Micro-nano composite zinc oxide slurry and preparation method and application thereof

A micro-nano composite, zinc oxide technology, applied in the direction of photosensitive equipment, semiconductor/solid-state device manufacturing, electrolytic capacitors, etc., can solve the problems of insufficient strength of ZnO photoanode film, complicated methods, etc. Simple, improved connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

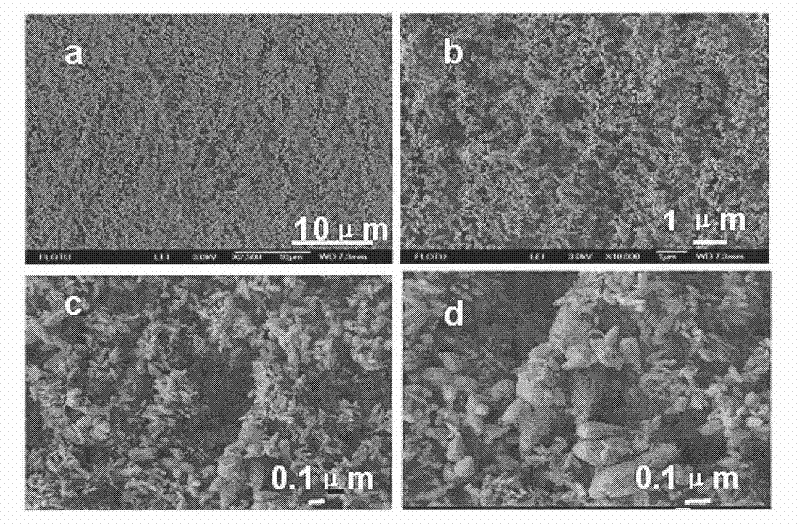

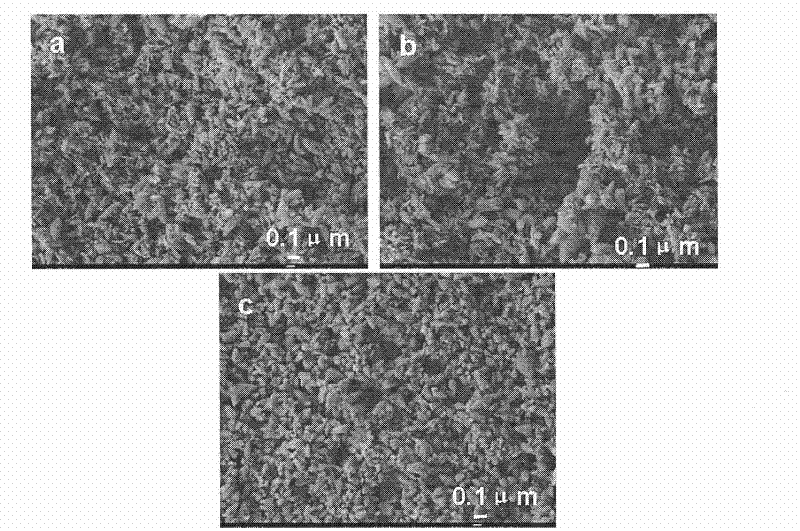

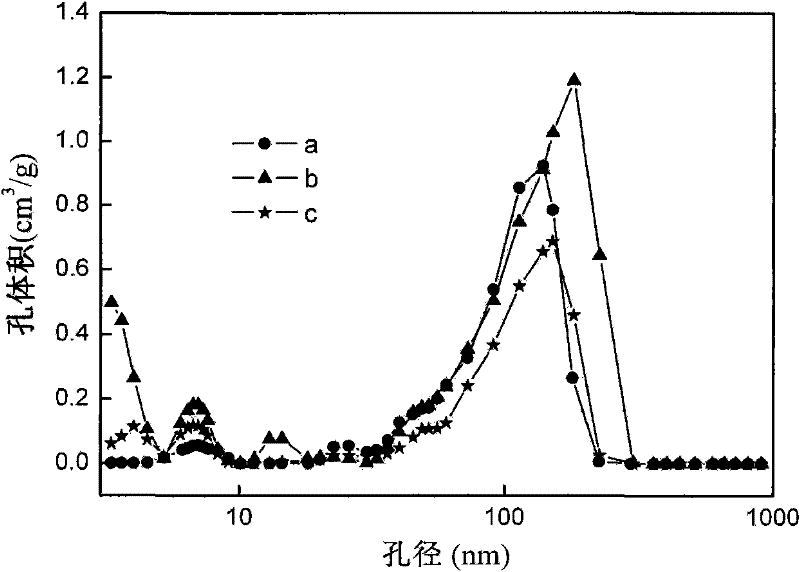

Embodiment 1

[0044] Place the Erlenmeyer flask with 250ml of deionized water in a water bath at 80°C, then add 1g of cetyltrimethylammonium bromide (CTAB) to the deionized water; after 30 minutes, the surfactant is completely dissolved , after the temperature is constant, add 5ml of ammonium hydroxide (NH 3 content between 25.0%-28.0%), mechanically stirred for 10 minutes; weighed 1.8 grams of zinc acetate dihydrate, dissolved in 15ml of deionized water, and then added to the Erlenmeyer flask, at this time there was Zn(OH) 2 A white precipitate is formed, and the reaction is carried out for 1 hour; take the Erlenmeyer flask out of the water bath, cool to room temperature, then filter the precipitate with a glass sand funnel, wash the precipitate with absolute ethanol for 3 times, and put it into a watch glass. Ethanol remaining in the sample was evaporated as much as possible. Weigh the quality of the product, then add a certain amount of ethanol according to the ratio of 1g solid: 1.4ml ...

Embodiment 2

[0046] Place the Erlenmeyer flask with 500ml of deionized water in a water bath at 80°C, then add 1 gram of cetyltrimethylammonium bromide (CTAB) to the deionized water; after 30 minutes, the surfactant is completely Dissolve, after the temperature is constant, add 5ml ammonium hydroxide (NH 3content between 25.0%-28.0%), mechanically stirred for 10 minutes; weighed 1.8 grams of zinc acetate dihydrate, dissolved in 15ml of deionized water, and then added to the Erlenmeyer flask, at this time there was Zn(OH) 2 White precipitate The reaction was carried out for 1 hour; the Erlenmeyer flask was taken out from the water bath, cooled to room temperature, and then the precipitate was filtered out with a glass sand funnel. Ethanol remaining in the sample was evaporated. Weigh the quality of the product, then add a certain amount of ethanol according to the ratio of 1g solid: 1.4ml ethanol, mix and disperse under the conditions of ultrasonic vibration and vortex vibration, the frequ...

Embodiment 3

[0048] Place the Erlenmeyer flask with 1000ml of deionized water in a water bath at 80°C, then add 1 gram of cetyltrimethylammonium bromide (CTAB) to the deionized water; after 30 minutes, the surfactant is completely Dissolve, after the temperature is constant, add 5ml ammonium hydroxide (NH 3 content between 25.0%-28.0%), mechanically stirred for 10 minutes; weighed 1.8 grams of zinc acetate dihydrate, dissolved in 15ml of deionized water, and then added to the Erlenmeyer flask, at this time there was Zn(OH) 2 White precipitate The reaction was carried out for 1 hour; the Erlenmeyer flask was taken out from the water bath, cooled to room temperature, and then the precipitate was filtered out with a glass sand funnel. Ethanol remaining in the sample was evaporated. Weigh the quality of the product, then add a certain amount of ethanol according to the ratio of 1g solid: 1.4ml ethanol, mix and disperse under the conditions of ultrasonic oscillation and vortex oscillation, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com