Method for preparing plumbum magnesium niobate-plumbum titanate ferroelectric film

A ferroelectric thin film, lead magnesium niobate technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of inferior crystalline quality and performance of the thin film, achieve good ferroelectric performance and simple preparation process , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

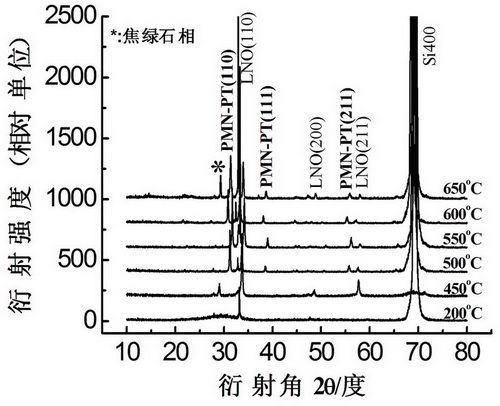

[0042] figure 1 are the substrate temperatures are room temperature 200 o C、450 o C、500 o C、550 o C、600 o C、650 o X-ray diffraction pattern of PMN-PT film grown at C. It can be seen from the figure that when the substrate temperature is lower than 450 o At C, the film contains a small amount of pyrochlore phase and is basically amorphous. When the substrate temperature reaches 500 - 600 o At C, a PMN-PT film with a (110) preferred orientation and a pure perovskite structure appears, and the preferred orientation degree can reach 71%. When the substrate temperature is 500 o At C, the (110) diffraction peak of the PMN-PT film grown on the LNO / Si substrate is almost consistent with the bulk peak, which indicates that the stress has been basically released. Compared with the bulk peak, 550 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com