Super-strength sucker rod steel

An ultra-high-strength sucker rod steel technology, applied in the field of alloy steel materials, can solve problems such as corrosion fatigue fracture failure, aggravated corrosion phenomena, and high prices, and achieve high comprehensive mechanical properties, consistent corrosion resistance, and overall corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

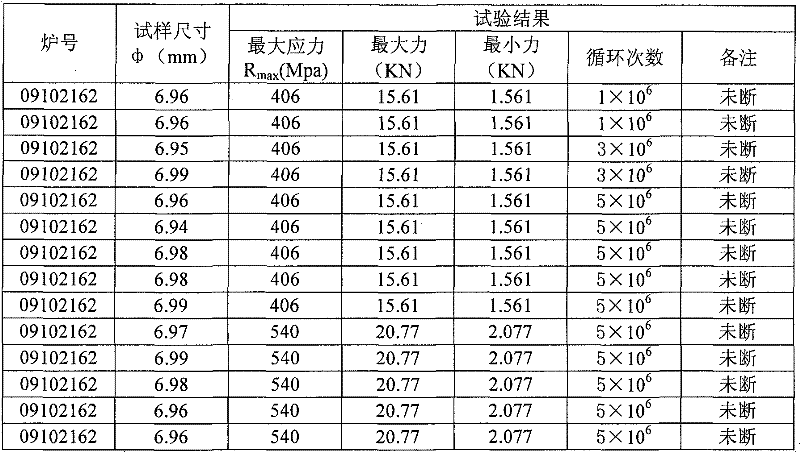

Examples

Embodiment

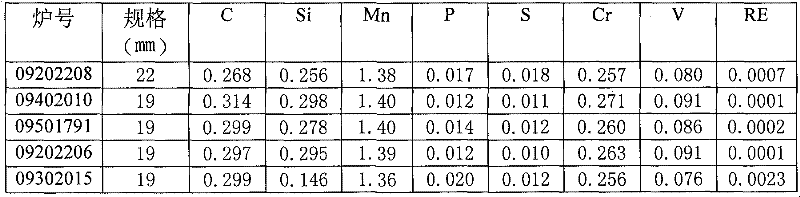

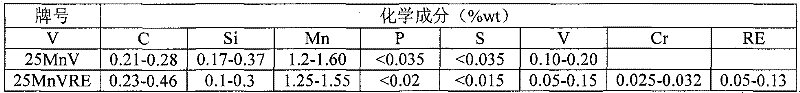

[0011] Example: The material of the grade D rod is 25MnV as the matrix chemical composition formula, and appropriate rare earth is added.

[0012] (1) Production process:

[0013] Hot metal pretreatment-converter smelting-aluminum manganese silicon deoxidation-feeding rare earth wire in the early stage of LF refining-feeding Si-Ca wire after refining-billet continuous casting-slab heating-bar continuous rolling-length cutting-inspection-packing and storage.

[0014] (2) Production and smelting operations:

[0015] In the process of converter tapping, Cr-iron alloying is used; Al-Mn-Si is deoxidized, rare earth wire is fed in the early stage of LF refining, Si-Ca wire is fed after refining, and soft blowing is maintained for a certain period of time after refining; the ladle is cast on the casting table, with a specification of 150mm× 150mm.

[0016] Because the steel of the present invention is made of the material of grade D rod with 25MnV material as the matrix chemical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com