Pure acrylic emulsion modified by inorganic nanoparticles and preparation method thereof

A technology of inorganic nanoparticles and pure acrylic emulsion, applied in the direction of coating, etc., can solve the problems of small particle size of inorganic nanoparticles, low dispersion compatibility, reduced mechanical properties of nanocomposites, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Raw material formula:

[0016] Deionized water 45%;

[0017] Methyl methacrylate 24%;

[0018] Butyl Acrylate 25%;

[0019] Methacrylic acid 0.8%;

[0020] Compound emulsifier 2.6%;

[0021] Potassium persulfate 0.5%;

[0022] Silane coupling agent and oleic acid mixture 0.04%

[0023] Nano-TiO 2 0.66%;

[0024] Sodium bicarbonate 0.4%;

[0025] Ammonia 1.0%.

[0026] 2. Preparation method:

[0027] Nano TiO 2 Add methyl methacrylate, butyl acrylate, and methacrylic acid monomers into a beaker and stir vigorously for 2 hours, then sonicate for 2 hours. Stir the compound emulsifier, deionized water, and sodium bicarbonate in a three-necked flask, and heat it in a water bath. When the temperature rises to 50°C, add 0.1% potassium persulfate; when the temperature rises to 82°C, start adding TiO 2 The monomer mixture and add the remaining 0.4% potassium persulfate at the same time, ensure that the dropwise addition ends in about 2.5 hours and...

Embodiment 2

[0031] 1. Raw material formula:

[0032] Deionized water 58%;

[0033] Methyl methacrylate 20%;

[0034] Butyl Acrylate 16%;

[0035] Methacrylic acid 1.2%;

[0036] Compound emulsifier 2.9%;

[0037] Potassium persulfate 0.4%;

[0038] Silane coupling agent and oleic acid mixture 0.17%;

[0039] Nano-TiO 2 0.23%;

[0040] Sodium bicarbonate 0.6%;

[0041] Ammonia 0.5%.

[0042] 2. Preparation method:

[0043] The preparation method is the same as in Example 1.

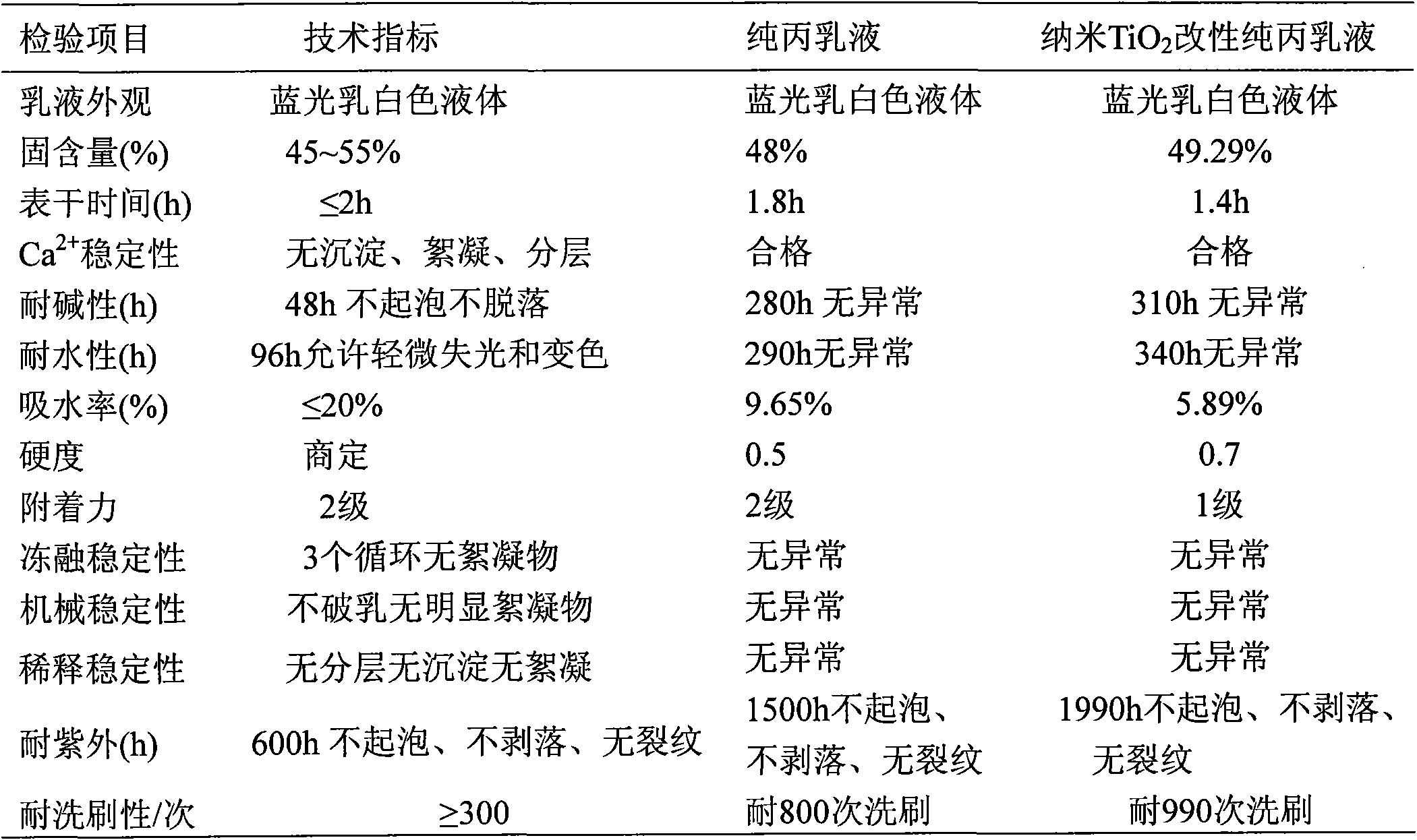

[0044] Three, the inorganic nano-TiO obtained in the present embodiment 2 Performance comparison table of modified pure acrylic emulsion and pure acrylic emulsion:

[0045]

Embodiment 3

[0047] 1. Raw material formula:

[0048] Deionized water 45%;

[0049] Methyl methacrylate 30%;

[0050] Butyl Acrylate 18%;

[0051] Methacrylic acid 1.2%;

[0052] Compound emulsifier 3.4%;

[0053] Potassium persulfate 0.6%;

[0054] Silane coupling agent and oleic acid mixture 0.15%;

[0055] Nano-TiO 2 0.55%;

[0056] Sodium bicarbonate 0.5%;

[0057] Ammonia 0.7%.

[0058]2. Preparation method:

[0059] The preparation method is the same as in Example 1.

[0060] Three, the inorganic nano-TiO obtained in the present embodiment 2 Performance comparison table of modified pure acrylic emulsion and pure acrylic emulsion:

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com