Method for preparing silicon-based light emitting diode (LED)

A light-emitting diode, silicon-based technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as inability to obtain electroluminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

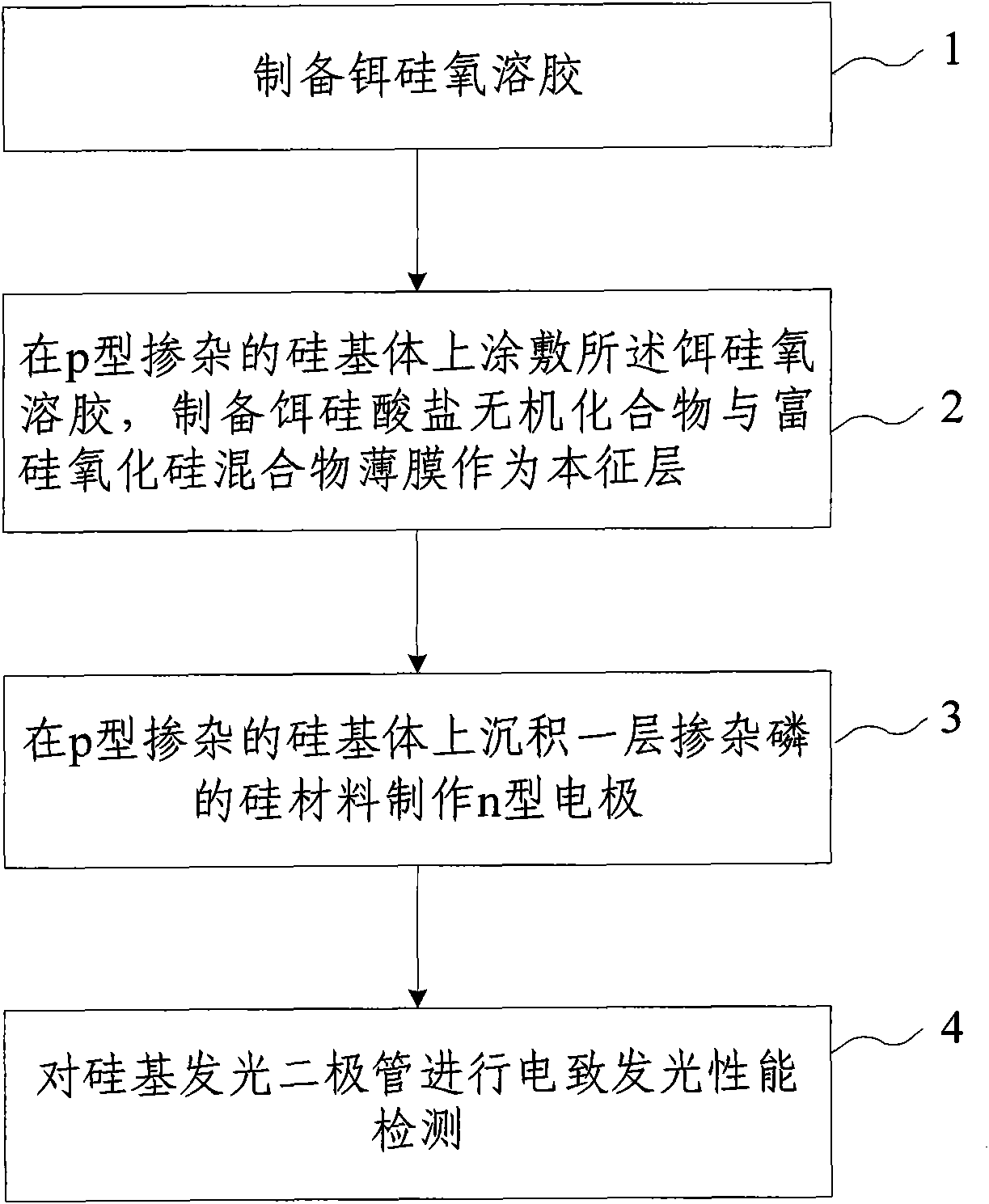

[0037] In the method for preparing a silicon-based light-emitting diode provided by the present invention, the silicon-based light-emitting diode is composed of a p-i-n structure, wherein the p-type electrode is a boron-doped silicon substrate, the n-type electrode is a phosphorus-doped silicon material, and the middle intrinsic layer Composed of erbium silicate inorganic compound and silicon-rich silicon oxide.

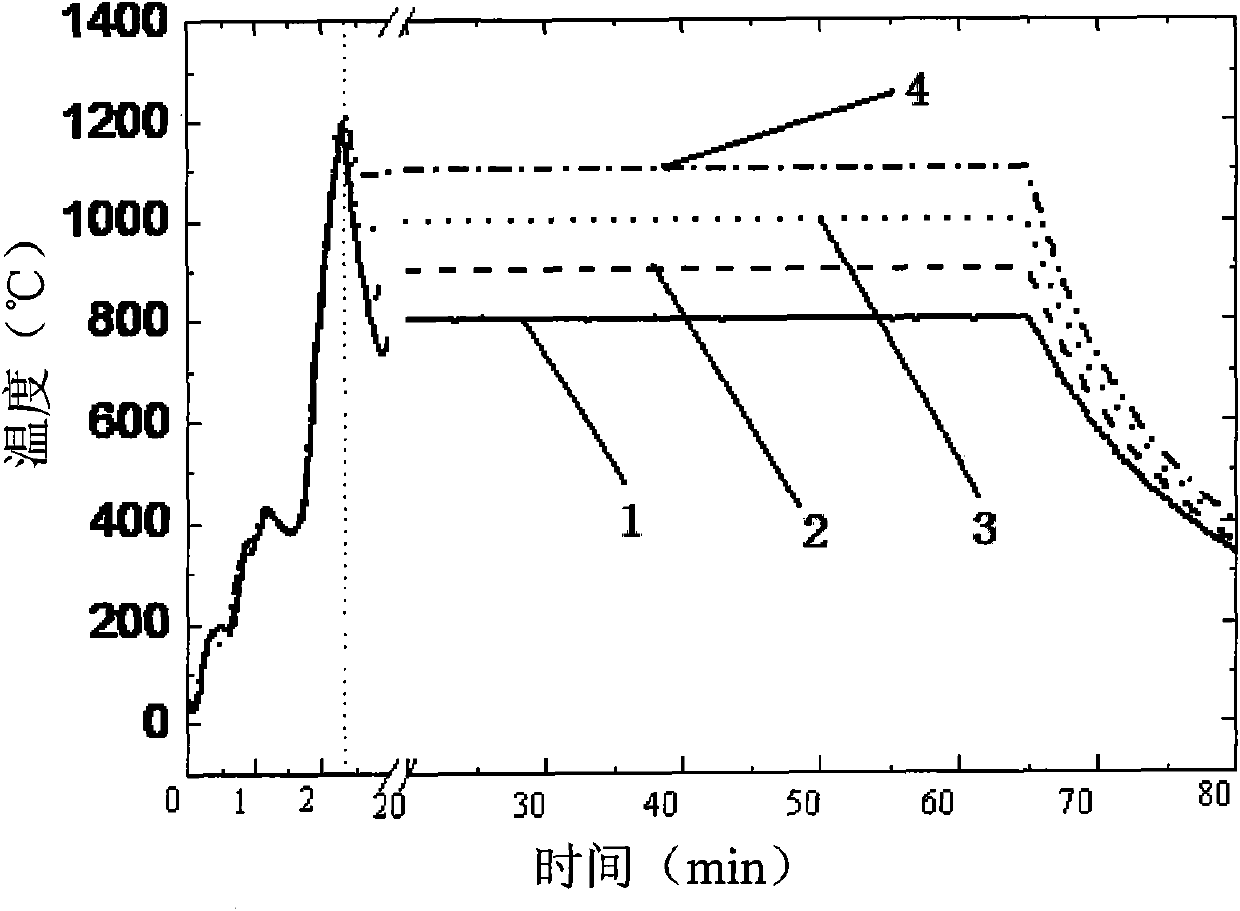

[0038] Such as figure 1 Shown is a flowchart of a method for preparing a silicon-based light-emitting diode according to an embodiment of the present invention, which includes the following steps:

[0039] S1: Preparation of erbium silica sol.

[0040] Specifically, the rare earth erbium salt is put into an alcohol solvent, stirred at a temperature of 60-70° C. for 1-3 hours, and then the obtained solution is naturally cooled to room temperature; a certain stoichiometric ratio of ethyl orthosilicate is added to continue stirring for 1 hour. -3h; then add HNO 3 Or ...

Embodiment 1

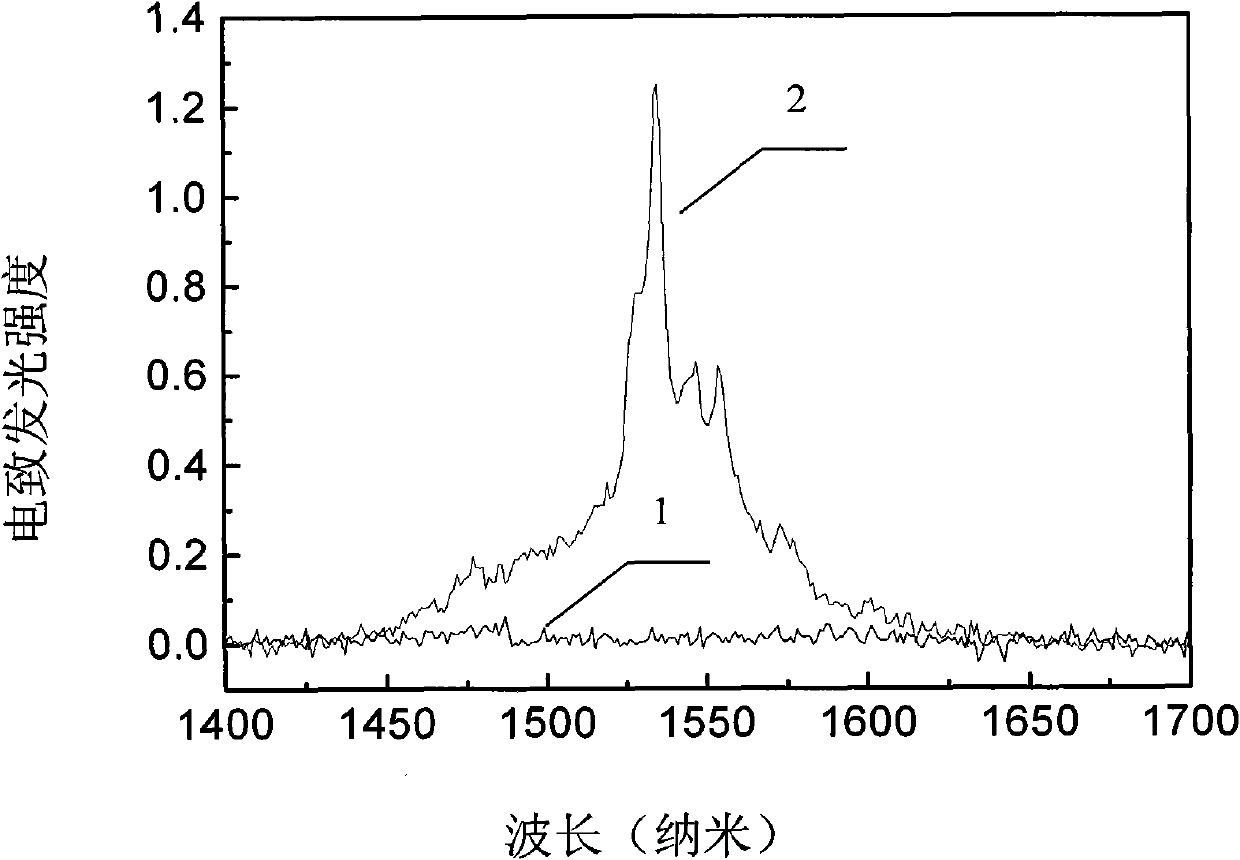

[0052] An optical communication device production unit requires to obtain a light-emitting diode with a communication wavelength of 1.53 μm, and adopts the preparation method of the new silicon-based light-emitting diode of the present invention. The steps are as follows:

[0053] S1: Preparation of erbium silica sol.

[0054] Put the rare earth erbium salt into alcohol solvent, stir at 70°C for 1 hour, wherein the molar ratio of erbium salt to alcohol is 1:20, then naturally cool the obtained solution to room temperature; Ethyl orthosilicate, continue to stir for 1h, wherein the molar ratio of erbium salt and ethyl orthosilicate is 1:1; then add HNO 3 or HCl solution, adjust the pH value to 3, and finally continue stirring at a temperature of 70° C. for 6 h until a transparent erbium silica sol is formed.

[0055] S2: coating the erbium silicate sol on the p-type doped silicon substrate to prepare a thin film of the mixture of erbium silicate inorganic compound and silicon-r...

Embodiment 2

[0061] An optical communication device production unit requires to obtain a light-emitting diode with a communication wavelength of 1.53 μm, and adopts the method of the present invention, and the steps are as follows:

[0062] S1: Preparation of erbium silica sol.

[0063] Put the rare earth erbium salt into the alcohol solvent, stir at 70°C for 1 hour, wherein the molar ratio of the erbium salt to the alcohol is 1:20, then naturally cool the resulting solution to room temperature; Ethyl silicate continued to stir for 1h, wherein the molar ratio of erbium salt to ethyl orthosilicate was 1:2; then a certain proportion of HNO was added 3 or HCl solution, adjust the pH value to 3; finally, continue to stir at a temperature of 70° C. for 4 h until a transparent erbium silica sol is formed.

[0064] S2: coating the erbium silicate sol on the p-type doped silicon substrate to prepare a thin film of the mixture of erbium silicate inorganic compound and silicon-rich silicon oxide as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com