Method for preparing silicon carbide bullet-proof ceramics

A technology of silicon carbide and silicon carbide powder, which is applied in the field of silicon carbide bulletproof ceramics, can solve the problems that the protection coefficient cannot be achieved, and the cost is only one tenth of that of boron carbide ceramics, and achieve high elastic modulus and high hardness , the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

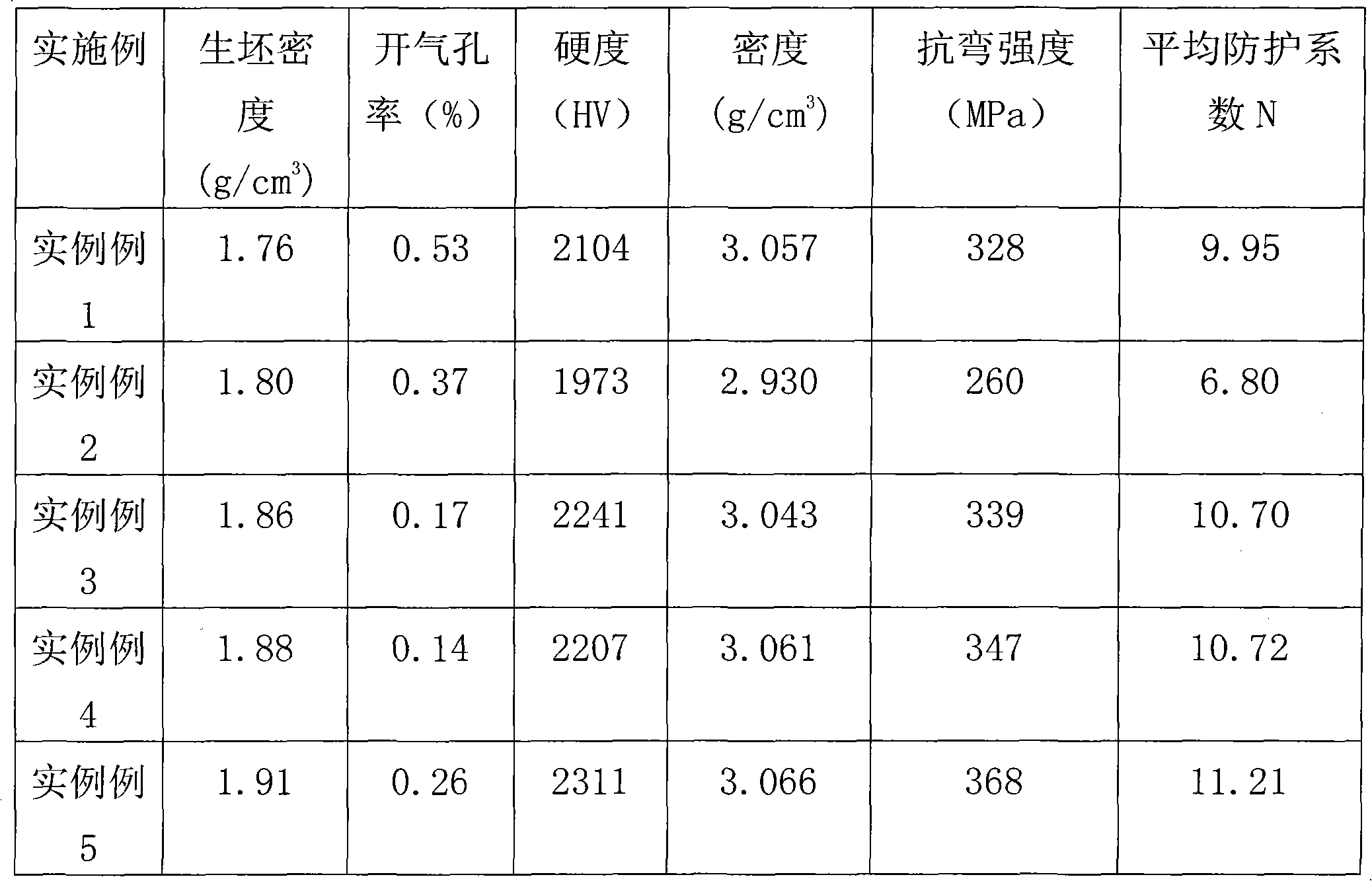

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] Step 1: Put 40 parts of silicon carbide powder, 10 parts of nano-carbon black, and 12 parts of phenolic resin into a ball mill for wet mixing by weight, and the particle size of the above-mentioned silicon carbide powder is d 50 10 μm, the purity of silicon carbide is 99%, the nano-carbon black is N330 carbon black, the phenolic resin is 2130 resin, and the solid content is 83%;

[0022] Step 2: After drying the powder mixed in step 1 at room temperature, add 400ml of absolute ethanol per kilogram according to the powder mass, and stir and dry at 40°C until the absolute ethanol in the powder evaporates to Accounting for 3% of the total mass of the mixed powder, then granulate the mixed powder and pass through a 20-mesh sieve to make the particle size uniform;

[0023] Step 3. Select a mold according to the shape of the desired product, evenly distribute the above-mentioned powder in the cavity of the mold, and pres...

Embodiment 2

[0027] This embodiment includes the following steps:

[0028] Step 1: Put 50 parts of silicon carbide powder, 8 parts of nano-carbon black, and 3 parts of phenolic resin into a ball mill for wet mixing by weight. The particle size of the above-mentioned silicon carbide powder is 30 μm, and the purity of silicon carbide is greater than 98%. Carbon black is N330 carbon black, and described phenolic resin is 2130 resin, and solid content is 88%;

[0029] Step 2: After drying the powder mixed in step 1 at room temperature, add 600ml of absolute ethanol per kilogram according to the powder mass, and stir and dry at 80°C until the absolute ethanol in the powder volatilizes to It accounts for 10% of the total mass of the mixed powder, and then the mixed powder is granulated and passed through a 400-mesh sieve to make the particle size uniform;

[0030] Step 3: Select a mold according to the shape of the desired product, evenly distribute the above-mentioned powder in the cavity of t...

Embodiment 3

[0034] This embodiment includes the following steps:

[0035] Step 1: Put 42 parts of silicon carbide powder, 10 parts of nano-carbon black, and 6 parts of phenolic resin into a ball mill for wet mixing by weight. The particle size of the above-mentioned silicon carbide powder is 14 μm, and the purity of silicon carbide is greater than 98%. Carbon black is N330 carbon black, and the phenolic resin is 2130 resin with a solid content of 83% to 88%;

[0036] Step 2: After drying the powder mixed in step 1 at room temperature, add 500ml of absolute ethanol per kilogram according to the powder mass, and stir and dry at 60°C until the absolute ethanol in the powder evaporates to Accounting for 5% of the total mass of the mixed powder, the mixed powder is then granulated and passed through a 180-mesh sieve to make the particle size uniform;

[0037] Step 3: Select a mold according to the shape of the desired product, evenly distribute the above-mentioned powder in the cavity of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com