Star polymer nano-medicament carrier preparation used for intracellular medicament delivery and preparation method thereof

A nano-drug carrier and star-shaped polymer technology, which is applied in the fields of polymer materials and medical engineering, can solve the problems of large side effects and low drug bioavailability, achieve good micelle stability, and facilitate encapsulation and delivery. The effect of the simple and easy synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

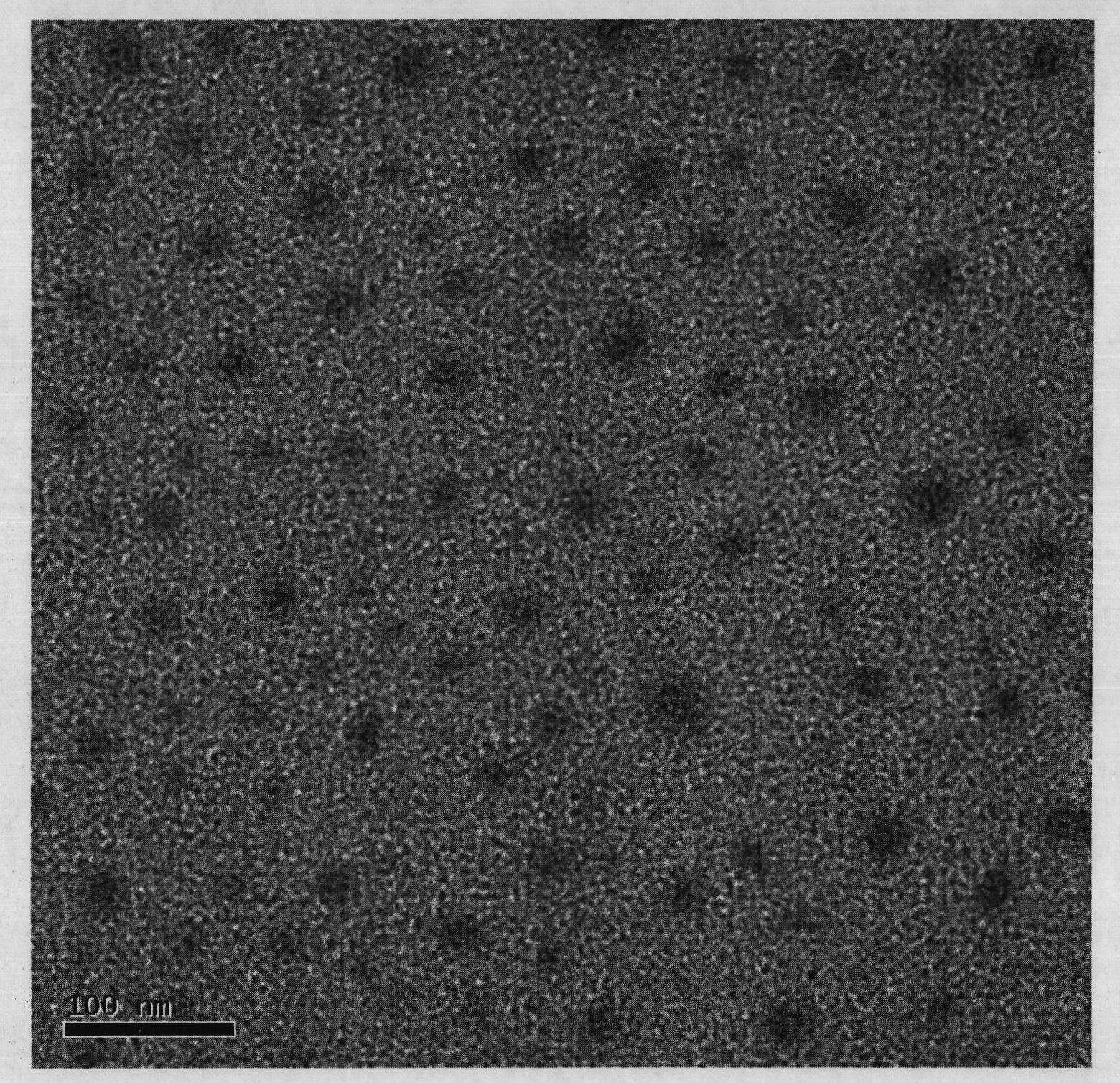

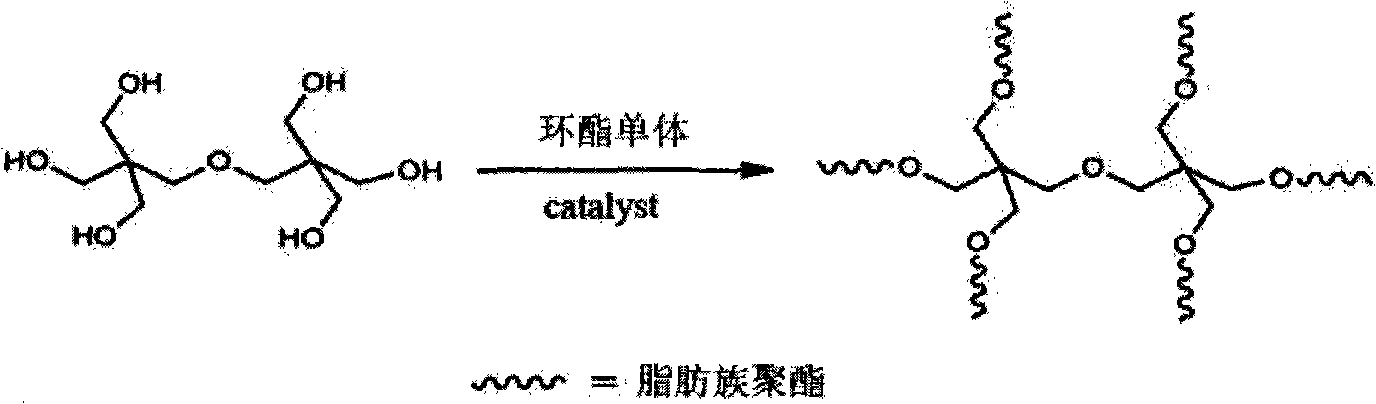

[0049] Embodiment 1 Preparation of amphiphilic six-arm star-shaped block copolymer nano drug carrier preparation

[0050] a) Add dry dipentaerythritol and ε-caprolactone into the polymerization tube at a molar ratio of 1:120, under anhydrous and anaerobic conditions, add stannous octoate according to 0.1% of the total molar weight of the monomers, under nitrogen Under protection, solution polymerization was carried out in dry toluene, the polymerization temperature was 110°C, and the polymerization time was 20 hours. The obtained polymer was precipitated, filtered, washed, and vacuum-dried to obtain a six-armed star-shaped polyhexene containing terminal hydroxyl groups. Lactone (6sPCL), number average molecular weight 13000.

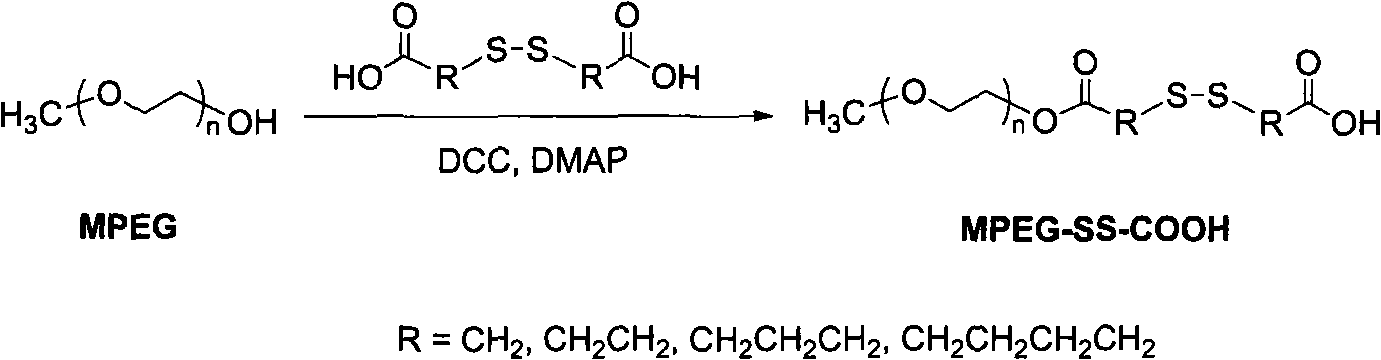

[0051] b) Polyethylene glycol monomethyl ether (MPEG), dithiodipropionic acid, N, N-dicyclohexylcarboimide (DCC) and 4-dimethylaminopyridine (DMAP) with a molecular weight of 2000 The ratio (molar ratio) of 1:5:5:1 was dissolved in dry dichloromethane, ...

Embodiment 2

[0054] Embodiment 2 Preparation of amphiphilic four-arm star-shaped block copolymer nano drug carrier preparation

[0055] a) Add dry pentaerythritol and L-lactide into the polymerization tube at a molar ratio of 1:70, under anhydrous and anaerobic conditions, add stannous octoate according to 0.1% of the total molar weight of the monomers, under nitrogen protection The bulk polymerization was carried out at 120°C, and the polymerization time was 24 hours. The obtained polymer was precipitated, filtered, washed, and vacuum-dried to obtain a four-armed star-shaped polylactic acid (4sPLLA) containing terminal hydroxyl groups. The number average molecular weight 9600.

[0056] b) Dissolving polyethylene glycol monomethyl ether (MPEG), dithiodibutyric acid, DCC and DMAP with a molecular weight of 1500 in dry dichloromethane at a ratio (molar ratio) of 1:4:4:1, The reaction was stirred at 40°C for 40 hours. After the reaction finishes, remove the precipitate by filtration, concen...

Embodiment 3

[0059] Example 3 Preparation of amphiphilic three-arm star-shaped block copolymer nano drug carrier preparation

[0060] a) Dry glycerol and D, L-lactide are added into the polymerization tube at a molar ratio of 1:50, under anhydrous and oxygen-free conditions, stannous octoate is added according to 0.15% of the total molar weight of the monomers, Bulk polymerization was carried out under the protection of nitrogen, the polymerization temperature was 125 ° C, and the polymerization time was 22 hours. The prepared polymer was precipitated, filtered, washed, and vacuum-dried to obtain a three-arm star polylactic acid (3sPLA) containing terminal hydroxyl groups. The number average molecular weight is 6800.

[0061] b) Dissolving polyethylene glycol monomethyl ether (MPEG), dithiodibutyric acid, DCC and DMAP with a molecular weight of 5000 in dry tetrahydrofuran at a ratio of 1:6:6:1 (molar ratio) at 35 The reaction was stirred at °C for 45 hours. After the reaction, remove the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com