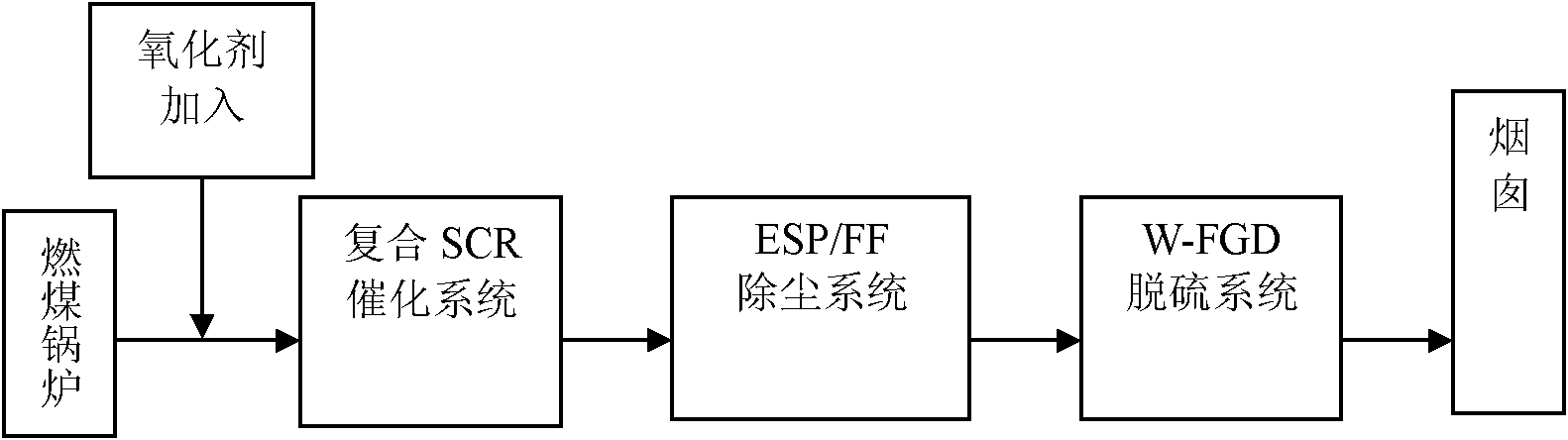

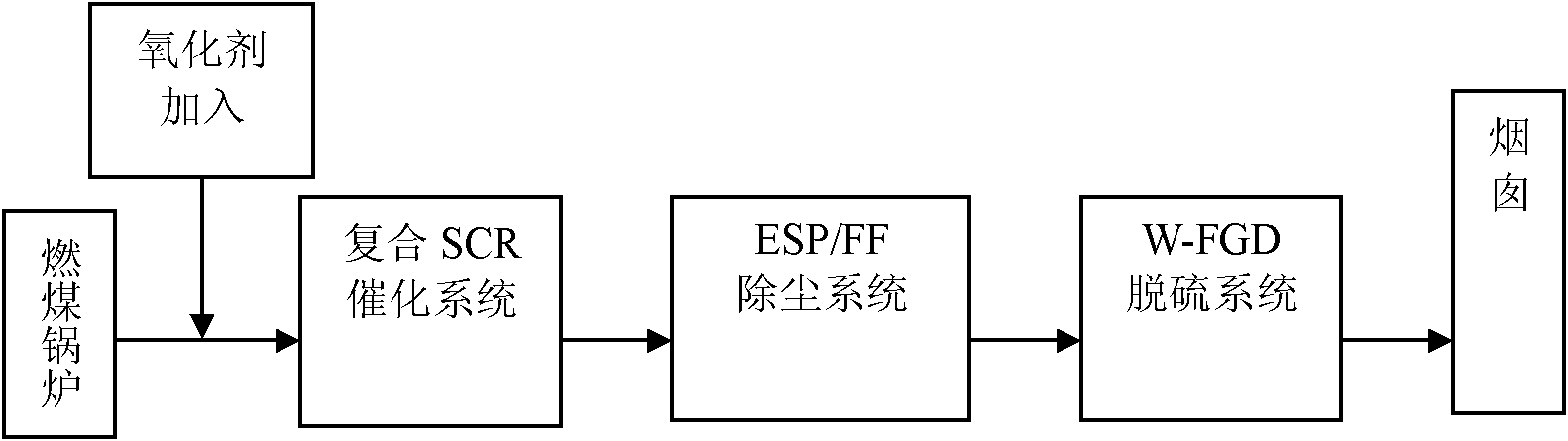

Preparation method of compound SCR catalyst with zero-valent mercury conversion function

A technology of SCR catalyst and zero-valent mercury, which is applied in the field of preparation of composite SCR catalyst, can solve the problems of low oxidation efficiency, affecting catalytic oxidation, and poor catalytic conversion effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] with TiO 2 The SCR catalyst is used as the carrier, and the SCR and Ru / SCR composite catalyst are prepared by impregnation method.

[0022] A. Conventional SCR catalyst preparation impregnation solution composition: 0.3g ammonium metavanadate, 1.8g ammonium tungstate plus deionized water diluted to 20ml, then add 0.5g polyacrylamide as binder;

[0023] B. Composition of impregnating solution prepared by conventional SCR catalyst: 0.3g ammonium metavanadate, 1.8g ammonium paramolybdate, dilute to 20ml with deionized water, then add 0.5g polyacrylamide as binder;

[0024] C, ruthenium-doped SCR composite catalyst preparation impregnation solution composition: 0.2g ruthenium chloride, 0.3g ammonium metavanadate, 1.8g ammonium tungstate plus deionized water diluted to 20ml, then add 0.5g polyacrylamide as a binder;

[0025] Using powdered TiO 2 As a catalyst carrier, weigh 3 parts, 30g each; pour them into the above three solutions for immersion and stir, pour out the exc...

Embodiment 2

[0030] with TiO 2 The SCR catalyst is used as the carrier, and the ruthenium-doped modified molybdenum-containing SCR composite catalyst is prepared by impregnation method.

[0031]Preparation of impregnation solution with ruthenium-doped SCR composite catalyst composition: 0.2g ruthenium chloride, 0.3g ammonium metavanadate, 1.8g ammonium paramolybdate, add deionized water to dilute to 20ml, then add 0.5g polyacrylamide as binder;

[0032] Weigh 30g powdered TiO 2 As a catalyst carrier, pour it into the above-mentioned precursor solution for impregnation and stir, pour out the excess impregnation solution after soaking for 1 hour, and dry the impregnated powder in an oven at 60-70°C, and then Pour them into the remaining impregnating solution respectively, and stir well, so that the impregnating solution is completely covered with TiO 2 Carrier blotted dry.

[0033] The impregnated SCR is then dried at a temperature of 60-80°C for 4-6 hours, then transferred to a muffle fu...

Embodiment 3

[0037] Based on the finished commercial V / W / Ti type SCR catalyst, it is ground into 40-60 mesh particles, and then modified by ruthenium doping, and the Ru / SCR catalyst is prepared by impregnation method.

[0038] Prepare impregnation solution: A: 0.2g ruthenium chloride and deionized water to dilute to 20ml; B: 0.2g ruthenium chloride, 0.5g ammonium paramolybdate and deionized water to dilute to 20ml.

[0039] Using powdered SCR as the catalyst carrier, weigh 2 parts, 30g each; pour them into the above two solutions for immersion and stir, pour out the excess immersion solution after immersion for 1 hour, and pour out the SCR after immersion once. The powder is dried in an oven at 60-70°C, and then poured into the remaining impregnating solution respectively, and fully stirred, so that the impregnating solution is completely absorbed by the SCR carrier.

[0040] The impregnated SCR is then dried at a temperature of 60-80°C for 4-6 hours, then transferred to a muffle furnace a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com