Calcium fluoride based fluorinated catalyst and application thereof

A technology based on fluorination catalysts and catalysts, applied in the direction of physical/chemical process catalysts, organic chemistry, chemical instruments and methods, etc., can solve the problems of low catalytic activity of catalysts, poor catalytic activity, poor catalytic activity, etc., and achieve simple preparation process , less industrial waste, good catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

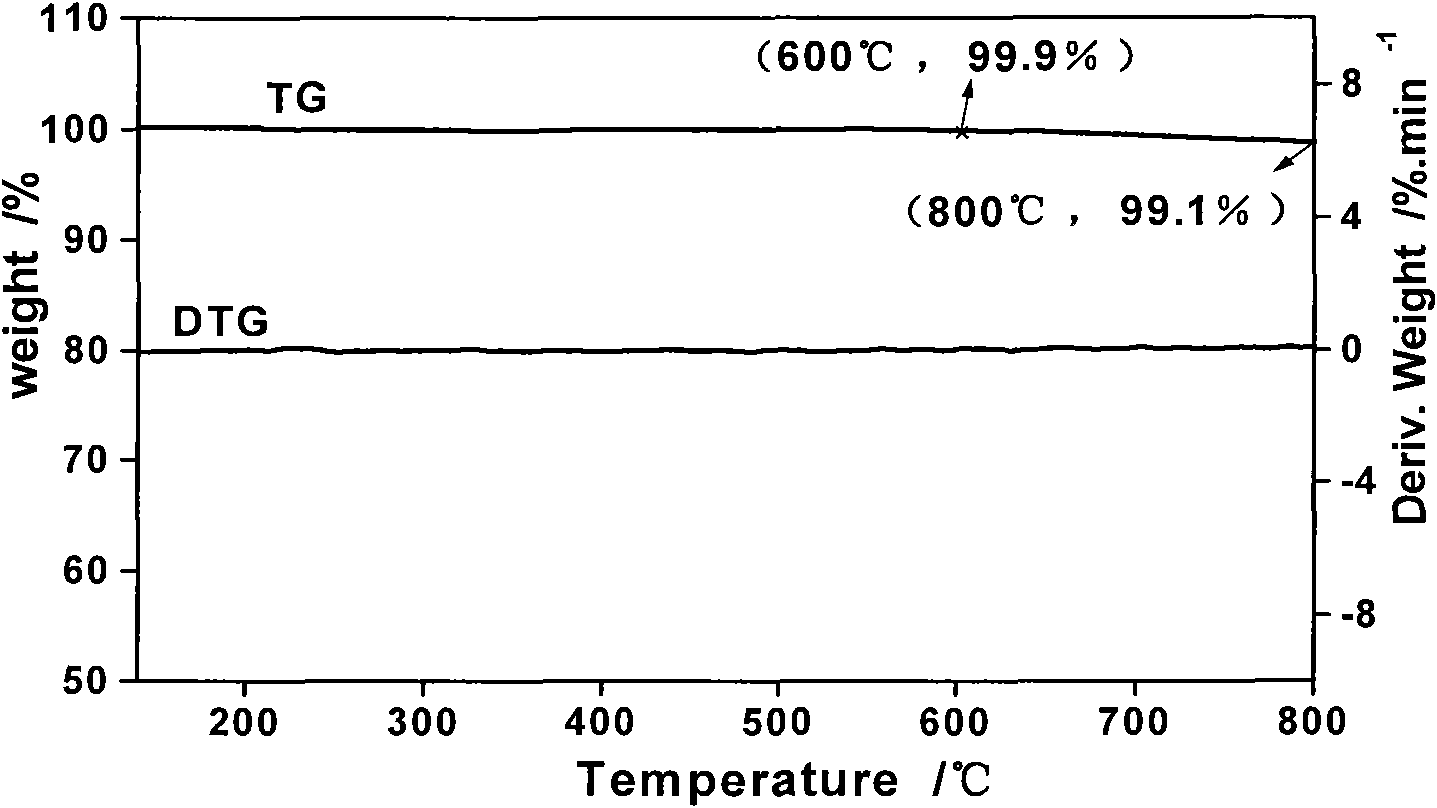

Method used

Image

Examples

Embodiment 1

[0033] Implementation with reference to the mass percent composition of the following fluorination catalyst precursor:

[0034] FeCl 3 30.0%

[0035] NiCl 2 0.5%

[0036] CaCO 3 69.5%

[0037] Ferric chloride and NiCl 2 Dissolve in water to make impregnation solution, add CaCO 3 , impregnated for 1 hour, evaporated to dryness by rotary evaporation, and dried in an oven at 120°C for 8 hours to obtain a catalyst precursor, which was calcined in a muffle furnace at 450°C for 8 hours, and then loaded into a tubular reactor , the temperature was raised to 300°C, fluorinated with hydrogen fluoride gas for 1 hour, and then the temperature was raised to 400°C at a heating rate of 1°C / min, and the fluorination was continued for 8 hours to prepare a calcium fluoride-based fluorination catalyst.

[0038] In a nickel tube fixed-bed tubular reactor with an internal diameter of 38mm, 60ml of the above-mentioned calcium fluorid...

Embodiment 2

[0041] The preparation process of the catalyst is basically the same as in Example 1, except that the NiCl 2 Change to CoCl 2 , with reference to the mass percent composition of the following fluorination catalyst precursor:

[0042] FeCl 3 30.0%

[0043] CoCl 2 0.5%

[0044] CaCO 3 69.5%

[0045] The obtained catalyst precursor is roasted and fluorinated with HF to prepare a calcium fluoride-based fluorination catalyst.

[0046] In a nickel tube fixed-bed tubular reactor with an internal diameter of 38 mm, 60 ml of the above-mentioned prepared fluorination catalyst are charged, and HF and HCC-240fa are introduced to react, and the molar ratio of HF / HCC-240fa is controlled to be 10: 1. The contact time is 5.5 seconds, the reaction temperature is 200°C, and after 20 hours of reaction, the reaction product is washed with water and alkali to remove HCl and HF, and the conversion rate of HCC-240fa is 100% according to gas chromatography a...

Embodiment 3

[0048] The preparation process of the catalyst is basically the same as in Example 1, except that the NiCl 2 Change to ZnCl 2 , with reference to the mass percent composition of the following fluorination catalyst precursor:

[0049] FeCl 3 30.0%

[0050] ZnCl 2 0.5%;

[0051] CaCO 3 69.5%

[0052] The obtained catalyst precursor is roasted and fluorinated with HF to prepare a calcium fluoride-based fluorination catalyst.

[0053] Inside diameter is in the nickel tube fixed-bed tubular reactor of 38mm, the above-mentioned fluorination catalyst that packs into 60ml makes, feeds HF and tetrachloropropane to react, and the mol ratio of control HF / tetrachloropropane is 15: 1, The contact time is 3.2 seconds, the reaction temperature is 260°C, and after 20 hours of reaction, the reaction product is washed with water and alkali to remove HCl and HF, and the conversion rate of tetrachloropropane is 100% according to gas chromatography analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com