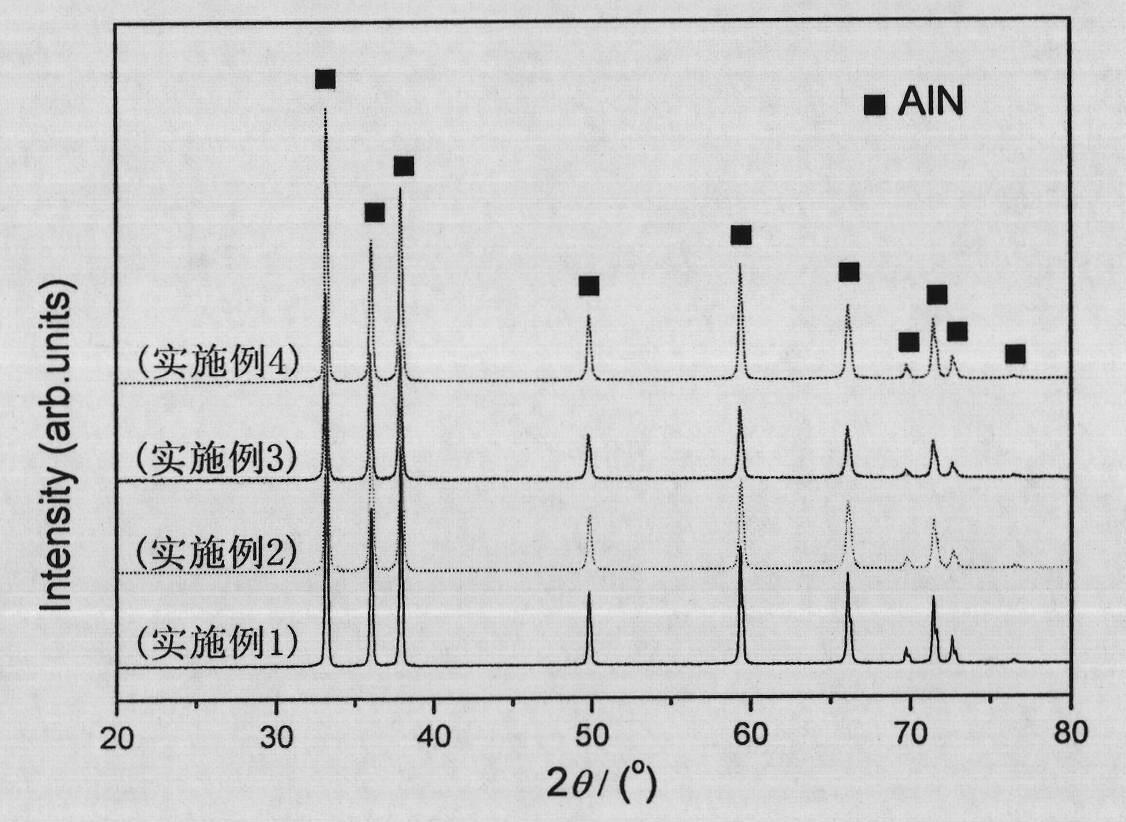

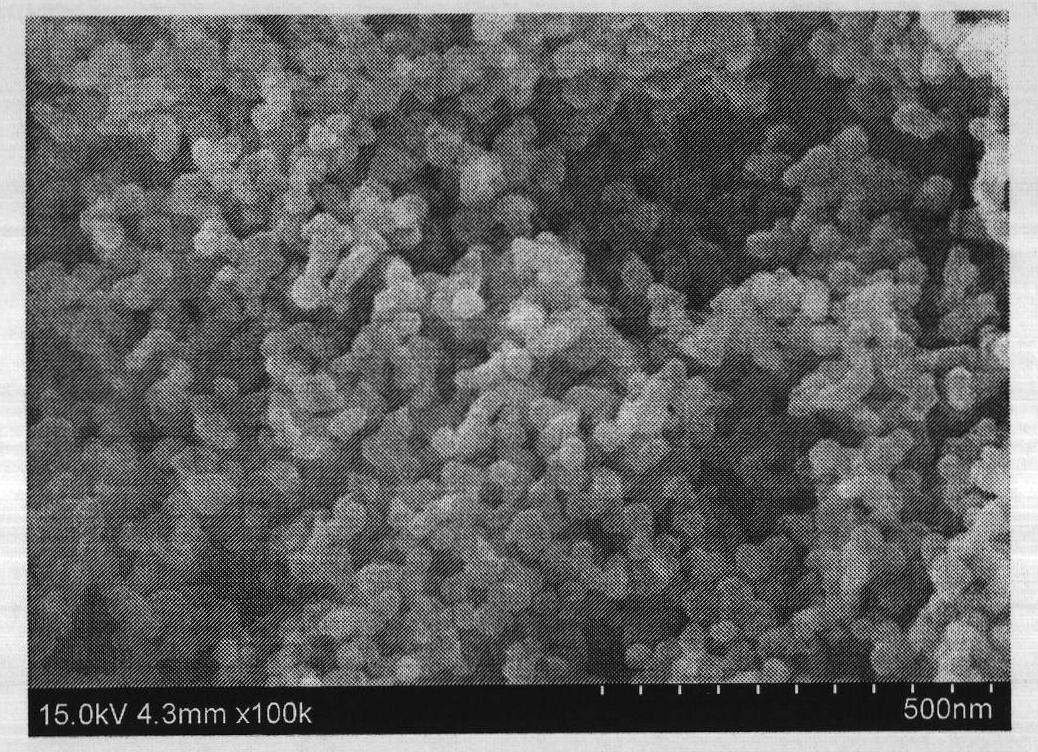

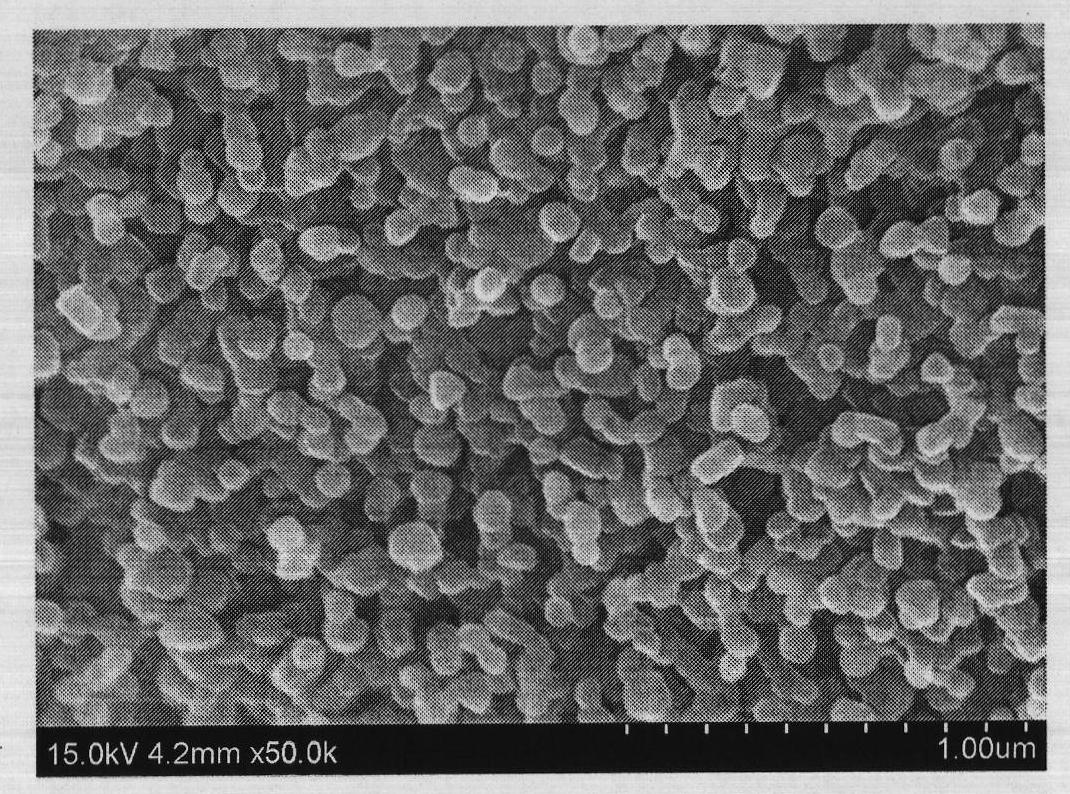

[0022] Weigh 1.0 mol of aluminum nitrate and dissolve in absolute ethanol to form a 4.0 mol / l solution, weigh 0.4 mol of citric acid and dissolve in 1.6 mol of ethylene glycol, mix the above two solutions; dissolve 1.0 mol of glucose in deionized water A 3.0 mol / l solution was formed and then added to the above solution to form a mixed solution. Stir the mixed solution evenly, heat up to 130° C. for 2 hours, and then continue to heat up to 200° C. for 2 hours to obtain a crisp black substance. The above crisp black substance was calcined at 800°C for 1 hour in a nitrogen atmosphere, ground in a mortar after cooling, then placed in a flowing nitrogen atmosphere, and kept at 1450°C for 2 hours to obtain a black powder; The black powder is kept in air at 700°C for 2 hours for decarburization to obtain nano-aluminum nitride powder. The above-mentioned nano-aluminum nitride powder is detected by X-ray diffraction, and the result shows that it is a single AlN phase (see figure 1 )...

Embodiment 2

[0024] Weigh 1.0mol aluminum acetate and dissolve it in acetone to form a 2.0mol / l solution, weigh 1.0mol citric acid and dissolve it in 8.0mol ethylene glycol, and mix the above two solutions; dissolve 0.2mol sucrose in deionized water to form a 2.0mol / l solution. mol / l solution, and then added to the above solution to form a mixed solution. After the mixed solution was stirred evenly, the temperature was raised to 125° C. for 2 hours, and then the temperature was further raised to 190° C. for 3 hours to obtain a crisp black substance. The above-mentioned crisp black substance was calcined in vacuum at 1000°C for 1 hour, ground in a mortar after cooling, then placed in a flowing nitrogen atmosphere, and kept at 1550°C for 3 hours to obtain a black powder; The powder is kept in air at 750°C for 2 hours for decarburization to obtain nano-aluminum nitride powder. The above-mentioned nano-aluminum nitride powder is detected by X-ray diffraction, and the result shows that it is a...

Embodiment 3

[0026] Weigh 1.0mol aluminum isopropoxide and dissolve it in deionized water to form a 1.0mol / l solution, weigh 0.5mol citric acid and dissolve it in 3.0mol ethylene glycol, mix the above two solutions; dissolve 0.25mol methylcellulose Form a 1.0 mol / l solution in absolute ethanol, and then add to the above solution to form a mixed solution. After the mixed solution was stirred evenly, the temperature was raised to 135° C. for 2 hours, and then the temperature was further raised to 220° C. for 2 hours to obtain a crisp black substance. The above crisp black substance was calcined in a nitrogen atmosphere at 1200°C for 1 hour, ground in a mortar after cooling, then placed in a flowing nitrogen atmosphere, and kept at 1400°C for 4 hours to obtain a black powder; The black powder is kept in air at 760°C for 2 hours for decarburization to obtain nano-aluminum nitride powder. The above-mentioned nano-aluminum nitride powder is detected by X-ray diffraction, and the result shows th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com