Process for intensifying ultrasonic vibration assisted electric spark pulse discharging surface

A technology of ultrasonic vibration and surface strengthening, which is applied in the field of surface treatment of materials, and can solve problems such as limited application and uneven distribution of strengthening layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

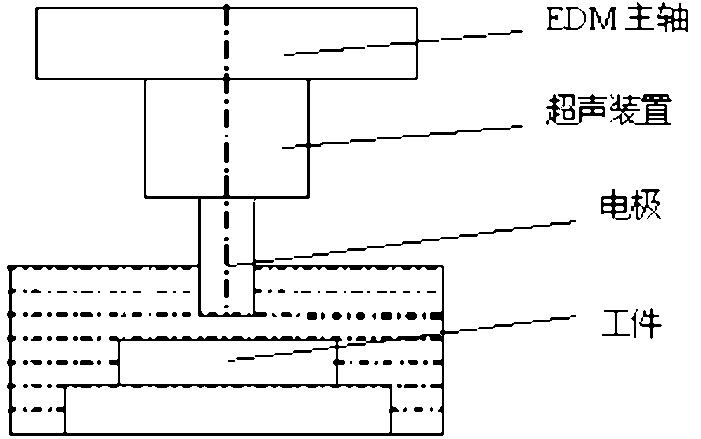

Embodiment 1

[0022] The workpiece electrode is 65Mn steel tempered at medium temperature after quenching, and its original structure is tempered troostite, with a size of 100mm×12mm×0.5mm. The tool electrode is made of single crystal Si with a content of 99.999%, and the size is 12mm×12mm×20mm. The experimental machine tool is Beijing AgieCharmilles SF201 electric discharge precision forming machine tool, and the positive polarity electric spark surface strengthening is carried out on 65Mn steel in kerosene. The tool electrode is installed at the end of the ultrasonic horn of the ultrasonic generator, and is closely combined with the horn to ensure that it can resonate with the vibration frequency of the ultrasonic transducer. The ultrasonic generator, ultrasonic transducer, horn, and tool electrode form a mechanical resonance system. The ultrasonic transducer, horn and tool electrode are combined to form an ultrasonic vibration device installed on the spindle of the precision electric di...

Embodiment 2

[0024] The workpiece electrode is 65Mn steel tempered at medium temperature after quenching, and its original structure is tempered troostite, with a size of 100mm×12mm×0.5mm. The tool electrode is made of single crystal Si with a content of 99.999%, and the size is 12mm×12mm×20mm. The experimental machine tool is Beijing AgieCharmilles SF201 electric discharge precision forming machine tool, and the positive polarity electric spark surface strengthening is carried out on 65Mn steel in kerosene. The tool electrode is installed at the end of the ultrasonic horn of the ultrasonic generator, and is closely combined with the horn to ensure that it can resonate with the vibration frequency of the ultrasonic transducer. The ultrasonic generator, ultrasonic transducer, horn, and tool electrode form a mechanical resonance system. The ultrasonic transducer, horn and tool electrode are combined to form an ultrasonic vibration device installed on the spindle of the precision electric di...

Embodiment 3

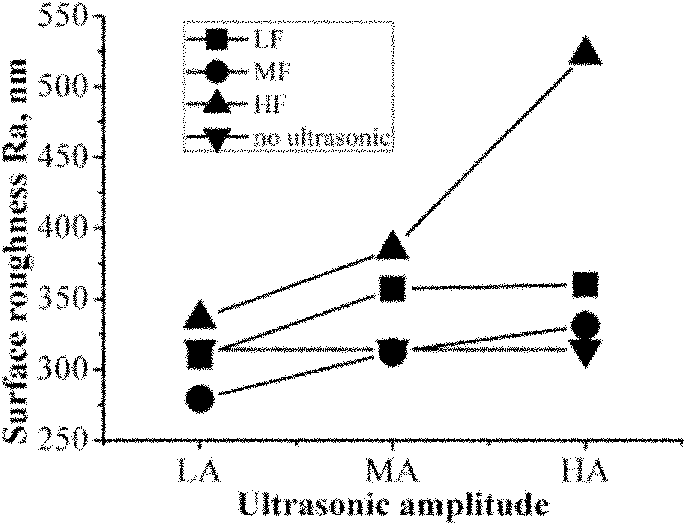

[0026] The electric discharge machine tool is the SF201 precision electric discharge forming machine produced by Beijing AgieCharmilles. The ultrasonic generator is manufactured by Shanghai Ultrasonic Equipment Factory. The maximum output power is 150W and the maximum amplitude is 12μm. It can realize the output power and frequency. manual adjustment. The workpiece is made of 65Mn steel quenched and tempered at medium temperature, and the size is 100mm×12mm×0.5mm. The tool electrode is made of single crystal Si with a content of 99.999%, and the size is 12mm×12mm×20mm. The electrical parameters were set as follows: positive polarity processing, pulse width 4.2μs, pulse interval 18μs, peak current 5.6A, strengthening time 15min. The tool electrode is installed at the end of the ultrasonic horn and is closely combined with the horn to ensure that it can resonate with the vibration frequency of the ultrasonic transducer. The ultrasonic generator, ultrasonic transducer, horn and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com