Preparation method of low melting point drug solid dispersion

A technology of solid dispersion and low melting point, which can be applied to medical preparations containing non-active ingredients, medical preparations containing active ingredients, and drug delivery, etc. Bioavailability, environmental friendliness, effect of reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

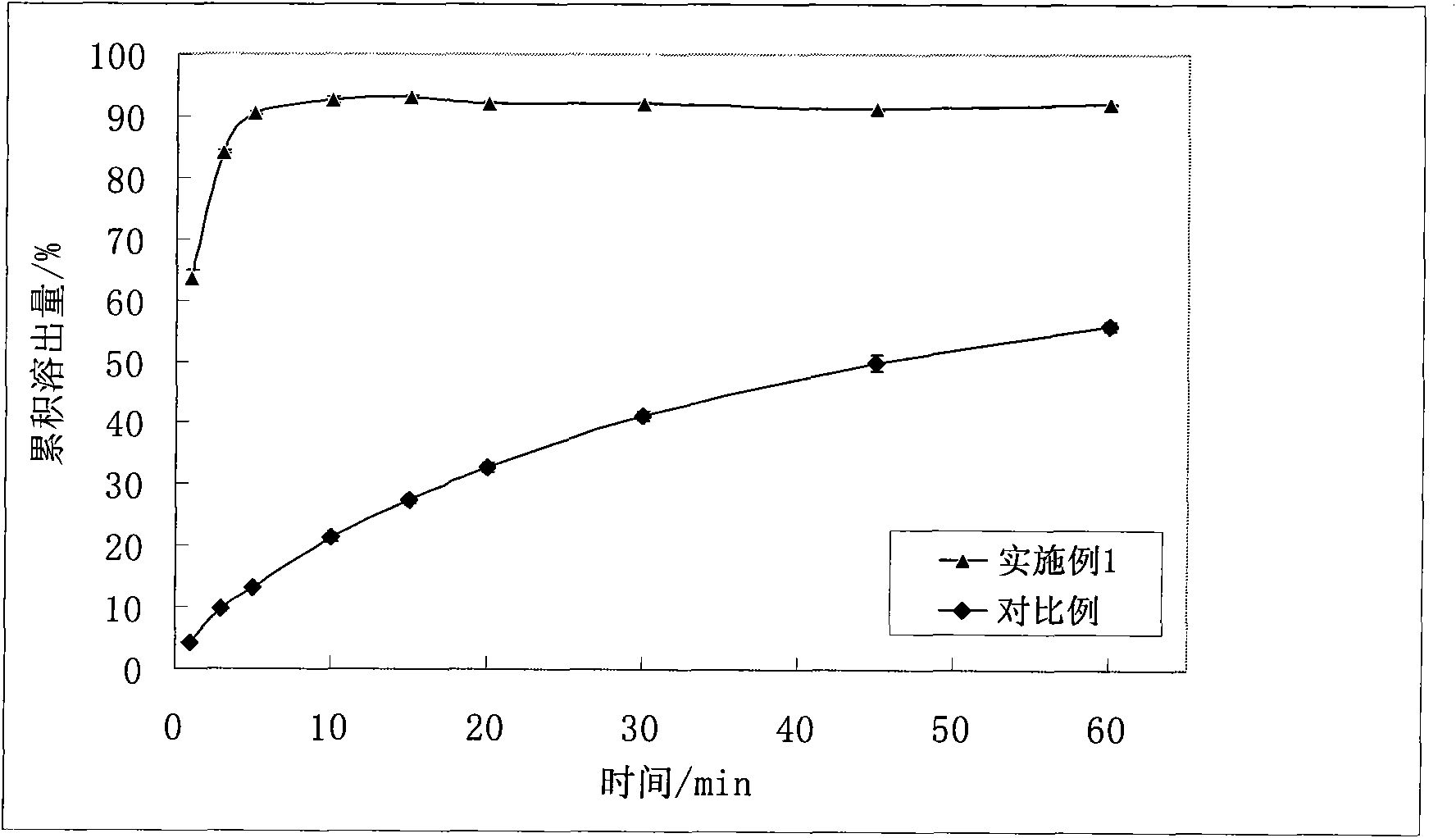

Embodiment 1

[0024] α-Asarone 30g

[0025] Low-substituted hydroxypropyl cellulose (LH-21) 236.4g

[0026] Sodium carboxymethyl starch 24g

[0028] Magnesium Stearate 1.5g

[0029] Micronized silica gel 0.6g

[0030] Sodium Lauryl Sulfate 4.5g

[0031] Prepare the raw material α-asarone and each auxiliary material according to the above prescription and pass through an 80-mesh sieve, mix evenly, seal, keep the temperature at 65°C for 1.5h, cool to room temperature, and obtain a solid dispersion, lightly crush and pass through a 40-mesh sieve Sieve, and compress into 1000 tablets according to the weight of each tablet of 0.3g, to obtain immediate-release α-asarone tablets.

Embodiment 2

[0033] Ibuprofen 100g

[0034] Microcrystalline Cellulose (PH101) 135.5g

[0035] Sodium carboxymethyl starch 12g

[0037] Magnesium stearate 0.7g

[0038] Micronized silica gel 0.3g

[0039] The raw material ibuprofen and various auxiliary materials were prepared according to the above prescription and passed through an 80 mesh sieve, mixed evenly, sealed, kept at a constant temperature of 85°C for 2 hours, cooled to room temperature to obtain a solid dispersion, lightly crushed, passed through a 40 mesh sieve, and Press each tablet weight 0.25g and press into 1000, obtain quick-release ibuprofen tablet.

Embodiment 3

[0041] Paeonol 40g

[0042] Low-substituted hydroxypropyl cellulose (LH-21) 229.4g

[0043] Sodium carboxymethyl starch 24g

[0045] Magnesium Stearate 1.5g

[0046] Micronized silica gel 0.6g

[0047] Sodium Lauryl Sulfate 1.5g

[0048] Prepare the raw materials and various auxiliary materials according to the above prescription and pass through a 80-mesh sieve, mix evenly, seal, keep the temperature at 60°C for 1.5h, cool to room temperature, and after obtaining a solid dispersion, lightly press and crush, pass through a 40-mesh sieve, and press Each tablet weighing 0.3 g was pressed into 1000 tablets to obtain immediate-release paeonol tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com