Method and device for producing high-grade nickel oxide

A high-quality, nickel oxide technology, applied in the direction of nickel oxide/nickel hydroxide, etc., can solve the problems of unstable physical performance indicators, affecting stability, uniformity, large investment in fixed assets, etc., to reduce labor intensity of workers, without Effects of leakage and loss, saving washing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

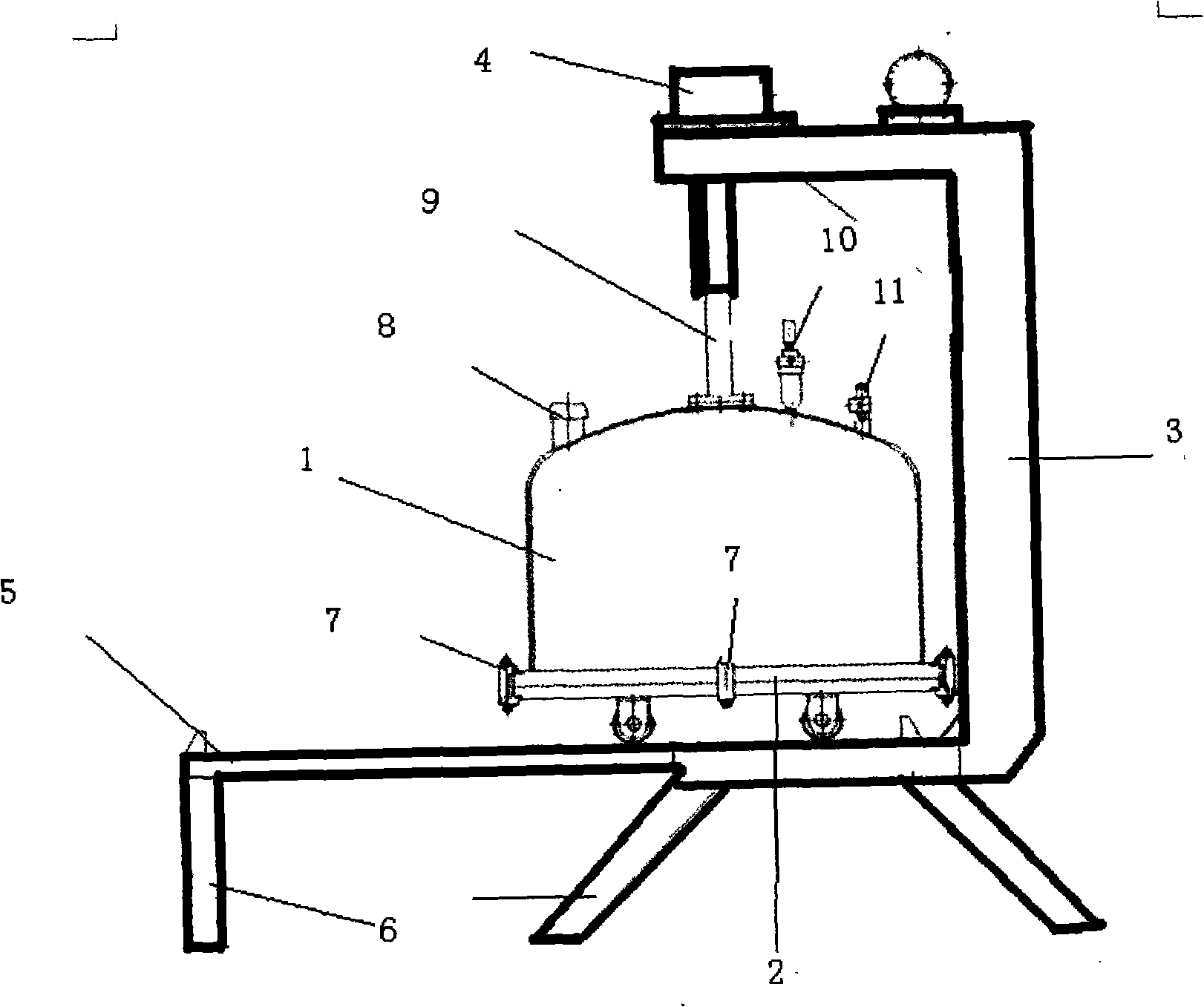

[0036] From figure 2 It can be seen that the airtight washing and filtering device required for the method of producing high-quality nickel oxide by nickel salt complex precipitation is composed of a frame 3 and a motor 4 on it, a lift pipe 9 connecting the motor 4 and the container, and a support 6 and the track 5 on it and the container; the container is composed of an upper cover 1 and a base 2, and the base 2 has many holes on which there are filter screens and filter cloth; between the upper cover 1 and the base 2 It is connected and fixed by the inner and outer locks 7; the container is placed on the track 5 on the support 6 through the rollers provided at the bottom of the base 2; the cavity at the bottom of the base 2 is provided with a drainpipe for centralized drainage; the upper cover 1 is provided with There is a feed port 8, a water inlet 11, a lift pipe 9 connected to the motor, and an air intake valve 10 connected to the air compressor.

Embodiment 2

[0038] From figure 1 Visible, the method for producing high-quality nickel oxide by nickel salt complex precipitation of the present invention, its steps are as follows:

[0039] (1) configuration concentration is the nickel sulfate aqueous solution a of 1.2mol / L;

[0040] (2) configuration concentration is the ammonia solution b of 1.0mol / L;

[0041] (3) configuration concentration is the sodium hydroxide solution c of 1.0mol / L;

[0042] (4) The above-mentioned three kinds of solutions are respectively according to the flow rate: a solution is 60L / h, b solution is 10L / h, c solution is 30L / h and is continuously pumped into the reactor;

[0043] (5) Turn on the reactor agitator, control the temperature in the reactor to be 20° C., the pH value is 7, and the stirring speed is 100 rpm to carry out precipitation reaction and grain growth;

[0044] (6) Take out 100ml mixed solution from the reaction kettle of step (5) every half hour, carry out solid-liquid separation by Buchne...

Embodiment 3

[0048] From figure 1 Visible, the present invention produces the method for high-quality nickel oxide with nickel salt complex precipitation, and its steps are as follows:

[0049] (1) configuration concentration is the nickel sulfate aqueous solution a of 2.8mol / L;

[0050] (2) configuration concentration is the ammonia solution b of 10mol / L;

[0051] (3) configuration concentration is the sodium hydroxide solution c of 35mol / L;

[0052] (4) The above-mentioned three kinds of solutions are respectively according to the flow rate: a solution flow rate is 260L / h; b solution flow rate is 120L / h; c solution flow rate is continuously pumped into the reactor at 200L / h;

[0053] (5) Turn on the reactor stirrer, control the temperature in the reactor to be 70° C., the pH value to be 11.5, and the stirring speed to be 180 rpm to carry out precipitation reaction and grain growth;

[0054] (6) Take out 150ml mixed solution from the reaction kettle in step (5) at intervals of 1 hour,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com