Double-layer anti-reflective film for crystalline silicon solar battery and preparation method thereof

A technology of solar cells and anti-reflection coatings, which is applied to circuits, electrical components, semiconductor devices, etc., can solve problems such as low reflectivity and difficulty in achieving anti-reflection effects with a single-layer anti-reflection coating, and achieve simple equipment and improved photoelectric conversion Efficiency, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

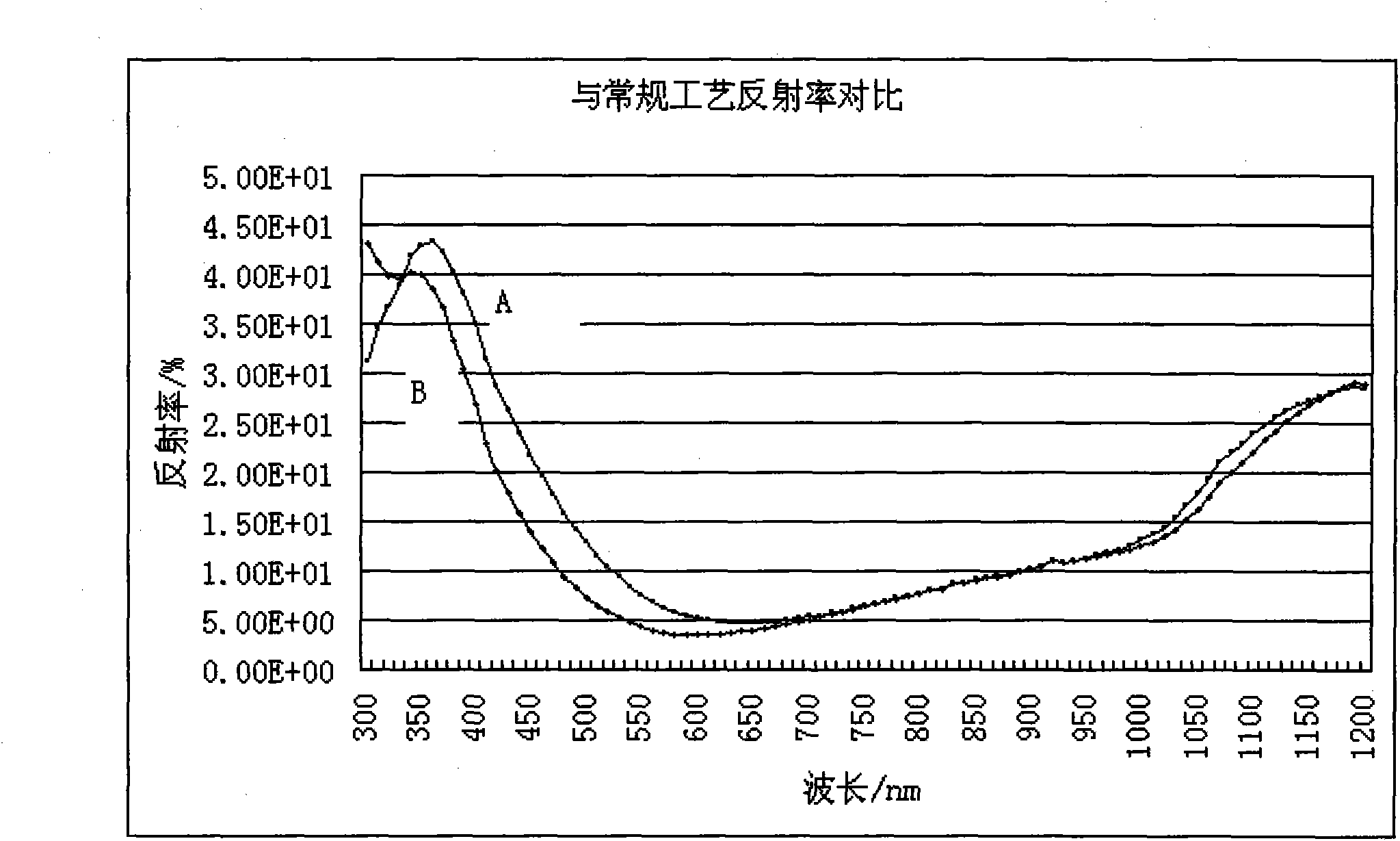

Embodiment 1

[0034] A method for preparing a double-layer anti-reflection film for a crystalline silicon solar cell, comprising the following steps: according to the conventional treatment method of the battery, the silicon wafer is cleaned and textured, diffused to prepare a PN junction, and the silicon wafer is etched and removed. PN junction, cleaning to remove phospho-silicate glass, and then include the following steps:

[0035] The first step: grow a layer of SiO on the surface of the silicon wafer by thermal oxidation method 2 thin film, reactive gas N 2 10L / min, O 2 The process temperature is 15L / min, the process temperature is 880°C, and the time is 20min to form a layer of SiO with a refractive index of 1.46 and a thickness of 10nm. 2 film;

[0036] Step 2: Take a certain amount of n-butyl titanate and slowly add it dropwise into n-butanol, the solution concentration is 0.5mol / L, stir the solution for 0.5h with a magnetic stirrer, then add 1~3mL distilled water dropwise , sti...

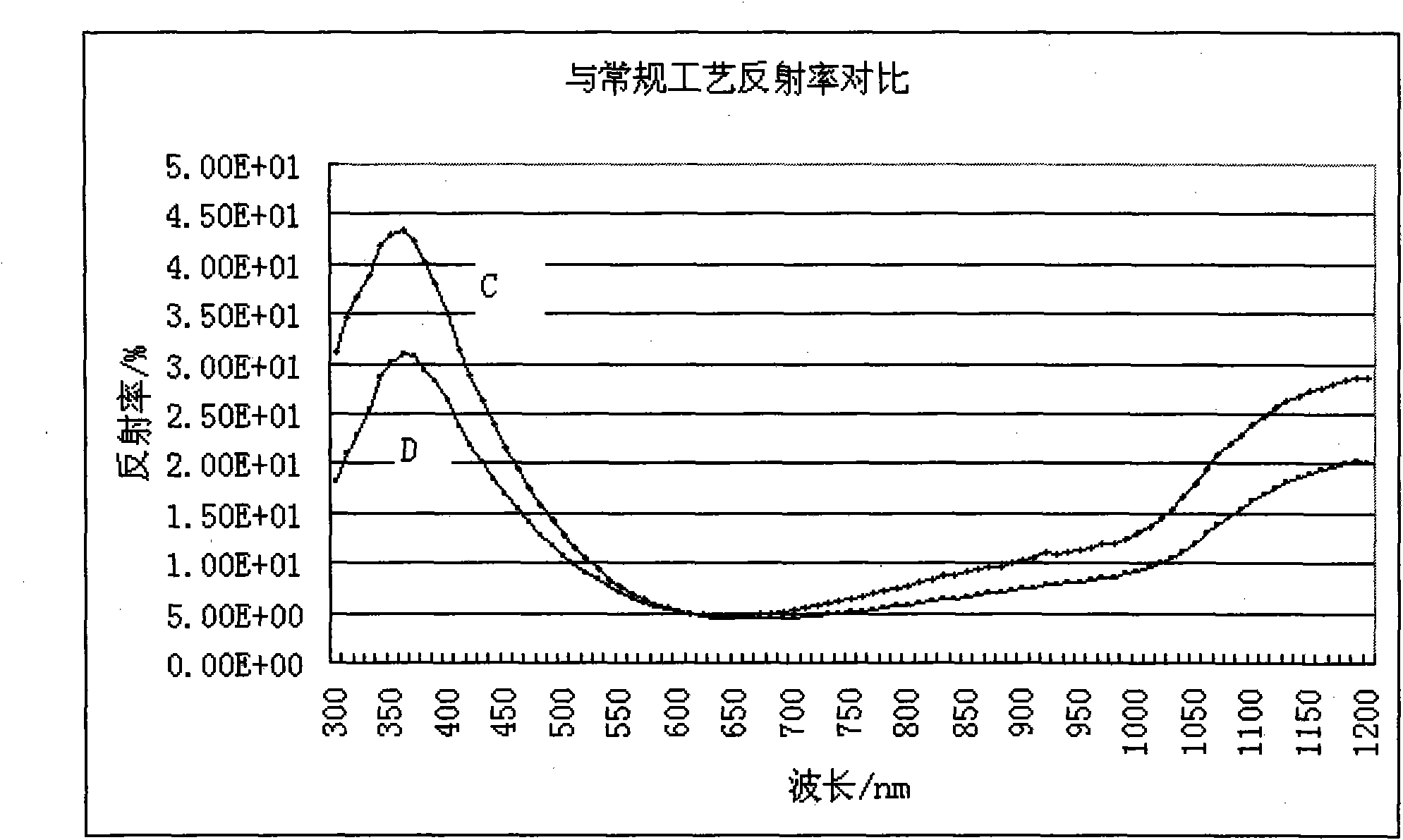

Embodiment 2

[0045]A method for preparing a double-layer anti-reflection film for a crystalline silicon solar cell, comprising the following steps: according to the conventional treatment method of the battery, the silicon wafer is cleaned and textured, diffused to prepare a PN junction, and the silicon wafer is etched and removed. PN junction, cleaning to remove phospho-silicate glass, and then include the following steps:

[0046] The first step: grow a layer of SiO on the surface of the silicon wafer by thermal oxidation method 2 thin film, reactive gas N 2 20L / min, O 2 The process temperature is 30L / min, the process temperature is 880°C, and the time is 40min to form a layer of SiO with a refractive index of 1.46 and a thickness of 20nm. 2 film;

[0047] Step 2: Take a certain amount of isopropyl titanate and slowly add it dropwise into isopropanol. The concentration of the solution is 0.4mol / L. After stirring the solution for 0.5h with a magnetic stirrer, add 1~3mL of distilled wat...

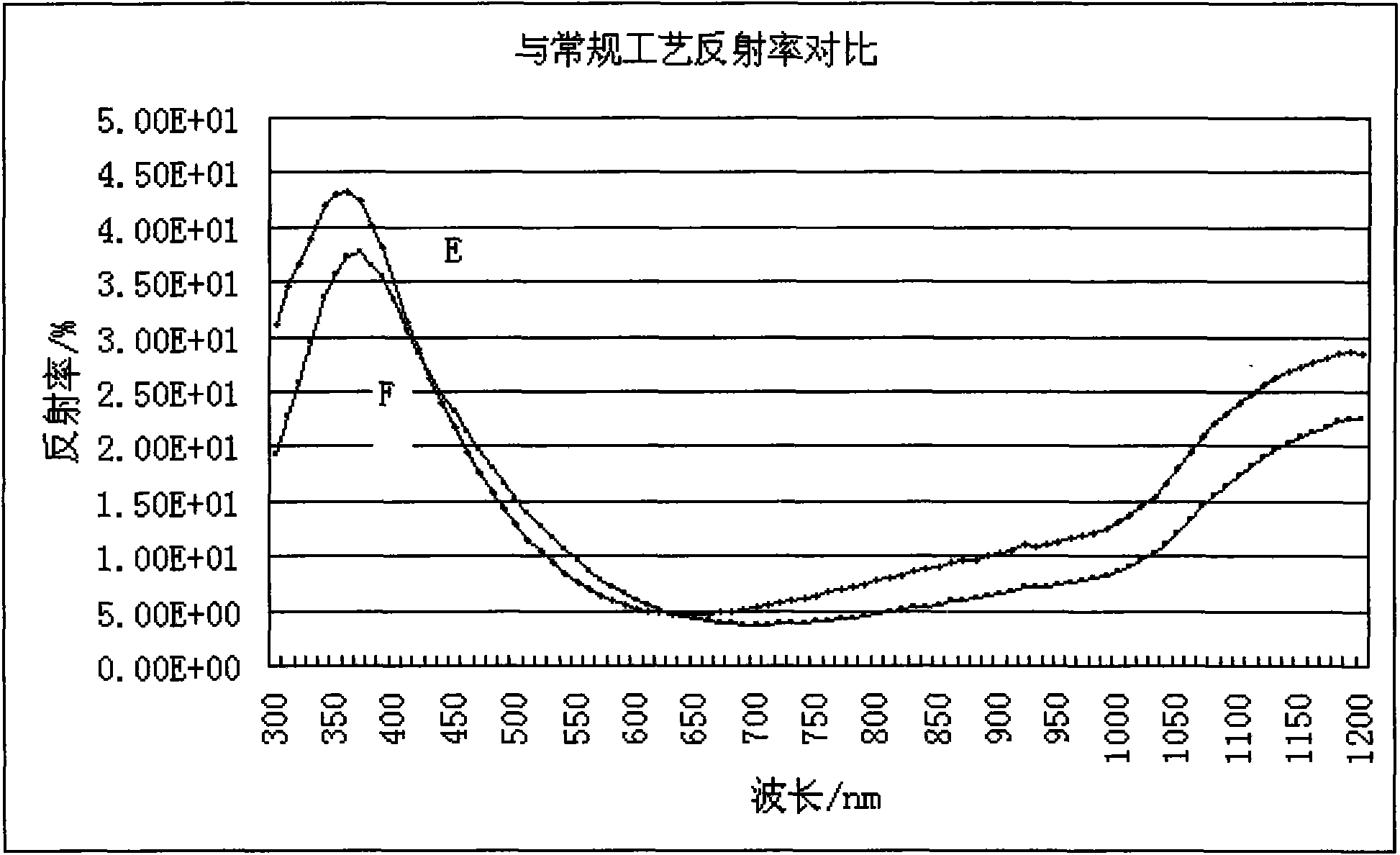

Embodiment 3

[0054] A method for preparing a double-layer anti-reflection film for a crystalline silicon solar cell, comprising the following steps: according to the conventional treatment method of the battery, the silicon wafer is cleaned and textured, diffused to prepare a PN junction, and the silicon wafer is etched and removed. PN junction, cleaning to remove phospho-silicate glass, and then include the following steps:

[0055] The first step: grow a layer of SiO on the surface of the silicon wafer by thermal oxidation method 2 thin film, reactive gas N 2 30L / min, O 2 The process temperature is 30L / min, the process temperature is 840°C, and the time is 60min to form a layer of SiO with a refractive index of 1.46 and a thickness of 20nm. 2 film;

[0056] Step 2: Take a certain amount of titanium tetrachloride and slowly add it dropwise into absolute ethanol, the solution concentration is 0.3mol / L, stir the solution for 0.5h with a magnetic stirrer, then add 1-3mL distilled water dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com