Method for producing photoelectrochemical microfluidic detection chip of three-electrode system

A three-electrode system, photoelectrochemical technology, applied in the fields of material electrochemical variables, analytical materials, instruments, etc., can solve the problems of complex production process, high cost, and equipment time-consuming, etc., to improve catalytic efficiency, low production cost, Less time consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

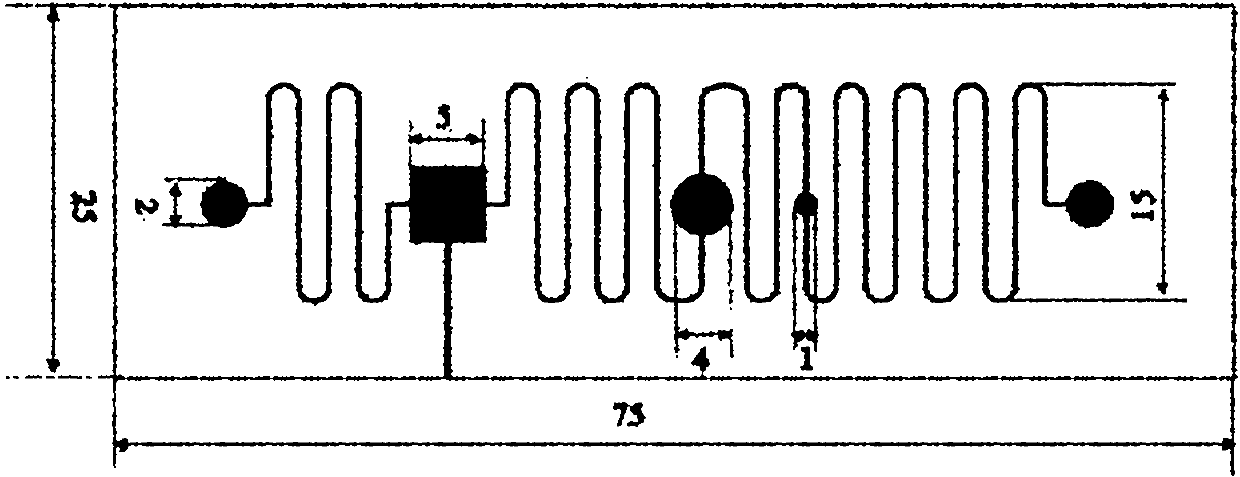

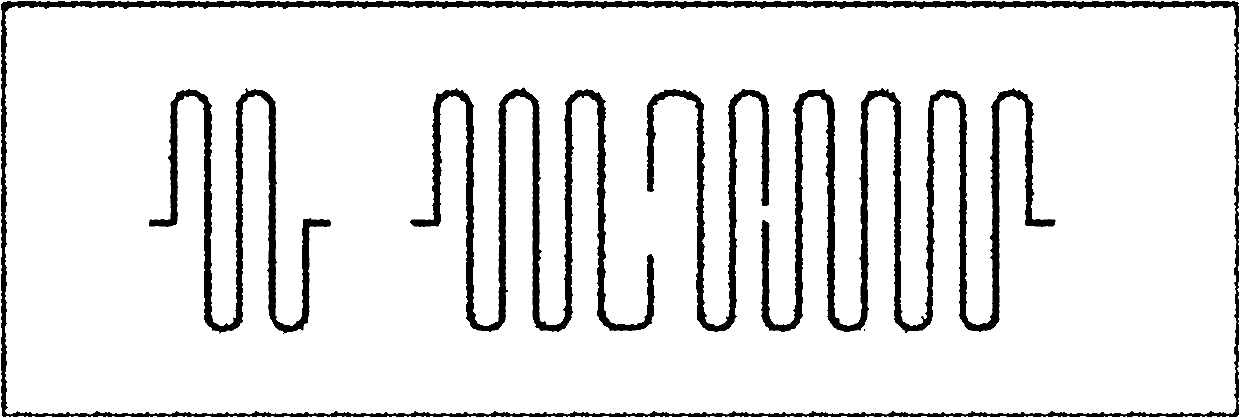

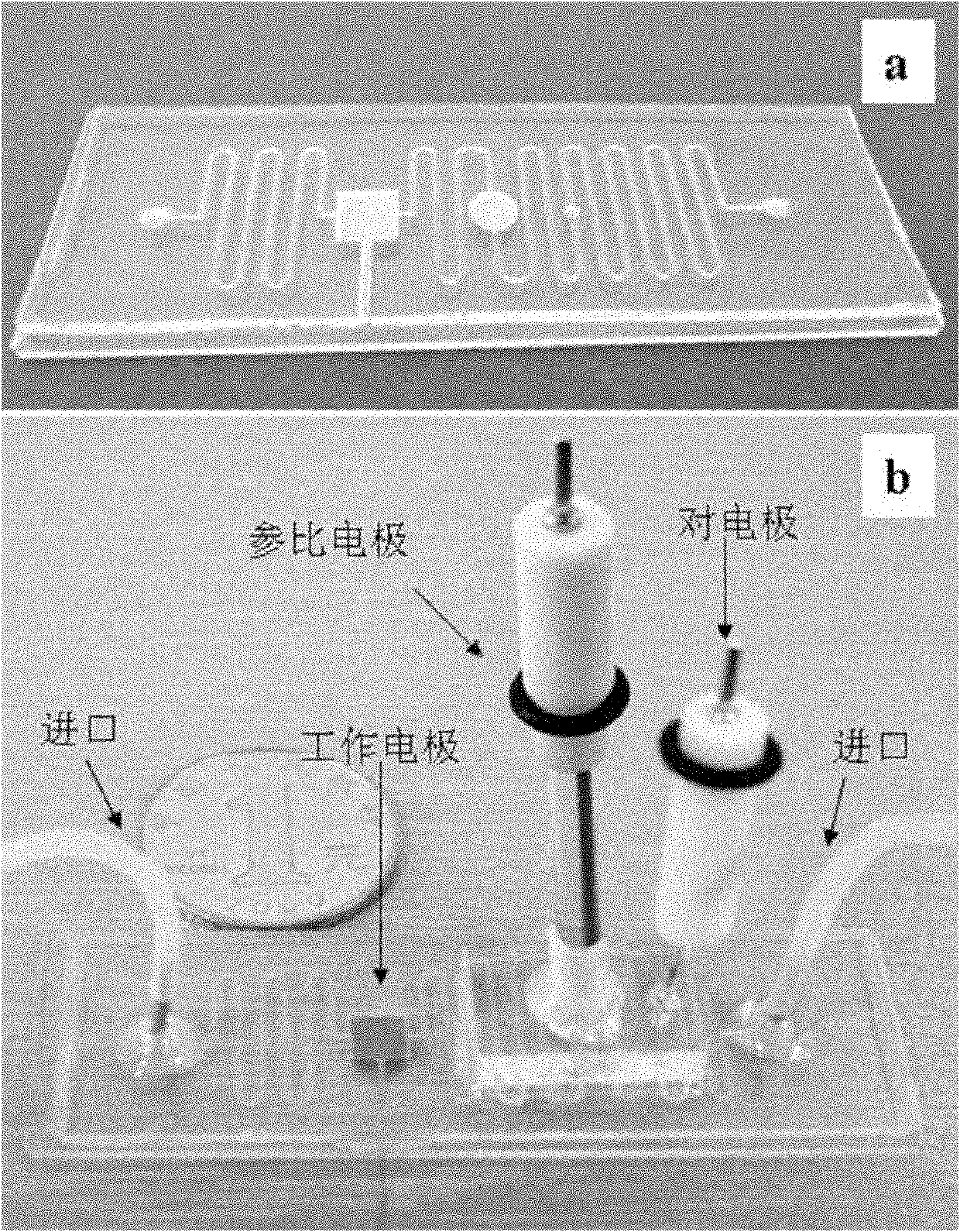

[0035] The liquid PDMS matrix and the curing agent are mixed uniformly in a mass ratio of 10:1. A glass sheet with a size of 25mm×75mm and a thickness of 1mm was adsorbed on the turntable of the homogenizer, the PDMS was poured on the glass sheet, and rotated at a speed of 1000 revolutions / min for 30 seconds. Then, the glass slide with PDMS was placed in an environment of 120°C for 6 minutes to cure the PDMS. Graphics designed according to the drawing such as figure 2 As shown, use CO 2 The laser engraves the channel on the PDMS. First sculpt as image 3 In the part shown, the laser power used is 12W, the engraving speed is 50cm / s, and the resulting channel has a depth of 0.2mm and a width of 0.2mm. Then engrave the remaining part, the laser power used is 15W, the engraving speed is 50cm / s, the depth of the resulting figure is 0.3mm, and the size is as figure 2 Shown. After the carving is completed, you get Figure 4 The substrate shown in a. Place the electrode covered wi...

Embodiment 2

[0038] The liquid PDMS matrix and the curing agent are mixed uniformly in a mass ratio of 10:1. A glass sheet with a size of 25mm×75mm and a thickness of 2mm was adsorbed on the turntable of the homogenizer, and the PDMS was poured on the glass sheet and rotated at 800 rpm for 45 seconds. Then, the glass slide loaded with PDMS was placed in an environment at 100°C for 10 minutes to cure the PDMS. Graphics designed according to the drawing such as figure 2 As shown, use CO 2 The laser engraves the channel on the PDMS. First sculpt as image 3 In the part shown, the laser power used is 15W, the engraving speed is 50cm / s, and the resulting channel has a depth of 0.3mm and a width of 0.5mm. Then engrave the remaining part, the laser power used is 15W, the engraving speed is 40cm / s, the depth of the resulting figure is 0.35mm, and the size is as figure 2 Shown. After the engraving is completed, the electrode covered with the nano-titanium dioxide active layer is placed in the wo...

Embodiment 3

[0040] The liquid PDMS matrix and the curing agent are mixed uniformly in a mass ratio of 10:1. A glass sheet with a size of 25mm×75mm and a thickness of 3mm was adsorbed on the turntable of the homogenizer, the PDMS was poured on the glass sheet, and rotated at 500 rpm for 60 seconds. Then, the glass slide loaded with PDMS was placed in an environment at 150°C for 3 minutes to cure the PDMS. Graphics designed according to the drawing such as figure 2 As shown, use CO 2 The laser engraves the channel on the PDMS. First sculpt as image 3 In the part shown, the laser power used is 20W, the engraving speed is 70cm / s, the resulting channel depth is 0.4mm, and the width is 1mm. Then engrave the remaining part, the laser power used is 20W, the engraving speed is 50cm / s, the depth of the resulting figure is 0.5mm, and the size is as figure 2 Shown. After the engraving is completed, the electrode covered with the nano-titanium dioxide active layer is placed in the working electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com